Summary of Advant Controller 160

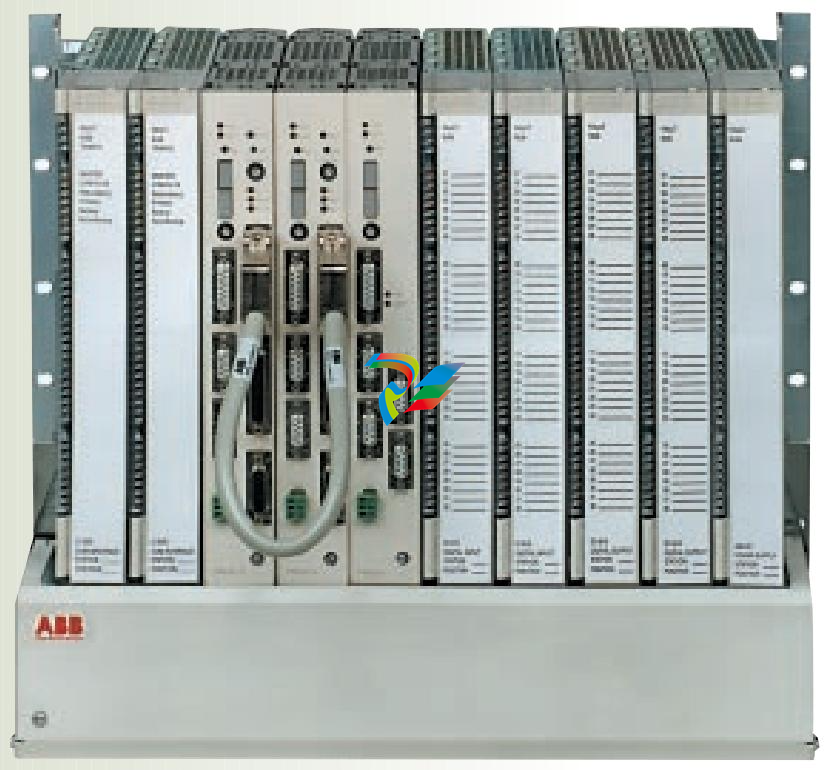

# Advant® OCS Open Control System ## Advant Controller 160 Advant Controller 160, installed with two I/O tiers in one cabinet (I/O connections in the adjacent cabinet). The scalable controller for complex applications The Advant Controller 160 is the most modern in the Advant Controller 100 series. This scalable device, which boasts numerous control and communication functions, was developed for a wide range of industrial applications: for small to medium-sized plants, for logical controls and control loops, as a stand-alone device or integrated into the Advant OCS process control system. The ability to configure all central components redundantly ensures an overall stable system. The scalability with up to 6 controllers per tier is ideal for meeting almost any performance requirement. ## Advant Controller 160: - Masters logical sequence controls as well as control loops, counting and arithmetic functions. It supports real sequential event recording through the time stamping of events received via input modules with a resolution of 1 ms. - Features an RS 232 interface for connection to MODBUS I or for communication with decentralized terminals. - Offers a PROFIBUS-DP interface to support a wide range of applications in manufacturing, process and power plant automation. Manufacturer independence and openness are guaranteed by the PROFIBUS standard EN 50170. - Is designed for both independent and decentralized systems and can be used either as a stand-alone device or in conjunction with other components of the Advant OCS process control system. - With 31 independent tasks whose execution times (minimum 2 ms) can be freely defined by the user, the Advant Controller 160 delivers strong processing performance. - Is a future-proof device as it can be expanded in various ways and programmed online. - Is programmed in AMPL via the Advant Station 100 Engineering Station. - Stores application programs in a non-volatile memory without battery buffering. The program memory can be electrically erased and thus is immediately reprogrammable. - Provides password protection against unauthorized access. ## ABB Advant Controller 160 – when availability matters Advant Controller 160 with redundant central units and a central unit for the MVI interface ## Expandable for all plants The Advant Controller 160 can be expanded and modified in various ways, making it particularly well-suited to adapt to changing plant conditions. The simplest solution in this context is the addition of I/O modules; this process can be carried out online, i.e., without switching off the controller. The Advant Controller 160 can also be expanded by adding additional I/O tiers. A third option is to connect multiple Advant Controller 160 stations to a decentralized system via the high-performance Advant Fieldbus 100; in this way, up to 80 stations can be interconnected. To meet even the most demanding reliability criteria, the Advant Fieldbus 100 can be fully redundantly wired and equipped with redundant interfaces. Both coaxial and twisted-pair bus cables are available for selection to achieve different bus lengths. Fiber-optic cables and modems provide protection against electromagnetic interference. ## Open communication It is now easier than ever to combine Advant control systems with OPC-compatible software of your choice. Available visualization systems from ABB include, for example, AdvaSoft for Windows or SattGraph 5000. The Advant OPC Server, which is based on Windows NT, provides powerful, easy-to-use services for reading, writing and subscribing to data. Thus, it is simple to implement a wide variety of applications for the control and monitoring of production processes. The Advant OPC Server software gives applications that support the OPC standard access to real-time process and production data in ABB Advant control systems. The Advant OPC Server for Advant Fieldbus 100 can coexist with other Windows NT-based configuration tools, such as AMPL Control Configuration. This combination offers, among other things, the possibility of configuration via networks and troubleshooting for nodes on the Advant Fieldbus 100. This means you can configure, commission and maintain all your stations in the control system from a central point – with a minimum of effort. ## Everything is correct, including the system connections ... As part of the Advant OCS automation system, the Advant Controller 160 communicates with the system via the Advant Fieldbus 100. Since it can be networked with third-party systems via serial interfaces, the controller is the ideal medium for integrating PLC components into process and plant control systems. ## System configuration shows various communication possibilities of the Advant Controller 160 ## ... and the reliability of the system For use in complex control engineering applications, all essential functions of the station can be configured redundantly, including data processing, power supply, interfaces to the Advant Fieldbus 100 and I/O bus extensions. Switching to other devices, even to other central units, is completely seamless and transparent. ## Graphical application development The Advant Controller 160 is configured with the Function Chart Builder function plan editor in AMPL. AMPL is the uniform configuration and programming language for graphic applications used throughout the Advant OCS process control system in conjunction with the master software, and handles logical links, arithmetic functions and continuous control tasks equally well. Application programs are developed graphically page by page by selecting the appropriate function blocks and connecting them internally and to the process. Application programs look the same on paper as they do on the screen, which can be particularly advantageous for troubleshooting: the printout provides an overview, and the screen delivers the details. In addition, signal values can be updated during operation and configured signals can be traced back to their source. ## Optimal process connections To establish digital and analog inputs and outputs, various I/O modules of the S600 series can be connected to the Advant Controller 160. The I/O area is designed for both alternating current and direct current and is equally suitable for inexpensive modules with high signal density as well as for high-performance modules with kV isolation. Also available is an intelligent pulse counter module for precise length measurement and positioning, which can process pulse frequencies of up to 100 kHz. In addition, a speed input module with integrated shutdown logic, which is used to control turbines and other rotating machines, can be connected to the system. All S600 I/O modules are enclosed in a sheet metal housing (protection class IP20) to provide protection against electromagnetic interference in the tier and against mechanical damage from the outside. Field cables are connected via terminals to a plug contact strip that is plugged onto the front of the module – a space-saving and clean solution. Distributed input/output devices of the S800 I/O series can be coupled to the Advant Fieldbus 100. You can install up to 32 such input/output devices. ## Technical Information ### Alternative power supply Digital inputs 24 V DC - 32 channels, non-isolated (DI610) - 32 channels, isolated in four groups (DI620) - 32 channels, isolated in four groups (DI650) 48 V DC Direct (input non-isolated) 19.2-30 V DC 33 MHz 3.0 MB 33 MHz 3.5 MB max. 125 Slaves max. 12 MBit/sec. DC (input isolated) 110-125/220-250 V DC AC (input isolated) 110/120/220/240 V, 47-450 Hz ### Basic performance features Central unit PM 640 and PM 644: (Supports SC 610) - 32 channels, isolated in four groups (DI621) - 32 channels, isolated in four groups (DI651) 60 V DC - 32 channels, isolated in four groups (DI622) - 32 channels, isolated in four groups (DI652) 120 V AC Clock frequency: Program memory, Flash-PROM Central unit PM 645A: (redundant processing) Clock frequency: Program memory, Flash-PROM PROFIBUS-DP Interface (PM644) Bit rate - 16 channels, isolated in four groups (DI635) 230 V AC ### Basic communication connections - 16 channels, isolated in four groups (DI636) Digital outputs 24 V DC PM 640: RS 232C for Advant Engineering Station 100 RS 232C interface for MODBUS I PM 645A: - 32 channels, max 200 mA, short-circuit proof, non-isolated (DO610) RS 232C for Advant Engineering Station 100 RS 232C interface for MODBUS I - 16 channels, max 2.4 A, short-circuit proof, isolated in 8 groups (DO625) < 60 V DC RS-422 (fast serial connections) - 32 channels, max 0.5 A, short-circuit proof, isolated in four groups (DO620) 24...250 V AC/DC Integrated majority voting (redundancy management) Total I/O performance max. 1,500 max. 75 max. 7 max. 2 max. 10 - 16 channels (relay). Load current: max. 2 A, min. 20 mA. Switching capacity: AC: 500 VA, DC: 40 W (DO630) Pulse counting <100 kHz, 5 or 24 V or ±13 mA DC - 5 counters, each with 2 inputs, 1 strobe and 1 set (24 V only) inputs, each input individually optically isolated. Counting modes: up, down, frequency, differential, position, speed measurement ### Hardware options Advant Fieldbus 100 redundant, coaxial cable, two CI630 Advant Fieldbus 100 (AF 100) redundant, coaxial cable, one CI630 CI631 for subordinate, redundant AF 100 and S800 I/O connection max. 1 redundant pair Interface module carrier SC610 Supports communication protocols RCOM/RCOM+ and - RCOM/RCOM+ interface, CI532V01, 2 channels - MODBUS I interface, CI532V02, 2 channels - Siemens 3964R, CI532V03, 2 channels Event handling on digital input modules DI650/DI651/DI652, Advant Fieldbus 100, and/or RCOM/RCOM+. ### Analog inputs 0...20mA - 32 channels, unipolar, 12-bit resolution (AI610) - 16 channels, isolated as a group, 12-bit resolution, CMR=50V, (CMRR >100 dB) (AI625) ±10V/ ±20 mA - 16 channels, differential, 12-bit resolution, CMV=100V, CMRR >80 dB (at 16, 33, 50 or 60 Hz) (AI620) Pt100 or resistance - 12 channels, -200...600°C or 0...500Ω, 0.5 V, 3- or 4-wire, isolated as a group, 13-bit resolution, CMRR>100dB (AI630) ### Thermocouples - 14 measuring + 2 reference channels, measuring range C and J, isolated as a group, 12-bit resolution, CMRR >120 dB (AI635) ### Analog outputs 0…20mA - 16 channels, isolated as a group, 12-bit resolution (AO610) ±10V/ ±20 mA, 4-20 mA, 0-5V, 0-10V, 1-5 V - 8 channels, individually isolated, 12-bit resolution (AO650) ### Notes 1 For details on the Advant Controller 160, see the manual on Advant OCS. 2 The CI532Vxx module is plugged into an SC610 module. Central unit PM640 required. 3 A practical (i.e., not an ultimate theoretical) limit. 4 With event detection (time stamping) or pulse acquisition functionalities. 5 Can be installed in the enclosures of various cabinets. 6 Corresponds to NEMA protection classes 1, 2 and 5. 7 Specific specifications for slot allocation. 8 Termination of unused monitored analog input required. 9 Standard version. 10 Extended version, with second AF 100.