parkerFunctional Safety Manual VM600 Machinery Protection Safety Integrated System

PREFACE

About This Manual

This manual provides reference information on using Vibro-Meter’s VM600 Series systems in functional

safety contexts. It is applicable to the following VM600 systems:

• Machinery Protection System (MPS).

Who Should Use This Manual?

The manual is written for the designers and operators of process monitoring and process control systems

using Vibro-Meter’s VM600 Series systems.

The system designers and operators are assumed to have the necessary technical training in safety

engineering, electronics and mechanical engineering (professional certificate/diploma or equivalent) to

enable them to install, program and use the system(s).

Structure of the Manual

This section gives an overview of the structure of the document and the information contained within it.

Some information has been deliberately repeated in different sections of the document to minimize

cross-referencing and to facilitate understanding through reiteration.

The chapters are presented in a logical order. You should read those that are most relevant to you and

then keep the document at hand for future reference.

The structure of the document is as follows:

Chapter 1 Introduction

Explains the purpose and scope of this document.

Chapter 2 Certification

Highlights the VM600 system certification achieved.

Chapter 3 Safety Issues

Provides information on the safety issues related to the use of a VM600

system in a functional safety context.

Chapter 4 Disposal

Provides advice on how to dispose of your electrical and electronic

equipment at the end of its life.

Chapter 5 Customer Support

Provides contact details for technical queries and for getting equipment

repaired. Includes a customer feedback form allowing the user to provide us

with valuable feedback on our documentation.

Symbols and Styles Used in This Manual

The following symbols are used in this manual where appropriate:

NOTE : This is an example of the NOTE paragraph style. This draws the operator’s

attention to additional information or advice relating to the subject.

Important Remarks on Safety

Additional Remarks

Every effort has been made to include specific safety-related procedures in this manual using

the symbols described above. However, operating personnel are expected to follow all

generally accepted safety procedures.

Safety procedures should be communicated to all personnel who are liable to operate the

equipment described in this manual.

Vibro-Meter does not accept any liability for injury or material damage caused by failure to

obey any safety-related instructions or due to any modification, transformation or repair

carried out on the equipment without written permission from Vibro-Meter. Any modification,

transformation or repair carried out on the equipment without written permission from

Vibro-Meter will invalidate any warranty.

The WARNING safety symbol

THIS INTRODUCES DIRECTIVES, PROCEDURES OR PRECAUTIONARY MEASURES WHICH

MUST BE EXECUTED OR FOLLOWED. FAILURE TO OBEY A WARNING CAN RESULT IN

INJURY TO THE OPERATOR OR THIRD PARTIES.

The CAUTION safety symbol

This draws the operator's attention to information, directives or procedures

which must be executed or followed. Failure to obey a caution can result in

damage to equipment.

INTRODUCTION

1.1 Purpose

The purpose of this document is to describe the use of a VM600 machinery protection system

(MPS) in a functional safety context as defined by IEC 61508 and ISO 13849-1.

1.2 Scope

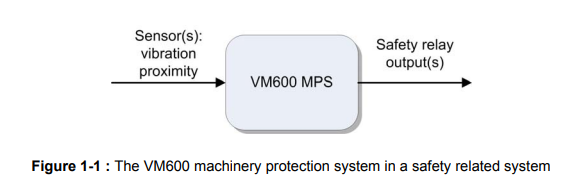

The document applies to VM600 series machinery protection systems as outlined below in

Figure 1-1 and Table 1-1

Part Description Mandatory Comment

ABE04x Rack Yes 19” rack

RPS6U Power supply Yes Two PSUs should be used.

The PSUs can be AC or DC.

MPC4 Machinery protection

card (4+2 channels) Yes 1 to n cards

IOC4T Input/output card Yes 1 per MPC4 card

RLC16 Relay expansion card No

MPS1 Software Yes

Warning

The following symbol introduces directives, procedures or precautionary measures which

must be executed or followed.

FAILURE TO OBEY A WARNING MIGHT RESULT IN INJURY TO THE OPERATOR OR THIRD PARTIES AND

DAMAGE TO EQUIPMENT.

1.4 Reference Part Numbers

Part Number Card / Product Name

204-040-100-012 Standard 19” rack

204-040-100-112 Standard 19” rack insulated version

204-040-100-211 Standard 19” rack CSA standard

204-042-100-012 Standard 19” rack Siemens standard

204-042-100-211 Standard 19” rack Siemens CSA standard

200-510-071-113 MPC4

200-560-000-113 IOC4T

200-570-000-111 RLC16

200-582-200-013 RPS6U 24VDC

200-582-300-013 RPS6U 48VDC

200-582-400-011 RPS6U 72VDC

200-582-600-013 RPS6U 110VDC

200-582-500-013 RPS6U 110/230 VAC

209-500-100-022 MPS1 software (used to configure cards)

CERTIFICATION

The VM600 system as described in this document is certified by TÜV® NORD to the following

levels:

• IEC 61508 Safety Integrated Level 1

• ISO 13849-1 performance level C.

A scanned copy of the safety certificate issued by TÜV® NORD is shown on the following

page (see Figure 2-1)

SAFETY ISSUES

3.1 VM600 in a Safety Related System

When a VM600 is part of a safety related system (SRS), certain configuration restrictions

must be applied. In particular:

• The output relays must be configured as de-energized to trip. Specifically:

• the relay is energized when the monitored levels are within their specified tolerances

• the relay is de-energized to indicate an alarm.

• The use of the VM function danger bypass is not allowed.

• The use of the VM function trip multiply is not allowed.

• The alarm must be defined as ‘latching’.

3.2 Valid Safety Configurations

The VM600 machinery protection system (MPS) can be configured in many different

arrangements. These configurations are described in more detail in the hardware manual

(see 1.5 - Applicable Documents). For example, the VM600 can be used to protect rotating

machines in a safety related system.

Monitored Signal Valid for SRS Reference in HW

Manual

Broad-Band Absolute Bearing Vibration Yes Section 7.1

Tracking No Section 7.2

Relative Shaft Vibration with Gap Monitoring Yes Section 7.3

Absolute Shaft Vibration Yes Section 7.4

Shaft Position Yes Section 7.5

Safety Inputs and Outputs

Monitored Signal Valid for SRS Reference in HW

Manual

Broad-Band Absolute Bearing Vibration Yes Section 7.1

Tracking No Section 7.2

Relative Shaft Vibration with Gap Monitoring Yes Section 7.3

Absolute Shaft Vibration Yes Section 7.4

Shaft Position Yes Section 7.5

Table 3-1 : Overview of valid safety configurations

Signal Comments Reference in HW

Manual

MPC4 CH1-CH4 (inputs) Ensure cabling follows the

guidelines Table 9-1 part 1

MPC4 relay contacts (outputs) Table 9-1 part 2

Safety Function

With reference to IEC 61508 the safety function for the system is defined below.

For the required safety function SF1, the following safety parameters (SP) are required in

accordance with IEC 61508.

SF

Number Description Safe State

Required

Safety

Parameters

SF1

If an input value (or values)

exceed(s) a predefined limit,

then a trip activation signal is

made.

De-energize to trip (open relay

contact).

That is, the EUC and the

VM600 interpret a

de-energized state as a safe

state.

See table

below

SP

Number Safety Parameter Requirement Comment

SP1 Safety integrity level SIL 1

SP2 Operational mode Low demand mode

SP3a Component type sensor Type B

Component type logic

(measuring logic) Type B

Component type

actuator (relay) Type A

SP4 Hardware fault tolerance

(HFT) 0

Single channel architecture

of an already existing

proven-in-use system

should be used for SIL 1

application without any

changes

SP5 Probability of failure on

demand (PFD) ≥ 10-2 to 10-1

PFD by proof test years

FMEDA

0.5 1.0 2.0 5.0

5.5e-3 1.1e-3 2.2e-2 5.0e-2

SP6

Safe failure fraction

(SFF) for Type A

subsystem

< 60% for SIL 1 and

HFT 0

Safe failure fraction

(SFF) for Type B

subsystem

60% to < 90% for SIL 1

and HFT 0

In practice, the output relay or relays are normally the ‘input’ to a safety related PLC that takes

this input together with other safety related signals.

3.5 ISO 13849-1 Performance Level

The table below shows the breakdown of performance level (PL) by diagnostic coverage and

mean time to dangerous failure (MTTFd).

Safety Time

After the defined safety level threshold has been exceeded, the VM600 system will open the

associated safety relay within 100 ms.

3.7 Protection of Relay Contacts

In a safety system it is important to protect against a relay contact becoming welded due to

excessive current being inadvertently passed. Therefore, the outputs must be protected by a

5A(T) fuse

nstallation

The system shall be installed following the procedures described in the MPS Hardware

Manual (Standard Version) MAMPS-HW/E (see 1.5 - Applicable Documents). Environmental

restrictions are described in Appendix A of the manual.

3.9 Configuring the System

It is important that the levels (vibration and so on) are adjusted to suit the system under

protection and that a manual verification is made of the parameters that are uploaded to the

system (MPC4 card).

Note that the procedures described should only be performed by competent and authorized

personnel following the plant specific guidelines in force at the installation site.

3.9.1 Define the levels

The choice of alarm levels must be made in consultation with the site manager. It is the end

user’s responsibility to ensure that the alarm levels are appropriate for the particular system

being protected.

The levels are defined using the MPS1 software (supplied) or the MPS2 software (optional).

Please refer to the appropriate documentation for complete information.

3.9.2 Define the alarm outputs

Any relay on the MPC4 or RLC16 cards can be configured to provide the safety function. As

previously noted, the alarms must be:

• configured as ‘latching’

• de-energized to ‘trip’.

3.9.3 Upload the levels and configuration

Once the system parameters have been correctly defined using the MPS software, the

configuration for each MPC4 card must be uploaded to the card. This procedure is described

in the MPS1 Software Manual MAMPS1-SW/E (see 1.5 - Applicable Documents).

3.9.4 Configuration verification

Whilst the actual upload of data is controlled by CRC verification and other techniques, in

order to fulfil the IEC 61508 requirements a manual verification of this upload is required. The

verification is made by downloading the configuration from the MPC4 card to the computer

and comparing the data received with the original data uploaded to the card.

This procedure is described below.

• Select the appropriate MPC4 card on the MPS software (as used in 3.9.3 - Upload the

levels and configuration).

Use the Dump to File option to save the configuration as pc_card_1.csv.

• Define a dummy rack using a Tag name from_sys_1.

• Select this rack, connect to the MPC4 card concerned and read its configuration back to

the computer.

• Dump this file as sys_card_1.csv.

• Using the MS-DOS fc (file compare) command, compare the two files. The only

difference should be the download time as shown in Figure 3-1.

3.10 Commissioning

The system should be commissioned as an integral part of the overall SIS commissioning.

INSTALLATION AND COMMISSIONING SHOULD ONLY BE PERFORMED BY COMPETENT AND

AUTHORIZED PERSONNEL FOLLOWING THE PLANT SPECIFIC GUIDELINES IN FORCE AT THE

INSTALLATION.

3.10.1 Guidelines for commissioning

Installing a VM 600 system is fully described in section 8 of the MPS Hardware Manual

(Standard Version) MAMPS-HW/E.

Offline Proof Test

When the VM600 is taken offline, the attached system and equipment are no longer

protected. Therefore, this procedure should only be undertaken by authorized personnel

respecting the overall plant operations procedures. There should be no need to remove the

equipment from site to perform these tests unless it is considered more convenient.

The offline proof test reveals any dangerous faults that might not be detected in normal

operation.

For a VM600 system the proof test must be performed every 5 years or less.

3.12 Repair and Maintenance

If the VM600 system is under maintenance or repair, then the attached system and

equipment may no longer be protected. Therefore, this procedure should only be undertaken

by authorized personnel respecting the overall plant operations procedures.

3.12.1 Guidelines for the proof test

3.12.1.1 Reset

1- Reset the system by performing a cold start. That is, turn off and then turn on the rack.

2- Verify the safety relay status by performing a continuity test.

3- Observe the diagnostic LEDs and note any abnormalities. Refer to the MPS hardware

manual for further information.

3.12.1.2 Threshold tests

These tests are essentially a sub-set of the site commissioning plan. As such, they will vary

widely depending on the number of channels configured, the sensor type, and so on.

The levels used have to be determined for each particular installation. An example for one

channel of a vibration alarm is given below.

1- Disconnect the IOC4T from the sensor cables.

2- Simulate an N1 vibration signal at a site specific frequency for 100% RPM.

3- Inject a signal at (0.8 x alarm level) and verify that the system does not trip.

4- Inject a signal at (1.2 x alarm level) and verify that the system does trip.

3.12.1.3 Maintenance

System maintenance should be performed following the guidelines in the MPS Hardware

Manual (Standard Version) MAMPS-HW/E (see 1.5 - Applicable Documents). When the

VM600 is taken offline, the attached system and equipment are no longer protected.

Therefore, maintenance should only be undertaken by authorized personnel respecting the

overall plant operations procedures.

DISPOSAL

If it is decided to scrap a VM600 system, then it must be disposed of in an environmentally

friendly manner. In European Community countries, the Waste Electrical and Electronic

Equipment (WEEE) directive is applicable.

• According to the WEEE Directive 2002/96/EC, all waste electrical and electronic

equipment should be collected separately and then treated and disposed of in

accordance with the best available and environmentally friendly techniques. Waste

electrical and electronic equipment may contain substances hazardous to the

environment (and to humans) but it is also a valuable resource of new raw materials.

Therefore, it is important to collect electrical and electronic waste separately from other

waste.

CUSTOMER SUPPORT

5.1 Contacting Us

Vibro-Meter’s worldwide customer support network offers a range of support including 5.2 -

Technical Support and 5.3 - Sales and Repairs Support. For customer support, please

contact your local Vibro-Meter representative. Alternatively, contact our main office:

Customer support

Vibro-Meter SA

Route de Moncor 4

PO Box 1616

CH-1701 Fribourg

Switzerland

Telephone: +41 (0)26 407 11 11

E-mail: energysupport@ch.meggitt.com

Web: www.vibro-meter.com

Vibro-Meter SA is an operating company of Meggitt PLC.

5.2 Technical Support

Vibro-Meter’s technical support team provide both pre-sales and post-sales technical

support, including:

1- General advice

2- Technical advice

3- Troubleshooting

4- Site visits.

NOTE : For further information, please contact Vibro-Meter (see 5.1 - Contacting Us).

5.3 Sales and Repairs Support

Vibro-Meter’s sales team provide both pre-sales and post-sales support, including advice on:

1- New products

2- Spare parts

3- Repairs.

Customer Feedback

As part of our continuing commitment to improving customer service, we warmly welcome

your opinions. To provide feedback, please complete the Customer Feedback Form on page

5-5 and return it Vibro-Meter’s main office (see 5.1 - Contacting Us).

.png)

.png)

.png)