WATLOWMLS300 Series User’s Guide

Manual Contents

This manual describes how to install, setup, and operate a

MLS316 or MLS332 controller. Each chapter covers a

different aspect of your control system and may apply to

different users. The following describes each chapter’s

purpose.

• Chapter 1: System Overview. Provides a component list

and summary of features for the MLS300 controllers.

• Chapter 2: Installation. Provides detailed instructions

on installing the MLS300 controller and its peripherals.

• Chapter 3: Using the MLS300. Provides an overview of

operator displays used for system monitoring and job

selection.

• Chapter 4: Setup. Provides detailed descriptions of all

menus and menu options for controller setup.

• Chapter 5: Extruder Options. Explains the additional

features on an MLS300 controller equipped with Extruder

Control Firmware.

• Chapter 6: Enhanced Features. Describes process

variable retransmit, ratio, differential and cascade control

features available with the enhanced features option.

• Chapter 7: Ramp/Soak. Explains how to setup and use

the features of the ramp/soak option.

• Chapter 8: Tuning and Control. Describes available

control algorithms and provides suggestions for

applications.

• Chapter 9: Troubleshooting and Reconfiguring.

Includes troubleshooting, upgrading and reconfiguring

procedures for technical personnel.

• Chapter 10: Linear Scaling Examples. Provides an

example configuring a pressure sensor, a flow sensor, and

an encoder using linear scaling.

• Chapter 11: Specifications. Lists detailed specifications

of the controller and optional components.

Getting Started

The following sections provide information regarding product

features, technical descriptions, safety requirements, and

preparation for operation.

These symbols are used throughout this manual:

DANGER! Indicates potential for serious injury or loss

of human life.

WARNING! Indicates possible damage to property or

equipment.

NOTE! Indicates pertinent information in order to

proceed.

Initial Inspection

Accessories may or may not be shipped in the same container

as the MLS300, depending upon their size. Check the

shipping invoice carefully against the contents received in all

boxes.

Product Features

The MLS300 series controllers provide 16 or 32 fully

independent loops of PID control. When used as a stand-alone

controller, you may operate the MLS300 via the two-line 16-

character display and touch keypad. You can also use it as the

key element in a computer-supervised data acquisition and

control system; the MLS300 can be locally or remotely

controlled via an EIA/RS-232 or EIA/RS-485 serial

communications interface.

The MLS300 features include:

• Direct Connection of Mixed Thermocouple Sensors:

Connect most thermocouples to the controller with no

hardware modifications. Thermocouple inputs feature

reference junction compensation, linearization, process

variable offset calibration to correct for sensor

inaccuracies, detection of broken, shorted or reversed

thermocouples, and a choice of Fahrenheit or Celsius

display.

• CIM300 Input Option: The CIM300 input module

provides high density sensor termination with a smaller

installation footprint and faster installation.

• Accepts Resistive Temperature Detectors (RTDs): Use

3-wire, 100 ohm, platinum, DIN-curve sensors with two

choices for range and precision of measurements. (To use

this input, order a MLS316 or MLS332 controller with

scaling resistors.)

• Automatic Scaling for Linear Analog Inputs: The

MLS300 series automatically scales linear inputs used

with other industrial process sensors. Enter two points,

and all input values are automatically scaled in your units.

Scaling resistors must be installed.

• Dual Outputs: The MLS300 series includes both heat

and cool outputs for up to 16 loops. Independent control

parameters are provided for each output.

• Independently Selectable Control and Output Modes:

You can set each control output to ON/OFF, Time

Proportioning, Serial DAC, or Distributed Zero Crossing

mode. Set up to two outputs per loop for ON/OFF, P, PI,

or PID control with reverse or direct action.

• Control Outputs: Set high/low deviation and high/low

process limits to operate digital outputs as on/off control

functions or alarms.

• Flexible Alarm Outputs: Independently set high/low

process alarms and a high/low deviation band alarm for

each loop. Alarms can activate a digital output by

themselves, or they can be grouped with other alarms to

activate an output.

• Global Alarm Output: When any alarm is triggered, the

Global Alarm Output is also triggered, and it stays on until

you acknowledge it.

• CPU Watchdog: The MLS300 series CPU watchdog

timer output notifies you of system failure. You can use it

to hold a relay closed while the controller is running, so

you are notified if the microprocessor shuts down.

• Front Panel or Computer Operation: Set up and run the

controller from the front panel or from a local or remote

computer. WatView software is available to configure

and monitor the MLS300 from a PC.

• Modbus RTU Protocol, EIA/TIA-232 and 485

Communications: Connect to PLCs, operator interface

terminals and third-party software packages using the

widely supported Modbus RTU protocol.

• Multiple Job Storage: Store up to 8 jobs in memory, and

access them locally by entering a single job number or

remotely via digital inputs. Each job is a set of operating

conditions, including set points and alarms.

• Non-Linear Output Curves: Select either of two nonlinear output curves for each control output.

• Autotuning Makes Setup Simple: Use the Autotune

feature to set up your system quickly and easily. The

MLS300 internal expert system table finds the correct

PID parameters for your process.

• Pulse Counter Input: Use the pulse counter input for

precise control of motor or belt speed.

• Low Power Shutdown: The controller shuts down and

turns off all outputs when it detects the input voltage drop

below the minimum safe operating level.

MLS300 Series User’s Guide Chapter 1: System Overview

Doc.# 0600-3070-2000 Watlow Anafaze 5

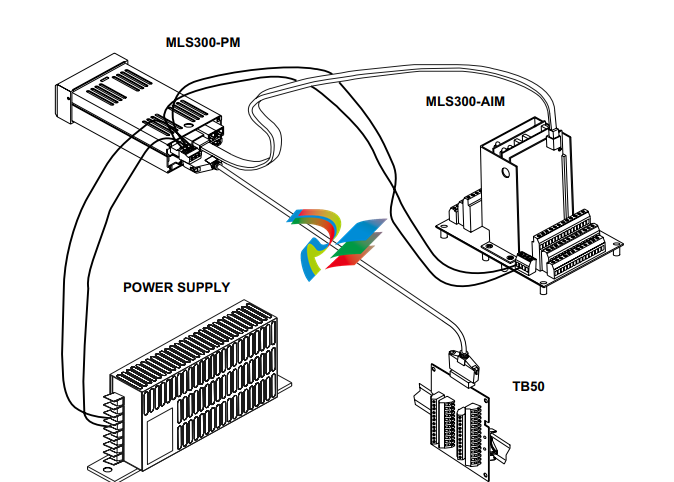

System Diagram

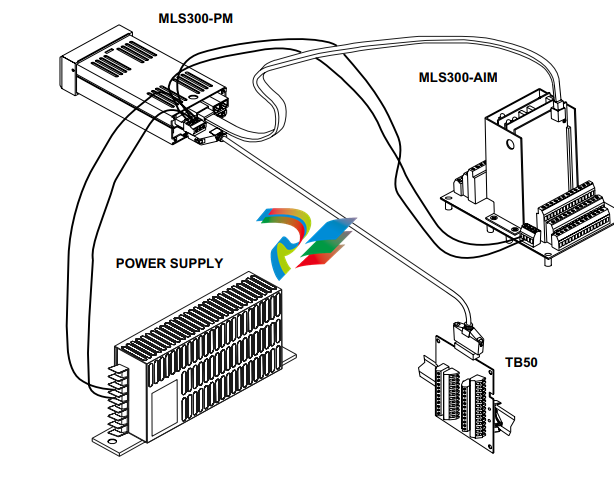

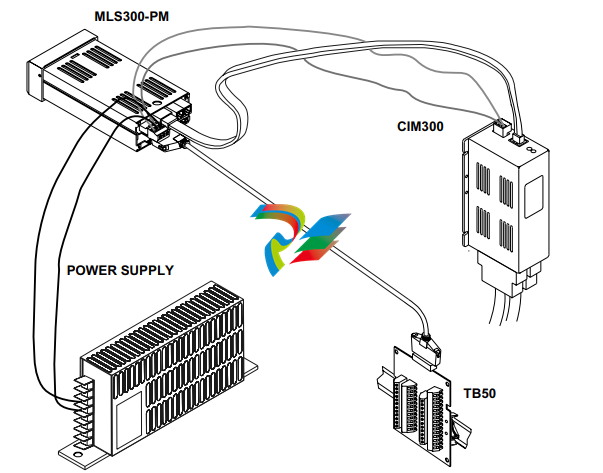

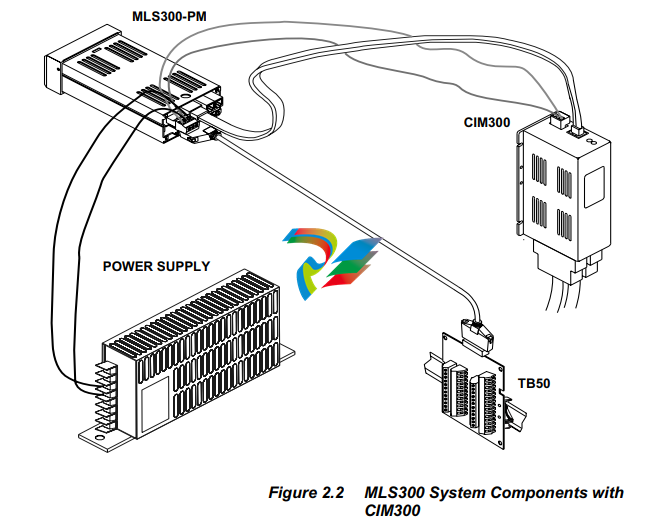

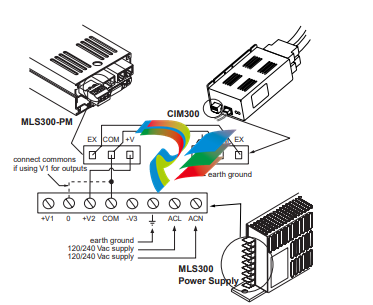

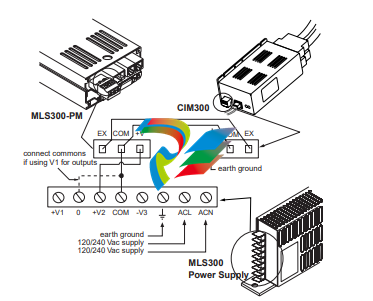

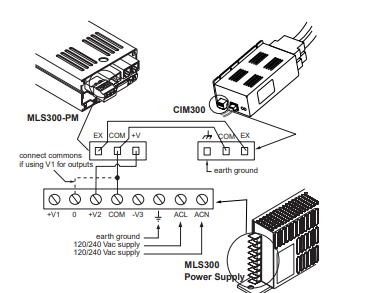

The illustration below shows how the parts of the MLS300 are

connected. When unpacking your system, use the diagram and

parts list below to ensure all parts have been shipped. Please

don't hesitate to call Watlow Anafaze's Customer Service

Department if you have problems with your shipment, or if the

MLS300's components are missing or damaged.

Parts List MLS316/MLS332

You may have received one or more of the following

components. Refer to Figure 1.1 on page 5 and Figure 1.2 on

page 6 for MLS300 configuration information.

• MLS300 Processor Module (PM)

• Controller Mounting Kit

• 16- or 32-Channel MLS300-AIM Module with 4-foot

AIM cable

• 16- or 32-Channel CIM300 Module with 4-foot AIM

cable.

• EIA/RS-232 or EIA/RS-485 Communication Cable

• TB50 with 50-pin SCSI Cable

• Power Supply with Mounting Bracket and Screws

• SDAC (Serial Digital-to-Analog Converter)

• Special Input Resistors (installed in MLS300 AIM)

• User Manual

Technical Description

This section contains a technical description of each

component of your MLS300 Controller.

Processor Module

The MLS300 Processor Module (MLS300-PM) is housed in

an eighth-DIN panel mount package. It contains the CPU,

RAM with a built-in battery, EPROM, serial communications,

digital I/O, the screen and touch keypad.

The MLS300-PM has the following features:

• Keypad and 2-line, 16-character display.

• Screw terminals for the power inputs and outputs.

• Input power is 12 to 24 Vdc at 1 amp.

• The +5 Vdc output power supply of the processor module

powers the MLS300-AIM.

• The MLS300-PM interfaces with the MLS300-AIM with

an 8-pin RJ-45 style connector.

• A 50-pin SCSI cable connects the digital inputs and

outputs to the 50-pin terminal block (TB50).

• The MLS300 uses 6-pin, telephone-style connectors for

EIA/RS-232 and EIA/RS-485 external communications.

The program that operates the MLS300 is stored in a socketed,

flash, static-RAM chip, so it is easy to update or change the

firmware. The MLS300 stores its operating parameters in

battery-backed RAM, so if there's a power loss the operating

parameters are unchanged. The battery has a ten year shelf

life, and it is not used when the unit is on.

The microprocessor performs all calculations for input signal

linearization, PID control, alarms, and communications.

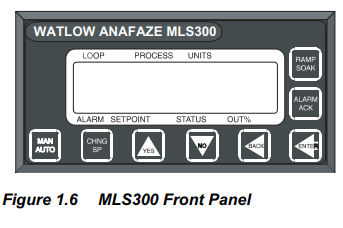

Front Panel Description

The MLS300-PM's display and touch keypad provide an

intelligent way to operate the MLS300. The display has 16

alphanumeric or graphic characters per line. The 8-key

keypad allows you to change the MLS300's operating

parameters, controller functions, and displays.

The MLS300's information-packed displays show process

variables, set points, and output levels for each loop. A bar

graph display, single loop display, scanning display and an

alarm display offer a real-time view of process conditions.

Two access levels allow operator changes and supervisor

changes.

The TB50 is a screw terminal interface for control wiring

which allows you to connect relays, encoders and discrete I/O

devices to the MLS300. The screw terminal blocks accept

wires as large as 18 AWG. A 50-pin SCSI cable connects the

TB50 to the MLS300-PM

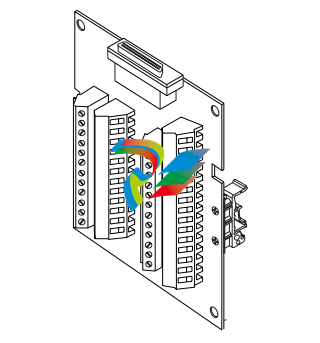

MLS300-AIM and AIM-TB

The MLS300 Analog Input Module (MLS300-AIM), consists

of the AIM-TB (AIM Terminal Board) and the AIM’s plug-in

cards. The MLS300-AIM receives input signals from sensors

and transmits this information to the MLS300-PM through the

AIM cable.

The AIM-TB includes power supply terminals, input signal

wiring screw terminals, input signal conditioning circuits, and

terminal connections for the AIM's plug-in cards. It also

includes a cold junction temperature sensor and room for the

input scaling resistors, if required. (RTDs, inputs greater than

60 mVdc, and mAdc current inputs require input scaling

resistors.) The AIM-TB has three slots for the plug-in AIM

cards.

There are two versions of the MLS300-AIM: the AIM-16 and

AIM-32. The AIM-16 has one multiplexer (MUX) card, and

the AIM-32 has two MUX cards. These cards multiplex the 16

inputs each card receives. Each -10 to 60 mVdc input is

converted to a voltage that is transmitted to the Voltage/

Frequency (V/F) card. (The MUX cards also automatically

calibrate the zero and span of the analog amplifier and

measure the cold junction compensation temperature for

thermocouple inputs.) Both the AIM-16 and AIM-32 have a

V/F card, which converts the input signal voltage to a

frequency. The converted signal is then transmitted via the

AIM cable to the MLS300-PM for processing.

The MLS300 Compact Input Module (CIM300) consists of

two circuit boards that perform analog-to-digital conversion

and data communications to the processor module. The

CIM300 receives input signals from sensors and transmits this

information to the MLS300-PM through the AIM cable.

The CIM300 includes power supply terminals, input signal

connectors, a communications connector and input signal

conditioning circuits. It also includes a cold-junction

temperature sensor and room for the input scaling resistors, if

required. (RTDs, inputs greater than 60 mV dc, and mA dc

current inputs require input scaling resistors.)

There are two versions of the CIM300: the CIM316 and

CIM332. The CIM316 supports 16 inputs through a D-Sub 50

female connector and the CIM332 supports 32 inputs through

2 D-Sub 50 connectors (inputs 1 to 16 female, inputs 17 to 32

male). The user supplies the mating D-Sub 50 connectors. The

CIM300 has one or two multiplexer circuits that multiplex the

16 inputs each card receives. Each -10 to 60 mV dc input is

converted to a voltage that is transmitted to the Voltage/

Frequency (V/F) card. (The mulitplexer circuits also

automatically calibrate the zero and span of the analog

amplifier and measure the cold-junction compensation

temperature for thermocouple (T/C) inputs.) A V/F circuit

converts the input signal voltage to a frequency. The

converted signal is then transmitted via the AIM cable to the

MLS300-PM for processing

MLS300 Cabling

Watlow Anafaze provides cables required to install your

MLS300.

A 50-pin SCSI cable connects the TB50 to the MLS300-PM.

The cable connecting the MLS300-PM to the AIM-TB is an

8-conductor, shielded cable with RJ-45 connectors.

The cables used to connect the MLS300 to EIA/RS-232 or

EIA/RS-485 communications are 6-conductor, shielded cable

with RJ-12 connectors on one end and a DB-9 connector or

bare wires on the other end.

The pin numbering convention used for communications cables varies between suppliers. See Serial Communications, Cable

Connector Pin Outs on page 62.

Safety

Watlow Anafaze has made every effort to ensure the

reliability and safety of this product. In addition, we have

provided recommendations that will allow you to safely

install and maintain this controller.

Ensure that power has been shut off to your

entire process before you begin installation

of the controller.

WARNING! In any application, failures can occur. These

failures can result in full control output (100%

power), or the occurrence of other output failures which can cause damage to the controller, or to the equipment or process

connected to the controller. Therefore, always follow good engineering practices,

electrical codes, and insurance regulations

when installing and operating this equipment.

External Safety Devices

External safety devices should be used to prevent potentially

dangerous and unsafe conditions upon equipment failure.

Always assume that this device can fail with outputs full-on,

or full-off, by the occurrence of an unexpected external

condition.

Always install high or low temperature protection in installations where an over-temperature or under-temperature fault will present

a potential hazard. Failure to install external

protection devices where hazards exist can

result in damage to equipment and property

as well as loss of human life.

Power-Fail Protection

In the occurrence of a sudden loss of power, this controller can

be programmed to reset the control outputs to OFF (this is the

default). Typically, when power is re-started, the controller

restarts to data stored in memory. If you have programmed the

controller to restart with control outputs ON, the memorybased restart might create an unsafe process condition for

some installations. Therefore, you should only set the restart

with outputs ON if you are certain your system will safely

restart. (See Process Power Digital Input on page 98).

When using a computer or host device, you can program the

software to automatically reload desired operating constants

or process values on power-up. Keep in mind that these

convenience features do not eliminate the need for

independent safety devices.

Contact Watlow Anafaze immediately if you have any

questions about system safety or system operation.

This chapter describes how to install the MLS300 series

controller and its peripherals. Installation of the controller

involves the following procedures:

• Determining the best location for the controller

• Mounting the controller, the AIM and the TB50

• Power connection

• Testing the system

• Input wiring

• Output wiring

• Communications wiring (EIA/TIA-232 or EIA/TIA485)

Typical Installation

Figure 2.1 on page 18 illustrates a typical installation of the

MLS300-PM (controller) with the MLS300-AIM (analog

input module), TB50 terminal block, and power supply.

Refer to Figure 2.15 on page 36 for a more detailed view of

the power connections.

Read this entire chapter before beginning the installation

procedure.

Mounting Controller Components

Install the controller in a location free from excessive heat

(more than 50°C), dust and unauthorized handling.

Electromagnetic and radio frequency interference can induce

noise on sensor wiring. Select locations for the MLS300-PM

and MLS300-AIM and CIM300 such that wiring can be

routed clear of sources of interference such as high voltage

wires, power switching devices and motors

! The MLS300 system is for indoor use only. Install it in a controlled environment to reduce

the risk of fire or electric shock.

Recommended Tools

Use these tools to install the MLS300 series controller.

Panel Hole Cutters

Use any of the following tools to cut a hole of the appropriate

size in the panel.

• Jigsaw and metal file, for stainless steel and heavyweight

panel doors.

• Greenlee 1/8 DIN rectangular punch (Greenlee part #

600-68), for most panel materials and thicknesses.

• Nibbler and metal file, for aluminum and lightweight

panel doors.

Other Tools

You will also need these tools:

• Phillips head screwdriver

• Flathead screwdriver for wiring

• Multimeter

• A metal phone connector crimping tool (optional).

Watlow Anafaze provides all the cabling for the Modular

Loop System. If you have special cabling requirements and

you make your own RJ-12 communications cable, use a metal

crimping tool for the connectors. (A metal tool makes better

connections than a plastic tool.)

Mounting the Processor Module

Mount the processor module before you mount the terminal

block or do any wiring. The controller's placement affects

placement and wiring considerations for the other

components of your system.

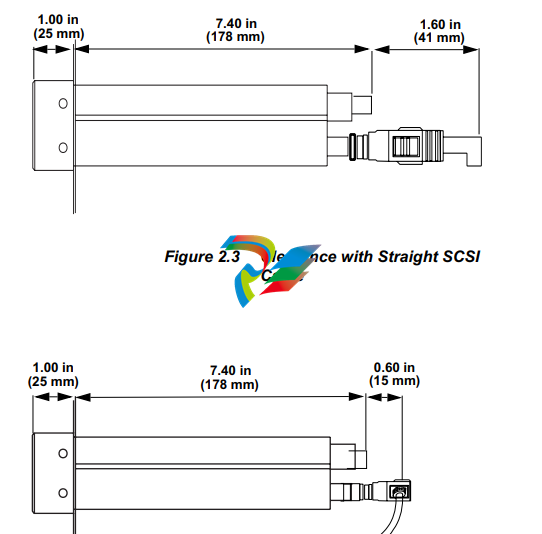

Ensure there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections; the

controller extends up to 9.0 in. (219 mm) behind the panel

face and the collar and brackets extend 9/32 in. (7 mm) on the

sides and 15/32 in. (12 mm) above and below it.

We recommend you mount the controller in a panel not more

than 0.2 in. (5 mm) thick.

1. Choose a panel location free from excessive heat (more

than 50°C), dust, and unauthorized handling. (Make sure

there is adequate clearance for the mounting hardware,

terminal blocks, and cables. The controller extends 7.40

in. (178 mm) behind the panel. Allow for an additional

0.60 to 1.60 in. (15 to 41 mm) beyond the connectors.

2. Temporarily cover any slots in the metal housing so that

dirt, metal filings, and pieces of wire do not enter the

housing and lodge in the electronics.

3. Cut a hole in the panel 1.80 in. (46 mm) by 3.63 in. (92

mm) as shown below. (This picture is NOT a template; it

is for illustration only.) Use caution; the dimensions given here have 0.02 in. (1 mm) tolerances.

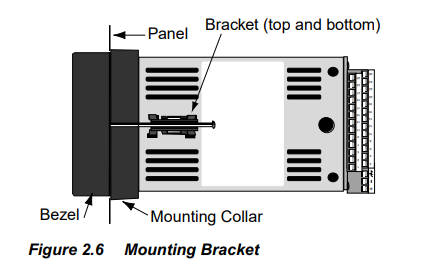

4. Remove the brackets and collar from the processor module, if they are already in place.

5. Slide the processor module into the panel cutout.

Slide the mounting collar over the back of the processor

module, making sure the mounting screw indentations

face toward the back of the processor module.

Loosen the mounting bracket screws enough to allow for

the mounting collar and panel thickness. Place each

mounting bracket into the mounting slots (head of the

screw facing the back of the processor module). Push

each bracket backward then to the side to secure it to the

processor module case.

Make sure the case is seated properly. Tighten the installation

screws firmly against the mounting collar to secure the unit.

Ensure that the end of the mounting screws fit into the

indentations on the mounting collar.

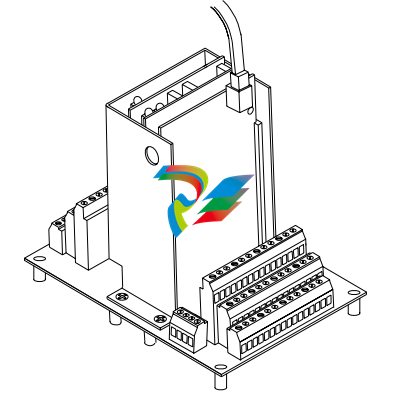

Mounting the MLS300-AIM

!

NOTE! If you plan to install scaling resistors, mount

them on the AIM-TB before mounting the

AIM-TB in the panel. See Chapter 9, Troubleshooting and Reconfiguring.

If you ordered an MLS300-AIM-TB with scaling inputs from Watlow Anafaze, the scaling

resistors are already installed.

Install the MLS300-AIM in a location free from excessive

(more than 50°C) heat, dust, and unauthorized handling.

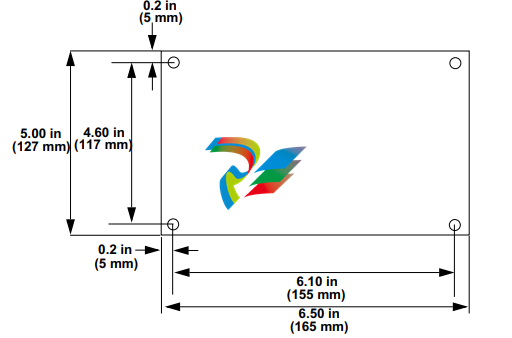

The MLS300-AIM measures 6.5 L x 5 W x 7 in. H. Leave 6

in. of clearance above the MLS300-AIM, so you can remove

the entire unit (or just the AIM cards) if necessary.

1. Choose an appropriate place to install the MLS300-AIM.

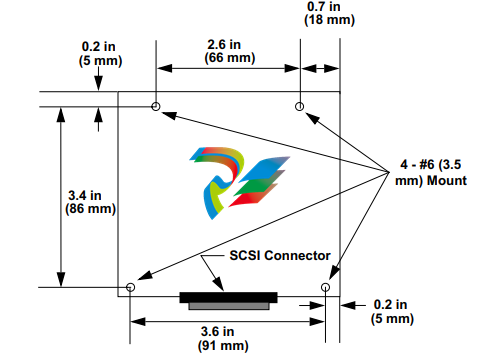

2. Use the template shown in Figure 2.7 as a reference for

clearance and dimensions.

Figure 2.7 MLS300-AIM Template

3. Drill four holes for #6 or #8 screws in the chosen

location.

4. Place the MLS300-AIM where you will mount it. Use

screws with internal star lock washers to ensure a good

Frame Ground connection. You may use self-tapping

screws. Insert the screws through the standoffs and

tighten them.

5. Be sure to remove any loose metal filings after you are

finished mounting the MLS300-AIM.

Mounting the CIM300

!

NOTE! If you plan to install scaling resistors, mount

them on the CIM300 before mounting the

CIM300 in the panel. See Chapter 9, Troubleshooting and Reconfiguring.

If you ordered a CIM300 with scaling inputs from Watlow

Anafaze, the scaling resistors are already installed.

Install the CIM300 in a location free from excessive (more

than 50ºC) heat, dust and unauthorized handling. The CIM300

measures 7.5 L x 2.75 W x 3.75 inches D. Leave 1.5 inches of

clearance above the CIM300, so that there will be enough

space for power and communications wires.

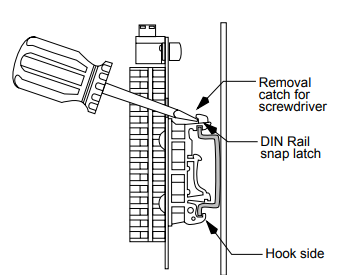

DIN Mounting

1. Choose an appropriate place to install the CIM300.

2. Snap the CIM300 on to the DIN rail by placing the hook

side on the rail first, then pushing the snap latch side in place.

(To remove the CIM300 from the rail, use a flat-head screw

driver to unsnap the bracket from the rail.)

Direct Mounting

1. Choose an appropriate place to install the CIM300.

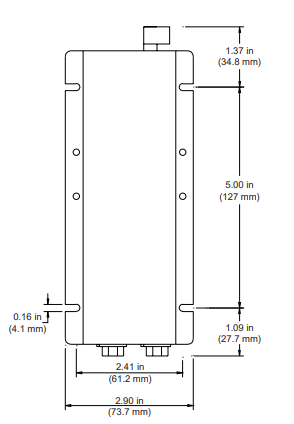

2. Use the dimensions shown in Figure 2.8 as a reference for

clearance and dimensions

Figure 2.8 CIM300 Template

3. Drill four holes for #6 or #8 screws in the chosen location.

4. Place the CIM300 where you will mount it. Use screws with

internal star lock washers to ensure a good frame ground

connection. You may use self-tapping screws. Insert the

screws through the standoffs and tighten them.

5. Be sure to remove any loose metal filings after you are

finished mounting the CIM300.

Do not connect power or sensors to the

MLS300 now. Test the unit first, as explained

in the Power Wiring and Controller Test section.

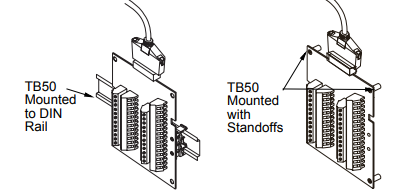

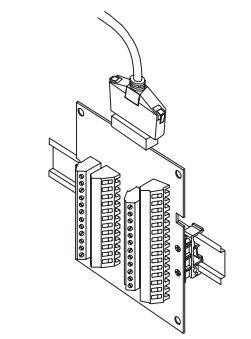

Mounting the TB50

There are two ways you can mount the TB50: use the preinstalled DIN rail mounting brackets provided or use the

plastic standoffs. Follow the corresponding procedures to

mount the board

DIN Rail Mounting

Snap the TB50 on to the DIN rail by placing the hook side on

the rail first, then pushing the snap latch side in place. Refer

to Figure 2.10.

Figure 2.10 TB50 Mounted on a DIN Rail (Front)

To remove the TB50 from the rail, use a flat-head screw driver

to unsnap the bracket from the rail. See Figure 2.11

Figure 2.11 TB50 Mounted on DIN Rail (Side)

Mounting with Standoffs

1. Remove the DIN rail mounting brackets from the TB50.

2. Select a location with enough clearance to remove the

TB50, its SCSI cable, and the controller itself.

3. Mark the four mounting holes.

4. Drill and tap the 4, #6 (3.5 mm) mounting holes.

5. Mount the TB50 with 4 screws.

There are four smaller holes on the terminal board. Use these

holes to secure wiring to the terminal block with tie wraps.

Figure 2.12 Mounting a TB50 with Standoffs

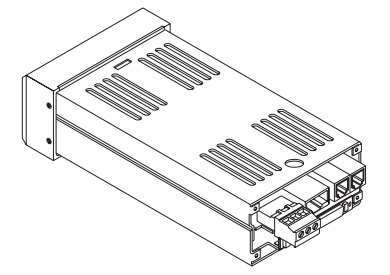

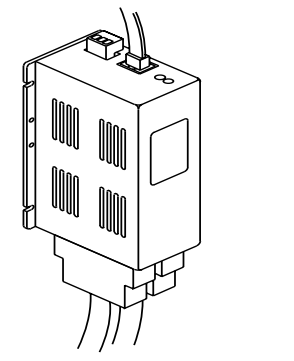

Mounting the Power Supply

If you use your own power supply for the MLS300, please

refer to the power supply manufacturer's instructions for

mounting information. Choose a power supply that supplies

an isolated regulated 12 to 24 Vdc at 1 A.

Mounting Environment

Leave enough clearance around the power supply so that it

can be removed.

Mounting DAC or SDAC Module

This section describes how to install the optional DAC and

SDAC Digital-to-Analog Converters for use with a MLS300

series controller.

Installation

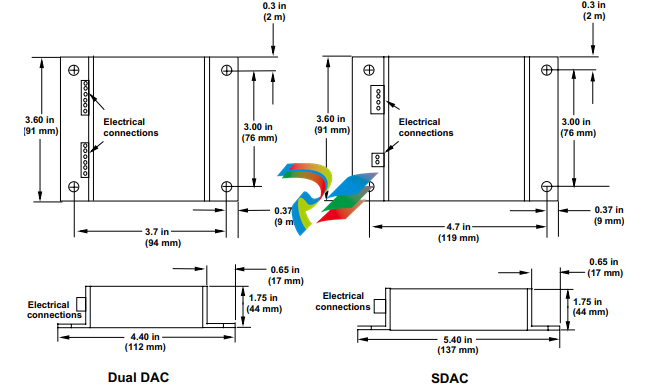

Installation of the DAC and SDAC is essentially the same.

The main differences are in the dimensions and the wiring.

Follow this procedure to correctly install these devices.

Jumpers

The output signal range of the DAC and SDAC modules is

configured with jumpers. See Configuring DAC Outputs on

page 210 and Configuring SDAC Outputs on page 212 for

information on setting these jumpers.

Mounting

1. Select a location for installation. The unit is designed for

wall mounting and should be installed as close to the controller as possible.

2. Mark and drill four holes for screw mounting. Holes

accommodate #6 size screws. Use the diagrams in Figure

2.14 on page 32 for the correct locations.

3. Install the unit with the four screws.

Figure 2.14 Dual DAC and SDAC Dimensions

System Wiring

Successful installation and operation of the control system can

depend on placement of the components and on selection of

the proper cables, sensors, and peripheral components.

Routing and shielding of sensor wires and proper grounding

of components can insure a robust control system. This

section includes wiring recommendations, instructions for

proper grounding and noise suppression, and considerations

for avoiding ground loops.

Never wire bundles of low power Watlow

Anafaze circuits next to bundles of high power ac wiring. Instead, physically separate

high power circuits from the controller. If

possible, install high voltage ac power circuits in a separate panel.

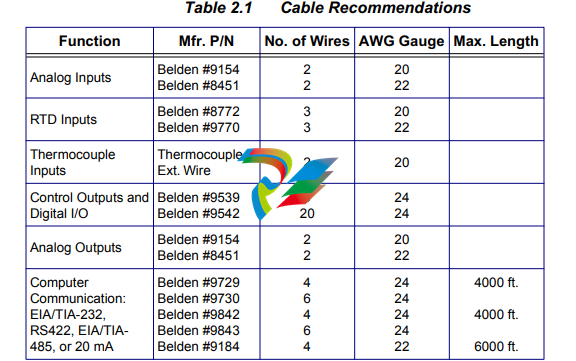

Wiring Recommendations

Keep the following guidelines in mind when selecting wires

and cables:

• Use stranded wire. (Solid wire can be used for fixed

service; it makes intermittent connections when you

move it for maintenance.)

• Use #20 AWG thermocouple extension wire. Larger or

smaller sizes may be difficult to install, may break easily,

or may cause intermittent connections.

• Use shielded wire. (The electrical shield protects the

signals and the MLS300 from electrical noise.) Connect

one end of the input and output wiring shield to earth

ground.

• Use copper wire for all connections other than

thermocouple sensor inputs.

See Table 2.1 on page 33 for cable recommendations.

Noise Suppression

The MLS300’s outputs are typically used to drive solid state

relays. These relays may in turn operate more inductive types

of loads such as electromechanical relays, alarm horns and

motor starters. Such devices may generate electromagnetic

interference (EMI or noise). If the controller is placed close to

sources of EMI, it may not function correctly. Below are some

tips on how to recognize and avoid problems with EMI.

For the AIM or CIM300 earth ground wire, use a large gauge

and keep the length as short as possible. Additional shielding

may be achieved by connecting a chassis ground strap from

the panel to the case of the processor module.

Symptoms of RFI/EMI

If your controller displays the following symptoms, suspect

EMI:

• The controller's display blanks out and then re-energizes

as if power had been turned off for a moment.

• The process variable does not display correctly.

EMI may also damage the digital output circuit—so digital

outputs will not turn on. If the digital output circuit is

damaged, return the controller to Watlow Anafaze for repair.

Avoiding Noise Problems

To avoid RFI/EMI noise problems:

• The MLS300 system includes noise suppression

circuitry. Some of which is only effective when the

components are properly grounded. Be sure the

processor module and AIM (or CIM300) are connected

to earth ground.

• Separate the 120 or 240 Vac power leads from the low

level input and output leads connected to the MLS300

series controller. Don't run the digital I/O or control

output leads in bundles with 120 Vac wires.

• Where possible, use solid-state relays (SSRs) instead of

electromechanical (EM) relays. If you must use EM

relays, try to avoid mounting them in the same panel as

the MLS300 series equipment.

• If you must use EM relays and you must place them in a

panel with MLS300 series equipment, use a 0.01

microfarad capacitor rated at 1000 Vac (or higher) in

series with a 47 Ω, 1/2 watt resistor across the NO

contacts of the relay load. This is known as a snubber

network and can reduce the amount of electrical noise.

• You can use other voltage suppression devices, but they

are not usually required. For instance, you can place a

metal oxide varistor (MOV) rated at 130 Vac for 120 Vac

control circuits across the load, which limits the peak AC

voltage to about 180 Vac (Watlow Anafaze P/N 0802-

0826-0000). You can also place a transorb (back to back

zener diodes) across the digital output, which limits the

digital output voltage.

The above steps will eliminate most EMI/RFI noise problems.

If you have further problems or questions, please contact

Application Engineering

Avoiding Ground Loops

Ground loops occur when current passes from the process

through the controller to ground. This can cause instrument

errors or malfunctions.

A ground loop may follow one of these paths, among others:

• From one sensor to another.

• From a sensor to the communications port.

• From a sensor to the dc power supply.

The best way to avoid ground loops is to minimize

unnecessary connections to ground. Do not connect any of the

following terminals to each other or to earth ground:

• MLS300 PM: TB1, pin 2 (COM)

• MLS300-AIM: TB3, pin 1 to (PWR COM)

• All A COM terminals on the MLS300-AIM or CIM300

• Power Supply: (COM)

• Pin 3 on the RJ connector

Watlow Anafaze strongly recommends that you:

• Isolate outputs through solid state relays, where possible.

• Isolate RTDs or “bridge” type inputs from ground.

• Isolate digital inputs from ground through solid state

relays. If you can't do that, then make sure the digital

input is the only place that one of the above pins connects

to earth ground.

• If you are using EIA/TIA-232 from an un-isolated host,

don't connect any other power common point to earth

ground, or use an optical isolator in the communications

line.

Personal Computers and Ground Loops

Many PC communications ports connect the communications

common to chassis ground. When such a PC is connected to

the controller, this can provide a path to ground for current

from the process that can enter the controller through a sensor

(such as a thermocouple). This creates a ground loop that can

affect communications and other controller functions. To

eliminate a ground loop, either use an optically isolated

communications adapter or take measures to ensure that

sensors and all other connections to the controller are isolated

and not conducting current into the unit.

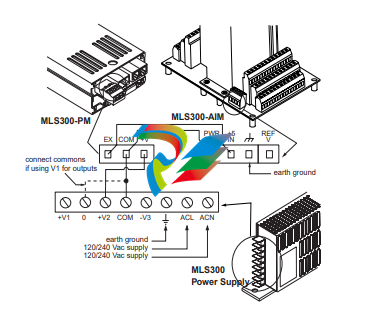

Power Connections

This section covers making the power connections between

the MLS300 components and testing those connections before

completing sensor and controller wiring in the following

sections.

Figure 2.15 on page 36 and Figure 2.16 on page 36 illustrates

the power connections.

Figure 2.15 Power Connections with MLS300-

AIM

Figure 2.16 Power Connections with CIM300

At this point you have isolated the parts of

the MLS300 that can be damaged by excess

voltage.

4. With ac power on, use a voltmeter to measure the

following:

(a) The voltage between the COM and +V terminals

on TB 1 should be +12 to 24 Vdc

(b) The voltage between COM and EX should be 0

Vdc

5. If the voltages are not as described in Step 4, check the

installation of the power supply, troubleshoot or replace

the power supply. If the voltages are within the limits

described in Step 4, continue to Step 6.

6. Turn off the power and plug TB1 back into the MLS300-

PM.

7. Turn the power back on. The Processor Module's display

should light up, and after about a second the Bar Graph

display should appear, followed by the message AIM

COMM FAIL.

8. Verify power to the MLS300-AIM. With a voltmeter,

measure the following:

(a) The voltage between +5 IN and PWR COM terminals on TB-3 on the MLS300-AIM should be

+4.75 to +5.25 Vdc.

9. If the voltage is not as described in Step 8, check the

wiring from the MLS300-PM to the MLS300-AIM. If

the voltage is within the limit described in Step 8,

continue to Step 10.

10. Turn off the power and carefully insert the AIM cards

back into the AIM Terminal Block.

11. Reconnect the AIM communications cable.