GEMotor Protection System Integrated process, control, and protection for low voltage motors

featured protection for low voltage AC motors

• Advanced automation capabilities providing customized

protection and integrated automation control

• Cost effective solution - Low cost modular design

• Small footprint and compact design - With or without

display, fits into standard MCC buckets

• Preconfigured logic for all standard motor starter types,

EnerVistaTM compatible

• Integrated motor control pushbuttons

• Remote monitoring via serial communications, Modbus RTU

• Easy installation and integration - Panel mount option

• Reduced number of devices - Replaces bi-metal overload

elements, integrates timers, relays, meters, switches,

indicators

• Motor protection and management system for low voltage

AC motors

• Specifically designed for Motor Control Centre applications

• Motor operational parameters and historical data

• Process data

• Phase and ground current, power, energy, voltage

• Status of relay inputs

• Trip record and pre-trip values

• Motor statistical information

Monitoring and Metering

User Interface

Protection and Control

• Motor Thermal Model

• Single phase / Current unbalance

• Contactor failure

• Locked/stalled rotor

• Ground fault

• Undervoltage, Overvoltage

• Overtemperature

• Acceleration Trip

• Thermistor Protection

• Starts per Hour / Time Between Starts

• Undercurrent and underpower

• Configurable motor start controller

• Undervoltage auto restart

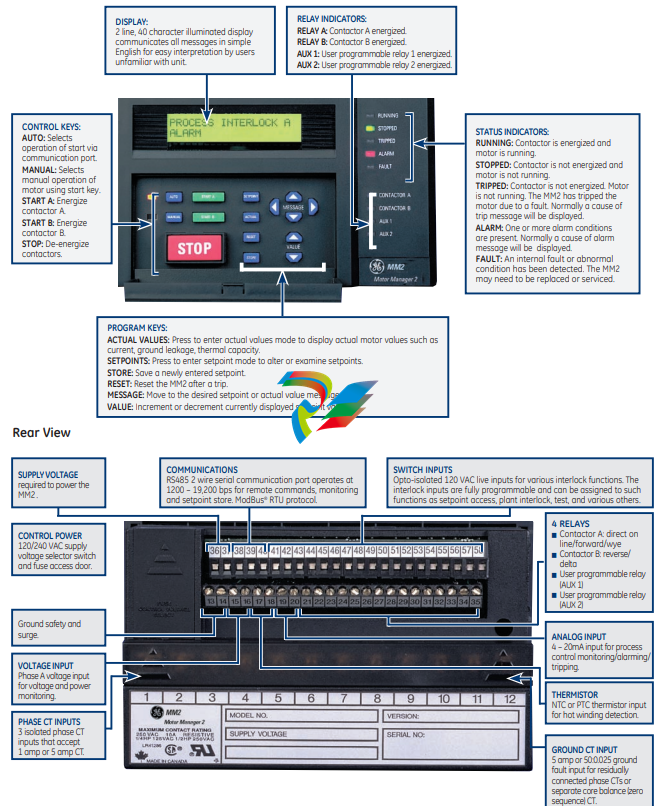

• 40 Character LCD display

• Front Panel control push buttons and programming keypad

• 11 Motor and Relay Status LED’s

• RS485 ModBus™ , 1200 - 19,200 bps

Motor Protection System

Integrated process, control, and

protection for low voltage motors

Features

Applications

K

EnerVistaTM Software

• State of the art software for configuration and

commissioning GE Multilin products

• Document and software archiving toolset to ensure

reference material and device utilities are up-to-date

• EnerVistaTM Integrator providing easy integration of data

in the MM2 into new or existing monitoring and control

systems

Protection and Control

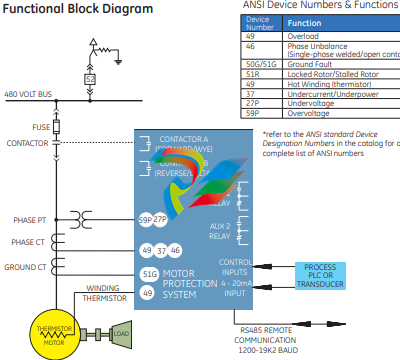

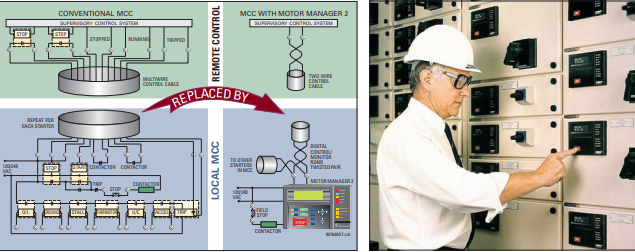

The MM2 is a digital motor protection

system designed to protect and manage

low voltage motors and driven equipment.

It contains a full range of selectively

enabled, self contained protection and

control elements as detailed in the

Functional Block Diagram and Features

table.

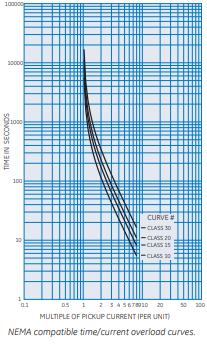

Thermal Overload

An overload trip occurs when the

thermal capacity value equals 100%.

Thermal capacity used is calculated from

accumulated I2t value and chosen

overload curves. True RMS current sensing

ensures correct response to the heating

effect of harmonics. One of 12 different I2t

time overcurrent overload curves may be

selected from eight standard curves and

four NEMA compatible curves.

Phase Unbalance

The MM2 monitors the percentage

unbalance in the motor phase currents. If

a phase current unbalance of greater than

15% exists for more than five seconds an

alarm is generated. If a phase current

unbalance of greater than 30% exists for

more than five seconds a single phase trip

occurs.

Locked/Stalled Rotor

To help prevent damage to mechanical

equipment such as pumps or fans, the

MM2 will trip when the running current

exceeds the stalled rotor trip level after the

programmed time delay. This feature may

be set to ‘OFF’ if desired, and it is disabled

during motor starting.

Ground Fault

The ground fault level is measured as a

percentage of the CT primary. Ground

overcurrent can be detected either from

the residual connection of the phase

CTs or from a zero sequence CT. A delay

time is set to prevent false alarms from

momentary surges. Both a ground fault

alarm and trip are provided. The alarm

can be set below the trip level to provide

an early warning of insulation breakdown.

Overtemperature

An input from motor winding thermistors

is available. The MM2 can accept both

positive temperature coefficient (PTC) and

negative temperature coefficient (NTC)

sensors. A thermistor level can be selected

for both alarm and trip.

Cooling Time

After an overload trip, the thermal

capacity value decreases exponentially

to model the motor cooling characteristic.

An overload trip can be reset when the

thermal capacity value decreases to 15%.

A stopped motor cooling time can be set to

determine how long it takes for a stopped

motor to reach steady state ambient

temperature from its maximum allowable

temperature.

Undercurrent/Underpower

Both undercurrent and underpower alarms

and trips are provided with time delays.

Protection against failed shear pin or loss

of pump flow, which may result in only a

small change in current, is provided by the

underpower alarm.

Undervoltage

For voltage sensitive loads, a drop in

voltage increases the drawn current,

which may cause overheating in the

motor. The undervoltage protection

feature can be used to either cause a trip

or generate an alarm when the voltage

drops below a specified voltage setting for

a programmable time delay.

Overvoltage

An overvoltage on running motor with a

constant load results in decreased current.

However, iron and copper losses increase,

causing an increase in motor temperature.

The current overload relay will not pickup

this condition and provide adequate

protection. The overvoltage element may

be used for protecting the motor in the

event of a sustaine overvoltage condition.

Contactor Failure

The MM2 monitors the contactor while

performing start and stop commands. If

the contactor does not change status an

‘open control circuit’ or ‘welded contactor’

alarm is triggered.

Additional Alarms

The MM2 has programmable alarms to

warn of a number of abnormal conditions.

These include: acceleration time exceeded,

abnormal inverter starter, incomplete start,

motor greasing, contactor inspection,

motor stop time, analog input, and process

interlock switch open.

Starters

MM2 can be programmed to serve as the

following types of motor starters:

• Full Voltage non-reversing,

• Full Voltage reversing,

• Wye/Delta open or close transition

starter,

• Two speed starter,

• Inverter (VSD) starter,

• Slip ring (rotor resistors) and primary

resistance starters,

• Autotransformer open or close

transition starter,

• Duty/Standby starter,

• Soft starter

Undervoltage Auto Restart

The motor can be automatically restarted

after a momentary power loss when this

feature is enabled. When the control

voltage drops below the dropout voltage

the contactors are de-energized. The MM2

can initiate timers to restart selected drives

upon the return of supply voltage. If control

voltage is restored within the programmed

restart time, the motor will be restarted

immediately. If the control voltage takes

longer to be restored, the MM2 can be

programmed to attempt a restart after a

programmed time delay.

Outputs

The MM2 has one or two contactors (A

and B) which are used for motor starting.

There are also two auxiliary programmable

output relays available on the MM2,

which can be assigned to any one of 31

functions.

Switched Inputs

The MM2 has up to six fixed control inputs.

These are used for start A and B, stop, local

isolator, and contactor A and B status. The

MM2 also has up to 10 programmable

switch inputs. Each input can have one

of 33 interlock functions assigned to it. A

function can be assigned to one interlock

input only.

Analog Input

The analog input can be scaled to user

defined values. High and low alarm and trip

setpoints are recorded with time delays.

Monitoring and Metering

The MM2 offers advanced monitoring and

metering which includes:

Metering

The MM2 meters and displays:

• current of each phase

• Ground fault leakage current

• Motor load as a % of full load current

• Thermal capacity used (%)

• % Current unbalance

• Power (kW)

• Energy (kWh)

• Voltage

• Analog input

Trip Record

When the MM2 issues a trip command a

record is generated which includes the

cause and pre-trip actual values.

Statistics and Maintenance

The MM2 records statistical data about

relay and motor operation, allowing the

user to set the interval at which routine

maintenance tasks should be performed.

When the times are exceeded an alarm is

generated. These include:

• Motor greasing interval: number of

hours between bearing lubrication

• Contactor inspection: number of starts

after which the contactor contacts

must be inspected for wear

• Maximum motor stopped time: the

maximum number of hours the motor

can be left shut down

User Interfaces

When ordered with the Panel Mount

option, the MM2 comes equipped with a 40

character display, LED indicators, as well

programming and control push buttons.

Display and Keypad

The MM2 has a keypad and 40 character

display for local control and programming

without a computer. In the event of a

trip, alarm, or start block, the display will

automatically display a clear status

message.

In addition to the programming keys, the

panel mount option also provides 3 control

keys for starting and stopping the motor

locally.

Indicator LEDs

The panel mount MM2 has nine LED’s that

provide the status of the motor and relay

output contacts. Two additional LED’s

indicate whether the relay is in Auto or

Manual control mode.

Communications

The MM2 uses a ModBus® RTU RS485

connection for communication. Up to 32

MM2s can be daisy-chained together on a

single communication channel. The MM2

supports a number of baud rates, ranging

from at 1200 to 19,200 bps. A RS232/485

converter module may be used to connect

a personal computer to the MM2.

Software

The MM2 comes with a Windows®-based

configuration program called MM2PC. It

allows access to all the features of the

MM2 with easy to use, pull-down menus.

Using this program it is possible to:

• Program or modify setpoints

• Load or save setpoints from or to a

disk

• Read actual values from the MM2

• Monitor status

• Read pre-trip data and trip record

• Display dynamic trending of actual values

• Get help on any topic

• Print the instruction manual from disk

Mounting Configurations

The MM2 can be ordered as either a chassis

mount or panel mount relay.

The chassis mount comes with all of the

standard features and may be ordered

with one or both of the option packages.

Setpoints are loaded through the RS485

port using the MM2 PC Setup program.

The panel The MM2 Panel Mount (PD)

option is available when both of the option

packages have been ordered. The panel

mount MM2 is mounted through the front

panel of the MCC, providing complete local

programming and control.

Option Packages

Option package 1 increases the control and

diagnostic features available. It includes:

• Process control and process inputs

• Undervoltage auto restart

• Enhanced diagnostics including alarms,

pre-trip data, and historical statistics

about the use and performance of the

motor and drive

Option package 2 increases the protection

features and input options. It includes:

• Second contactor control, including two

more control inputs

• Single-phase VT input used to calculate

and display the kW and kWh absorbed

by the drive

• Enhanced protection including five

more protection features

• Motor winding thermistor input

EnerVistaTM Software

The EnerVista™ Suite is an industry

leading set of software programs that will

simplify every aspect of using the MM2

relay. Tools to monitor the status of your

motor, maintain your relay, and integrate

information measured by the MM2 into

HMI or SCADA monitoring systems are

available.

EnerVistaTM Launchpad

EnerVista™ Launchpad is a powerful

software package that provides users with

all of the setup and support tools needed

for configuring and maintaining GE Multilin

products. Launchpad allows configuring

devices in real-time by communicating

using serial, Ethernet , or modem

connections, or offline by creating setting

files to be sent to devices at a later time.

Included in Launchpad is a document

archiving and management system

that ensures critical documentation is

up-to-date and available when needed.

Documents made available include:

• Manuals

• Application Notes

• Guideform Specifications

• Brochures

• Wiring Diagrams

• FAQ’s

• Service Bulletins

Viewpoint Monitoring

Viewpoint Monitoring is a powerful yet

simple-to-use monitoring and data

recording package for small systems.

Viewpoint Monitoring provides a

complete HMI package with the following

functionality