GEMARK* VIE CONTROL PRODUCT DESCRIPTION

INTRODUCTION

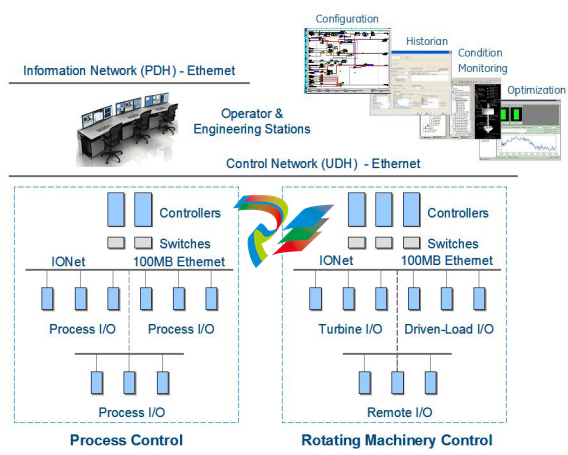

The Mark* VIe control system is a flexible platform used in multiple applications. It features

high-speed, networked input/output (I/O) for simplex, dual, and triple redundant systems.

Industry-standard Ethernet communications are used for I/O, controllers, and supervisory

interface to operator and maintenance stations, as well as third-party systems. The

ControlST* software suite, which contains the ToolboxST* toolset, is used with Mark VIe

controls and related systems for programming, configuration, trending, and analyzing

diagnostics. It provides quality, time-coherent data in the controllers and at the plant level for

effectively managing control system equipment. The Mark VIeS Safety control is a stand-alone

safety control system for safety-critical applications that conform to IEC®-61508. It also uses

the ControlST software suite to simplify maintenance, but retains a unique set of certified

hardware and software blocks. The ToolboxST application provides a means to lock or unlock

the Mark VIeS for configuration and safety instrumented function (SIF) programming.

SYSTEM OVERVIEW

A single-board controller is the heart of the system. The controller includes

the main processor and redundant Ethernet drivers to communicate with

networked I/O, and additional Ethernet drivers for the control network. A

real-time, multi-tasking operating system is used for the main processor

and I/O modules. Control software is provided in a configurable control

block language and stored in non-volatile memory. It is similar to IEEE® 854

32-bit floating-point format, and Sequential Function Charts (SFC) are also

available for complex sequencing.

The I/O network (IONet) is a dedicated, full-duplex, point-to-point

protocol. It provides a deterministic, high-speed 100 MB communications

network that is suitable for local or distributed I/O devices, and provides

communication between the main controllers(s) and networked I/O

modules. Online controllers continuously read input data directly

from the IONet, which is available in single, dual, and triple redundant

configurations. Both copper and fiber interfaces are supported.

The Mark VIe I/O modules consist of three basic parts: the terminal board,

the terminal block, and an I/O pack. Barrier or box-type terminal blocks are

mounted on a terminal board, which mounts on a DIN rail or base in the

control cabinet. The I/O pack contains two Ethernet ports, a power supply,

a local processor, and a data acquisition board. I/O capability grows as I/O

packs are added to the control system, enabling use in a simplex, dual, or

triple redundant configuration. Some process sub-systems require even

more throughput; therefore, the local processors in each I/O pack run

algorithms at higher rates as required for the application.

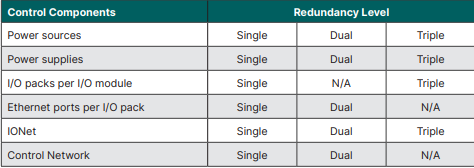

REDUNDANCY

Every application has different requirements for redundancy depending on

the criticality of the process. The Mark VIe control system provides a wide

range of redundancy options for local and remote distribution.

Dual redundant systems transmit inputs from single or redundant input

packs on dual IONets to dual Mark VIe controllers. Controllers then run

application software and transmit outputs to output packs. Three output

I/O packs may be provided to vote output signals for mission-critical field

devices. Dual redundant systems may be configured for single, dual, and

triple redundant sensors.

Triple redundant systems protect against soft or partial device failures. A

failed component is outvoted with a 2-out-of-3 logical selection (vote) or

a median value selection. Control software in all three Mark VIe controllers

runs on the voted value of the signal while diagnostics identify the failed

device. These sophisticated diagnostics reduce the mean-time-to-repair

(MTTR) while the online repair capability increases the mean-timebetween-forced-outages (MTBFO). Field sensors for these systems may

be single, dual, or triple.

I/O INTERFACE

One or multiple I/O packs are mounted on each module to digitize the

sensor signal, run algorithms, and communicate with a separate controller

containing the main processor. I/O packs have a local processor board

that runs a real-time operating system and a data acquisition board that

is unique to the specific I/O application. Local processors run algorithms

at faster speeds than the overall control system, such as the regulation of

servo valves performed within a servo module.

Each I/O processor has a local temperature sensor accurate to ±2°C (±3.6

°F). Detection of an excessive temperature generates a diagnostic alarm

and the logic is available in the database (signal space) to facilitate control

action or unique process alarm messages. The temperature is continuously

available in the database. I/O module features include:

• Dual 100 MB Ethernet ports

• 100 MB full-duplex ports

• Online repair per I/O pack

• Automatic reconfiguration

• Accuracy is specified over full operating temperature

• Internal temperature sensor

• LEDs:

- Power status and attention

- Ethernet link-connected and

communication-active

- Application-specific

• 28 V dc power

• Internal solid-state circuit breaker and soft start

A power supply provides a regulated 28 V dc power feed to each I/O pack.

The negative side of the 28 V dc is grounded through the I/O pack metal

enclosure and its mounting base. The positive side has solid-state circuit

protection built into the I/O pack with a nominal 2 A trip point. Online repair

is possible by removing the 28 V dc connector, replacing the I/O pack, and

re-inserting the power connector. I/O packs are automatically reconfigured

if the Auto-Reconfiguration feature is enabled.

TERMINAL BLOCKS

Signal flow begins with a sensor connected to a terminal block on an I/O

module. The terminal board mounts to the cabinet and is available in two

basic types: T-type and S-type modules.

T-type modules typically fan the inputs to three separate I/O packs.

They contain two removable 24-point, barrier-type terminal blocks. Each

point can accept two 3.0 mm2 (#12,AWG) wires with 300 V insulation per

point and spade or ring-type lugs. Captive clamps are also provided for

terminating bare wires. Screw spacing is 9.53 mm (0.375 in) minimum,

center-to-center. T-type modules are normally surface mounted, but may

also be DIN-rail mounted.

A shield strip is provided next to each block, which is actually the left-hand

side of the metal base where the module is mounted. Wide and narrow

modules are arranged in vertical columns of high and low-level wiring that

can be accessed from top and/or bottom cable entrances. An example of a

wide module is a module containing magnetic relays with fused circuits for

solenoid drivers.

Box-type and Barrier-type Terminal Blocks in Simplex and Triple Redundant Configuration

S-type modules provide a single set of screws for each I/O point and allows

a single I/O pack to condition and digitize the signal. This board is used

for simplex, dual, and dedicated triple modular redundant (TMR) inputs by

using one, two, or three boards. They are half the size of T-type modules

and are DIN-rail or surface mounted. Two versions of the S-type modules

are available: fixed terminal blocks and removable terminal blocks.

Fixed box-type terminal blocks accept one 3.0 mm2 (#12 AWG) wire or two

2.0 mm2 (#14 AWG) wires with 300 V insulation per point. Screw spacing is

5.08 mm (0.2 in) minimum, center-to-center. Removable box terminals may

be replaced with spring-cage-clamp, insulation displacement, or crimpand-stab terminals. A shield strip is provided on each terminal block and is

tied to functional ground.

TEMPERATURE RATINGS

Mark VIe electronics are packaged in different locations world-wide and

customized for a variety of protection classifications with and without

ventilation and cooling. Controllers, I/O modules, power supplies, etc. are

rated for -30 to 65°C (-22 to 149°F) at the electronics. To compliment the

Mark VIe Control’s native I/O modules, a variety of fieldbus solutions are

available with master communication gateways on the I/O network. These

modules have slightly reduced operating temperature ratings:

• PROFIBUS® Master Gateway: -20 to 55°C (-4 to 131°F)

• CANopen® Master Gateway: -20 to 55°C (-4 to 131°F)

• FOUNDATION Fieldbus™ Linking Device: 0 to 55°C (32 to 131°F)

Modules with reduced operating temperatures should be mounted lower

in the cabinet to avoid the natural temperature gradient from the bottom

to the top of the enclosure. Control room equipment such as operator

stations has an operating temperature range of 20 to 30°C (68 to 86°F).

For shipping and storage, the controllers, I/O modules, power supplies, etc.

are rated -40 to 85°C (-40 to 185°F), and control room equipment is rated

0 to 30°C (32 to 86°F).

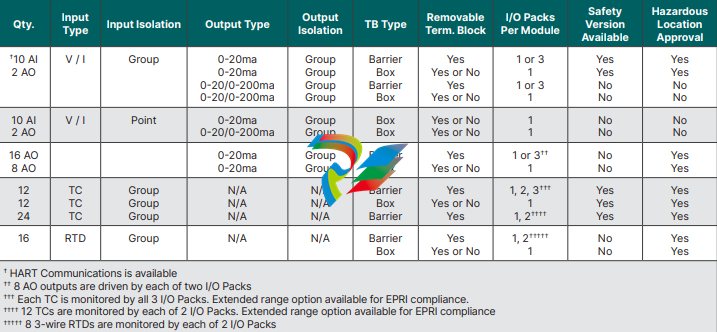

I/O MODULES

I/O modules can be categorized as generic and application-specific.

As an example, discrete inputs (contact inputs) are used in virtually all

applications and differ primarily in their voltage rating. Other considerations

in selecting a module are its redundancy, isolation (group or point), terminal

block type, availability for safety applications (IEC 61508), and approval for

hazardous locations.

A typical application-specific module is a servo module that is used for

fast closed-loop control of a turbine’s servo valve actuator or a complete

emergency over-speed trip system for a turbine. These unique modules

will not be described in the following tables. However, some applicationspecific modules such as a vibration module is commonly applied in

monitoring radial and axial shaft displacement of rotating machinery in

plant distributed control systems and will be described in a separate table.

Analog Input (AI) and Analog Output (AO) Modules

• V/I designates a voltage / current input

• TC designates thermocouples

• RTD designates resistance temperature device

Analog I/O modules typically contain 10 analog inputs and 2 analog outputs. 8 inputs can be configured for

1-5Vdc, ±5Vdc, ±10Vdc, or 0-20ma with jumpers on the module, and the remaining 2 inputs can be configured for

0-20ma or +/-1ma with 250 Ω / 5,000 Ω burden resistors respectively. For applications with a high concentration

of analog outputs, dedicated output modules are available for 0-20ma and others for 0-20ma / 0-200ma selection

for valve actuators (800 Ω / 50 Ω output loads respectively). Transducers can be externally powered (differential

inputs) or internally powered from the I/O module with +24Vdc current limited per point. I/O modules are available

with point isolation for externally powered transducers.

In general, RTDs are useful for precision temperature measurements below 800°C, and thermocouples are cost

effective devices for monitoring a wider temperature range. RTD modules provide a 10 ma multiplexed excitation

current to each RTD, which can be grounded or ungrounded. They support 100 and 200 Ω platinum, 10 Ω copper,

and 120 Ω nickel 3-wire RTDs with software linearization per point. The linearization includes scaling for specific

RTD standards such as a MINCO-CA or CU10 10 Ω copper RTDs. RTDs can be located up to 300 meters (984

feet) from the I/O module with a maximum two-way cable resistance of 15 Ω.