GEPPCBug Firmware Package User’s Manual Parts 1 & 2

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Motorola, Inc. assumes no liability resulting from any omissions in this document,

or from the use of the information obtained therein. Motorola reserves the right to

revise this document and to make changes from time to time in the content hereof

without obligation of Motorola to notify any person of such revision or changes.

No part of this material may be reproduced or copied in any tangible medium, or

stored in a retrieval system, or transmitted in any form, or by any means, radio,

electronic, mechanical, photocopying, recording or facsimile, or otherwise,

without the prior written permission of Motorola, Inc.

It is possible that this publication may contain reference to, or information about

Motorola products (machines and programs), programming, or services that are

not announced in your country. Such references or information must not be

construed to mean that Motorola intends to announce such Motorola products,

programming, or services in your country.

Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S.

Government, the following notice shall apply unless otherwise agreed to in

writing by Motorola, Inc.

Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013.

Motorola, Inc.

Computer Group

2900 South Diablo Way

Tempe, Arizona 85282

Preface

The PPCBug Firmware Package User’s Manual provides information on the PPCBug

firmware, the start-up and boot routines, the debugger commands, the one-line

assembler/disassembler, and the debugger system calls. All information

contained herein is specific to Motorola’s PowerPC™-based boards: MVME230x

VME Processor Modules, MVME260x Single Board Computers, MVME3604 VME

Processor Modules, MVME4604 VME Dual Processor Modules, MTX Embedded

ATX Motherboards, MCP750 CompactPCI, and PMCspan PCI expansion boards.

In this manual, they are collectively referred to as the PowerPC board or board.

This manual covers release 3.5, and earlier versions, of PPC1Bug.

This document is bound in two parts. Part 1 (PPCBUGA1/UM4) contains the Table

of Contents, List of Figures, List of Tables, and Chapters 1 through 3. Part 2

(PPCBUGA2/UM4) contains Chapters 4 and 5, Appendixes A through H, and the

Index.

The diagnostics are covered in the PPCBug Diagnostics Manual (PPCDIAA/UM2).

A basic knowledge of computers and digital logic is assumed. Refer to Appendix

A, Related Documentation, of this manual for a list of documents that may provide

helpful information.

This manual is intended for anyone who designs OEM systems, supplies

additional capability to an existing compatible system, or works in a lab

environment for experimental purposes.

Motorola® and the Motorola symbol are registered trademarks of Motorola, Inc.

PowerPC™ is a trademark of IBM, and is used by Motorola with permission.

AIXTM is a trademark of IBM Corp.

All other products mentioned in this document are trademarks or registered

trademarks of their respective holders.

Conventions

The following conventions are used in this document:

bold

is used for user input that you type just as it appears. Bold is also used for

commands, options and arguments to commands, and names of programs,

directories, and files.

italic

is used for names of variables to which you assign values. Italic is also used

for comments in screen displays and examples.

courier

is used for system output (e.g., screen displays, reports), examples, and

system prompts.

Return or ‘the Return key’

represents the Enter, Return, or Carriage Return key.

CTRL

represents the Control key. Execute control characters by pressing the

CTRL key and the letter simultaneously, e.g., CTRL-d.

|

Separates two or more items that you can select from (one only).

[ ]

encloses an optional item that may occur zero or one time.

{ }

encloses an optional item that may occur zero or more times.

A character precedes a data or address parameter to specify the numeric format,

as follows (if not specified, the format is hexadecimal):

$ dollar a hexadecimal character.

0x Zero-x

% percent a binary number.

& ampersand a decimal number.

Safety Summary

Safety Depends On You

The following general safety precautions must be observed during all phases of operation, service, and

repair of this equipment. Failure to comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and intended use of the equipment.

Motorola, Inc. assumes no liability for the customer's failure to comply with these requirements.

The safety precautions listed below represent warnings of certain dangers of which Motorola is aware. You,

as the user of the product, should follow these warnings and all other safety precautions necessary for the

safe operation of the equipment in your operating environment.

Ground the Instrument.

To minimize shock hazard, the equipment chassis and enclosure must be connected to an electrical ground.

The equipment is supplied with a three-conductor ac power cable. The power cable must be plugged into

an approved three-contact electrical outlet. The power jack and mating plug of the power cable meet

International Electrotechnical Commission (IEC) safety standards.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in the presence of flammable gases or fumes. Operation of any electrical

equipment in such an environment constitutes a definite safety hazard.

Keep Away From Live Circuits.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or

other qualified maintenance personnel may remove equipment covers for internal subassembly or

component replacement or any internal adjustment. Do not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To

avoid injuries, always disconnect power and discharge circuits before touching them.

Do Not Service or Adjust Alone.

Do not attempt internal service or adjustment unless another person capable of rendering first aid and

resuscitation is present.

Use Caution When Exposing or Handling the CRT.

Breakage of the Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion).

To prevent CRT implosion, avoid rough handling or jarring of the equipment. Handling of the CRT should

be done only by qualified maintenance personnel using approved safety mask and gloves.

Do Not Substitute Parts or Modify Equipment.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any

unauthorized modification of the equipment. Contact your local Motorola representative for service and

repair to ensure that safety features are maintained.

Dangerous Procedure Warnings.

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual.

Instructions contained in the warnings must be followed. You should also employ all other safety

precautions which you deem necessary for the operation of the equipment in your operating environment.

!

WARNING

Dangerous voltages, capable of causing death, are present in this

equipment. Use extreme caution when handling, testing, and

adjusting.

The computer programs stored in the Read Only Memory of this device contain

material copyrighted by Motorola Inc., 1995, 1996, and 1997, and may be used only

under a license such as those contained in Motorola’s software licenses.

The software described herein and the documentation appearing herein are

furnished under a license agreement and may be used and/or disclosed only in

accordance with the terms of the agreement.

The software and documentation are copyrighted materials. Making unauthorized

copies is prohibited by law. No part of the software or documentation may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated

into any language or computer language, in any form or by any means without the

prior written permission of Motorola, Inc.

Disclaimer of Warranty

Unless otherwise provided by written agreement with Motorola, Inc., the software

and the documentation are provided on an “as is” basis and without warranty.

This disclaimer of warranty is in lieu of all warranties whether express, implied, or

statutory, including implied warranties of merchantability or fitness for any

particular purpose.

!

WARNING

This equipment generates, uses, and can radiate electromagnetic energy. It may cause or be susceptible to electromagnetic interference (EMI) if not installed and used in a

cabinet with adequate EMI protection.

© Copyright Motorola, Inc. 1996, 1997

All Rights Reserved

Printed in the United States of America

December 1997

PPCBug Overview

PPCBug is a powerful evaluation and debugging tool for systems

built around the Motorola PowerPC microprocessors. PPCBug

firmware consists of three parts:

❏ Command-driven user-interactive software debugger. It is

hereafter referred to as the debugger, which is described in this

manual. Debugging commands are available for loading and

executing user programs under complete operator control for

system evaluation.

❏ Command-driven diagnostic package for testing and

troubleshooting the PowerPC board, which is hereafter called

the diagnostics. Refer to the PPC1Bug Diagnostics Manual.for

information on the diagnostics and the diagnostics utilities

and self-tests.

❏ MPU, firmware, and hardware initialization routines, which

are described in this manual.

The PPCBug firmware is implemented on the following Motorola

PowerPC-based products:

❏ MVME230x VME Processor Modules

❏ MVME260x Single Board Computers

❏ MVME3604 VME Processor Modules

❏ MVME4604 VME Dual Processor Modules

❏ MTX Embedded ATX Motherboards

❏ MCP750 PowerPC Single Board Computers

A PMCspan board added to any of these also interfaces with PPCBug.

They are collectively referred to in this manual as the PowerPC board

or board.

The debugger includes:

❏ Commands for display and modification of memory

❏ Breakpoint and tracing capabilities

❏ Assembler and disassembler useful for patching programs

Various PPCBug routines that handle I/O, data conversion, and

string functions are available to user programs through the System

Call handler.

Because PPCBug is command-driven, it performs its various

operations in response to user commands entered at the keyboard.

Comparison with other Motorola Bugs

The PPCBug is similar to previous Motorola firmware packages

(e.g., MVME147Bug, MVME167Bug, MVME187Bug), with

differences due to microprocessor architectures. These differences

are primarily reflected in the instruction mnemonics, register

displays, addressing modes of the assembler/disassembler, and

argument passing to the system calls.

PPCBug Implementation

PPCBug is written largely in the C programming language,

providing benefits of portability and maintainability. Where

necessary, the assembly language has been used in separately

compiled program modules that deal with processor-specific

issues. No mixed-language modules are used.

Physically, PPCBug is contained in two socketed 32-pin PLCC

Flash devices that together provide 1MB (256KB words) of storage.

PPCBug uses the entire memory contained in the two devices.

The executable code is checksummed at every power-on or reset

firmware entry. The result is checked with a pre-calculated

checksum contained in the last 16-bit word of the Flash image.

!

Caution

Although a command to allow the erasing and

reprogramming of this Flash memory is available to

you, keep in mind that reprogramming any portion of

Flash memory will erase everything currently contained

in Flash, including PPCBug.

Memory Requirements

The debugger requires approximately 768KB of read/write

memory (i.e., DRAM). The debugger will allocate this memory

from the top of memory. For example, on a system which contains

64MB ($04000000) of read/write memory, the debugger's memory

page will be located at $03F80000 to $03FFFFFF.

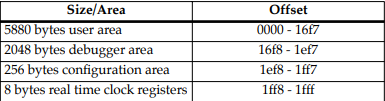

Size and Address Requirements for NVRAM

Currently, Motorola uses the SGS-Thompson Timekeeper SRAM

device (48T559), or equivalent. This is used on the PowerPlus

boards and is structured by the Debugger as follows:

NVRAM = 8192 bytes total size (with rtc)

Address ranges include:

Set-up

Refer to the board installation and use manual for information on

installing the hardware, configuring jumpers, and assigning the

console monitor.

Start-up

At either power-up or system reset, PPCBug performs the MPU,

hardware, and firmware initialization process (refer to MPU,

Hardware, and Firmware Initialization on page 1-5). This process

includes a checksum of the FLASH memory contents.

The following types of messages are displayed on the firmware

console during the initialization process:

Copyright Motorola Inc. 1988 - 1997, All Rights Reserved

PPC1 Debugger/Diagnostics Release Version 3.x - xx/xx/xx/RMxx

COLDStart

Local Memory Found =04000000 (&67108864)

MPU Clock Speed =167Mhz

BUS Clock Speed =67Mhz

Reset Vector Location : ROM Bank B

Mezzanine Configuration: Single-MPU

Current 60X-Bus Master : MPU0

Idle MPU(s) : NONE

System Memory: 64MB, ECC Enabled (ECC-Memory Detected)

L2 Cache: NONE

PPC1-Bug>

At this point, PPCBug is waiting for you to enter one of the

commands described in Chapter 3 of this manual.

PPCBug may alternatively be configured via the ENV command to

run selftest and/or autoboot automatically during startup. If so,

then PPCBug will instead behave as follows:

The system pauses five seconds, during which you may terminate

start-up, and exit to the diagnostics prompt, by pressing ESC or the

Break key

The system performs the self test diagnostics if you do not

terminate system start-up. Upon successful completion of these

tests, the system pauses another five seconds. You may terminate

start-up, and exit to the diagnostics prompt, by pressing ESC or the

Break key.

If you do not terminate system start-up, the system begins the boot

routine that has been set up in the ENV command, either NVRAM

Boot List Boot, Auto Boot, ROMboot, or Network Auto Boot.

If the self-tests fail, various error messages appear, and the

diagnostics prompt appears.

Refer to Chapter 3 for information on setting the ENV command

parameters.

MPU, Hardware, and Firmware Initialization

The MPU, hardware, and firmware initialization process is

performed by the PPCBug power-up or system reset. The steps

below are a high-level outline; not all of the detailed steps are listed.

1. Set MPU.MSR to known value.

2. Invalidate the MPU's data/instruction caches.

3. Clear all segment registers of the MPU.

4. Clear all block address translation registers of the MPU.

5. For “dual CPU only” boards (MVME460x or MTX), catch one

CPU of a dual CPU and place it in a waiting loop.

6. Initialize the MPU bus to PCI bus bridge device.

7. Initialize the PCI bus to ISA bus bridge device.

8. Calculate the external bus clock speed of the MPU.

9. Delay for 750 milliseconds.

10. Determine the CPU board type.

11. Size the local read/write memory (i.e., DRAM).

12. Initialize the read/write memory controller

13. Set base address of memory to $00000000.

14. Retrieve the speed of read/write memory from NVRAM.

15. Initialize read/write memory controller with the speed of

read/write memory.

16. Retrieve the speed of read only memory (i.e., FLASH) from

NVRAM.

17. Initialize read only memory controller with the speed of read

only memory.

18. Enable the MPU's instruction cache.

19. Copy the MPU's exception vector table from $FFF00000 to

$00000000.

20. Initialize the SIO (PC87303/PC87307/PC87308) resources'

base addresses for boards that have the SIO device.

21. Initialize the Z8536 device if the board has the device.

22. Verify MPU type.

23. Enable the super-scalar feature of the MPU (boards with

MPC604-type chips only).

24. Initialize the Keyboard Controller

(PC87303/PC87307/PC87308) for boards that have the

device.

25. Determine the debugger's Console/Host ports, and initialize

the appropriate UART and Graphic devices.

26. Display the debugger's copyright message.

27. Display any hardware initialization errors that may have

occurred.

28. Checksum the debugger object, and display a warning

message if the checksum failed to verify.

29. Display the amount of local read/write memory found.

30. Verify the configuration data that is resident in NVRAM,

and display a warning message if the verification failed.

31. Calculate and display the MPU clock speed. Verify that the

MPU clock speed matches the configuration data, and

display a warning message if the verification fails.

32. Display the BUS clock speed. Verify that the BUS clock speed

matches the configuration data, and display a warning

message if the verification fails.

33. For boards that have a Keyboard Controller display

initialization errors that have occurred.

34. Probe PCI bus for supported Network devices.

35. Probe PCI bus for supported Mass Storage devices.

36. Initialize the memory/IO addresses for the supported PCI

bus devices.

37. Execute self-test, if configured.

38. Extinguish the board fail LED, if there are no self-test failures

or initialization/configuration errors.

39. Execute the configured boot routine, either ROMboot,

Autoboot, or Network Autoboot. (PowerPlus architecture

boards do not execute a configured boot routine.)

40. Execute the user interface (i.e., the PPC1-Bug> or

PPC1-Diag> prompt).

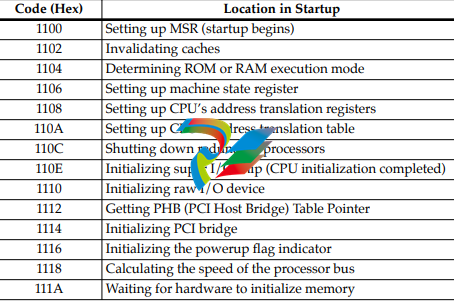

LED/Serial Startup Diagnostic Codes

These codes are displayed on seven-segment LEDs at key points in

the initialization of the hardware devices. Should the debugger fail

to come up to a prompt, the last code displayed will indicate how

far the initialization sequence had progressed before stalling. The

serial port version of the startup codes is enabled by an ENV

parameter:

Serial Startup Code Master Enable [Y/N]=N?

Under normal conditions, the startup sequence begins at 0x1100

and continues to the PPC1-Bug> prompt just after 0x11D4. RAM

initialization problems may cause the startup sequence to terminate

at the : (RawBug) prompt just after 0x11D8 instead.

The operating system boot sequence begins at 0x11E0 with the

creation of residual data and continues to 0x11EC just before

execution is passed to the boot image. The OS may have its own

LED codes which are displayed after 0x11EC.

A line feed can be inserted after each serial code is displayed to

prevent it from being overwritten by the next code. This is also

enabled by an ENV parameter:

Serial Startup Code LF Enable [Y/N]=N?

The following firmware codes are always sent to 7-segment LEDs

located at ISA I/O address 0x8C0. These codes can also be sent to

the debugger serial port if the ENV parameter “Serial Startup Code

Master Enable” is set to ‘Y’. The list of LED/serial codes follows.

Table 1-1. LED/Serial Startup Diagnostic Codes