METSOmaxPAC Hardware Reference Guide

maxPAC

Input/Output Subsystem

Overview

The maxPAC Input/Output System links the maxDNA Distributed Control

System to real world process control inputs and outputs. The Input/Output

system uses a compact design to provide the system with greatly enhanced

I/O capacity in relatively little space. A close relationship exists, in turn,

between this I/O system and the maxDNA Distributed Processing Unit

(DPU) which it serves.

The DPU and the I/O modules mount in an I/O chassis assembly. The

backplane in the chassis assembly provides the I/O bus connection between

the DPU and the I/O modules. It also provides the system power and field

power connections to the modules. Multiple I/O chassis that share the I/O bus

can be installed in a cabinet.

Model IOP I/O Subsystem

Cabinet

Two standard cabinet types are available for the mounting of I/O system

hardware. The cabinet is available as either a NEMA (National Electrical

Manufacturers Association) type 1 or 12 and consists of the following:

Welded steel construction

Front and Rear access

I/O mounted in front and rear of cabinet (standard)

I/O mounted in front and terminations in rear of cabinet (option)

Other mounting arrangement options are also available

Removable doors

19” rack mount rails with standard E.I.A. hole spacing

Top or bottom Cable access

Size 85 7/8” h x 24 ¾”w x 38 7/8”d

Optional Cabinet styles and sizes are also available.

The following figure shows a typical cabinet arrangement with I/O in both

the front and rear of the cabinet.

Figure 1-1. Typical Cabinet Arrangement, Front and Rear Views

Chassis Assembly

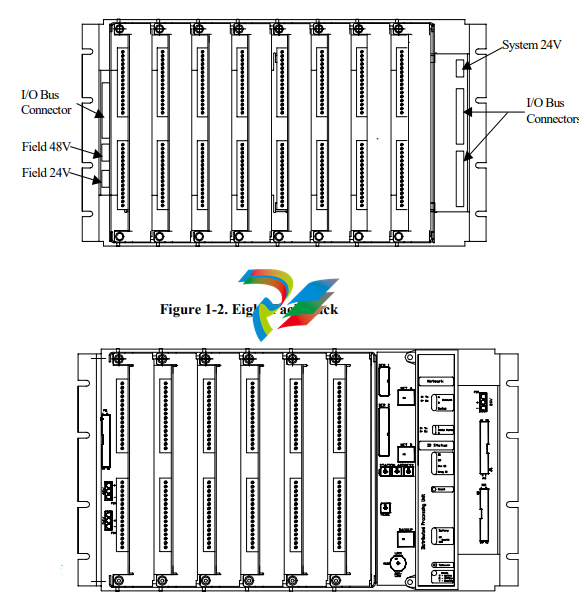

Three chassis assembly types are available for the installation of the I/O

module as follows:

IOP382 Eight-pack assembly to accommodate up to eight maxPAC I/O

modules. The DPU4F can also reside in this chassis.

IOP383 Six-pack assembly to accommodate a DPU4E or a Model 564 I/O

module in the right most position along with six maxPAC I/O modules; the

DPU4E takes up the equivalent of two maxPAC I/O module positions.

IOP381 Four-pack assembly to accommodate four maxPAC or Model 564

I/O modules.

The rack assemblies contain an I/O backplane featuring edge connectors for

I/O modules and connectors for 24V system supply and 24V and 48V loop

power supplies. Input/Output modules connect to the I/O bus through four to

eight connectors on the backplane, depending on chassis style.

The backplane also contains ribbon cable connectors to interconnect chassis

assemblies and extend the I/O bus to the maximum number of modules

supported by the DPU.

DPU Mounting

DPU4E mounts in the right most position of the six-pack chassis assembly. It

occupies the equivalent of two I/O modules. Refer to Publication 278590 for

DPU4E information. DPU4F mounts in the left most position of the eightpack chassis assembly. It occupies the equivalent of one I/O module. Refer to

Publication 278705 for DPU4F information.

I/O Modules

The I/O modules are rugged enclosed printed circuit board assemblies. The

edge connection at the rear of each module provides the interface to the

backplane and the I/O bus. System power and field power, when applicable, is

also available through this connection.

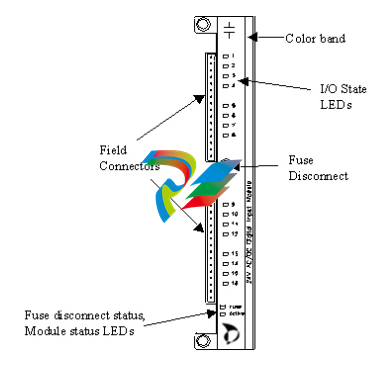

While I/O modules vary by type, they may include one or more of the

following:

A color bar on the module faceplate identifies the module type. Each

module type has a unique color.

Euro-style terminal connector blocks for field wiring; each block contains

16 connectors;

Rotary address switch;

Light Emitting Diodes (LED) for module status indication;

All the modules that require field power include a front mounted fuse

disconnect and a LED fuse status indication;

All discrete modules include front mounted LEDs for input/output logic

state;

The TC module includes front-end connectors with thermistors to measure

the junction temperature for cold junction compensation.

The I/O modules may be inserted and withdrawn safely with 24 Vdc and field

power applied.

I/O Module Types

Because of the variety of input and output ranges needed in distributed control

applications, the Model IOP I/O offers many types of easily configurable

discrete and analog I/O modules. For a list of modules, along with their

ranges and number of points per module, refer to the following tables.

Digital Input (AC/DC)*

Part Number Description

IOP330 24 Vdc common input; 16 channels

IOP334 24 Vdc isolated input; 16 channels

IOP331 48 Vdc common input; 16 channels

IOP332 120 Vac/dc isolated input; 16 channels

IOP333 240 Vac/Vdc isolated input; 16 channels

IOP350 Form C relay; 10 channels

IOP351 Form A/B relay; 16 channels

IOP335 Pulse I/O , 8 channels

*ac Voltages/currents are RMS

The maxDNA Input/Output System uses the Model APS Power Supply

Assembly, which provides 24V dc power for Distributed Processing Units

and I/O. This Power Supply Assembly consists of a 19-inch rack mount or

flush mount chassis accommodating up to six independent 10 amp power

supply modules. Metso Automation typically installs the power supply

modules in an N + 1 redundancy configuration. Because each module is

individually isolated, the chassis can be split to provide both system power

and loop power.

Power supply features consists of the following:

Redundant AC power inputs

250 Watt power supply modules

Hot replaceable

Current Sharing

Power factor correction

Front panel indicators on each module

AC input

Output voltage status

Output current level

External status signals

Field Termination Options

A maxPAC system uses three field cable termination approaches:

Local Terminations Field cables terminate directly on the I/O

module.

Remote Terminations Field cables terminate on terminal blocks

remotely to the I/O module with an

interconnecting cable back to the I/O module.

Termination Assemblies The QuadPAT, Turbine Valve and Overspeed

modules require a DIN rail mounted termination

assembly. Field cables terminate on this

assembly with an interconnecting cable back to

the I/O module.

Local Terminations (standard)

Each I/O module is supplied with two 16 point, “Euro-Style” screw clamp

plugs that mate to the Printed Circuit Board Header on the module. Field

cables would be routed directly to these Euro-Style plugs, which can accept

up to a #12awg conductor.

Remote Terminations (option)

Many remote field cable termination options are possible. Listed below are a

few examples:

I/O in front of cabinet, terminations in the rear of cabinet.

Termination cabinet mounted adjacent to I/O cabinet.

Termination cabinet located remotely from I/O cabinet.

The types of terminal blocks installed in the termination facility are too

numerous to list; typically these terminations are DIN rail style. The cabling

back to the I/O module is typically made using two multi-conductor cables,

one to each of the Euro-Style plugs supplied with the individual I/O module.

Termination Assemblies

Part Number Description

IOP337 QuadPAT Termination Assembly

IOP342 Turbine Valve Termination Assembly

IOP346 Turbine Overspeed

CTO301 QuadPAT Module to Termination Assembly Cable

CTO302 Turbine Valve Module to Termination Assembly Cable

CTO303 Turbine Overspeed Module to Termination Assembly

Cable

Installing Model IOP I/O Equipment

This section covers the physical mounting and installation of the Model IOP

I/O equipment. See "Module Mounting Considerations," before mounting

any equipment.

The following tools and hardware are required:

Screwdriver

Hex Key Wrench, Metso Part No. 064598

Mounting Screws, Metso Part No. 030162 (8 per unit supplied)

Nut Retainers, Metso Part No. 003530 (8 per unit supplied)

Crimp Tool for field connectors, Weidmuller Part No. 906480

Crimp Contact Removal Tool, Weidmuller Part No. 906481

Before mounting any hardware, see "Cabling, Power, and Ground Wiring."

Sequence of Mounting Operations

Mounting the parts of the Model IOP I/O in proper order can save time and

duplication of effort.

Follow this sequence as closely as possible for best results:

1. Refer to field wiring instructions that can influence mounting locations

for chassis assemblies and chassis assembly/module replacement.

2. Mount the chassis assemblies; see "Mounting I/O Chassis Assemblies."

3. Perform all steps as outlined in "Cabling, Power, and Ground Wiring."

5. Complete field wiring.

6. Refer to "Module Addressing" for switch settings and jumper selections.

7. Install I/O modules.

If your field wiring enters through the bottom of the cabinet, mount the

Model IOP I/O units from top to bottom. This will make wiring of future

units easier, since you will not have to pull wires from the bottom of the

cabinet past existing Model IOP I/O units. This same reasoning applies to

field wiring entering the top of the cabinet. Here you mount the Model IOP

units from bottom to top.

Mounting I/O Chassis Assemblies

The Model IOP I/O chassis assembly attaches to the rear mounting rails in

standard 19-inch maxDNA I/O cabinets. Three chassis styles are available.

See “Chassis Assembly.” Up to seven chassis assemblies may be installed in

a standard cabinets.

Usually, the Model IOP I/O units are supplied already mounted in cabinets,

but if you are mounting them yourself, follow this procedure.

Note: before you mount an I/O chassis, it should contain the I/O backplane.

To attach the chassis assembly:

1. At the desired chassis assembly mounting location in the cabinet, place

eight 10-32 nut retainers (Metso Part No. 003530) in the rear mounting

rail holes that correspond to the eight screw slots on the Model IOP

chassis assembly.

2. The holes in the maxDNA cabinet rear mounting rails are arranged in a

repeating pattern of two holes close together separated by a single hole.

To make sure all chassis assembly mounting screw cutouts line up to

corresponding mounting rail holes, you must align the top mounting

screw cutouts (left and right) of the chassis assembly with the top holes

(left and right) of two hole pair.

3. Position the chassis assembly (two ribbon connectors to the right) so that

the screw slots align with the nut retainers. Insert eight 10-32 mounting

screws (Metso Part No. 030162) and tighten securely.

Cabling, power wiring, and chassis assembly to cabinet frame grounding

should be completed before mounting the I/O modules. See next section.

Cabling, Power, and Ground Wiring

This section describes power wiring, Model IOP I/O connection, and

connection to other Model IOP I/O units. The connections covered in this

section should be done after the chassis assemblies are in place and before

the I/O modules are mounted. Some cabling can be done when the I/O

modules are mounted, but the job is easier when they are removed. (See also

Interconnecting I/O Racks).

Cables used in the maxDNA Distributed Control Systems are labeled at both

ends with the device and connector number. Interconnecting ribbon cables

are designed for specific orientation, however, the connectors still prohibit

wrong electrical connection.

Refer to Publication 278561, System Power and Grounding, for a discussion

of cabinet grounding.

Supplying 24V Power to the I/O Modules

The I/O system requires a 24 Vdc ±4.0 Vdc power supply. Normally, this is a

maxDNA power supply mounted in the cabinet holding the DPU; to ensure

reliability, Metso Automation recommends using a maxDNA power supply

exclusively. If another 24 Vdc power supply is used, it must meet the same

specification requirements as the maxDNA supply. All modules are

individually fused. The CMOS technology in the Model IOP I/O design

results in low module power consumption.

Whether the power source is the standard maxDNA supply or another

supply, the +24 Volts connector plugs into the 24V connector on the right

side of the I/O backplane.

Caution: The +24 Vdc power supply used to power any maxDNA hardware

should never be used for external relay contact wetting or to power any other

field equipment. Use a separate supply for contact wetting to provide noise

and interference protection for the maxDNA hardware.

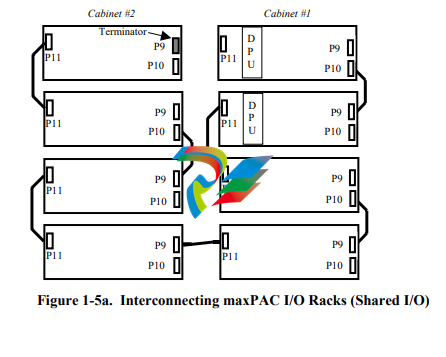

Interconnecting I/O Racks

Use a ribbon cable to interconnect, in a daisy chain manner, two or more

adjacent I/O chassis assemblies in the same maxDNA I/O cabinet group. The

cables should be installed in a manner that minimizes the total I/O bus length.

This is done by utilizing the I/O bus connectors on both ends of the racks so

that the bus “flows through” the racks.

For example, consider the two-cabinet system shown in Figure 1-5a. A

maxDPU4F pair is installed in the leftmost slots of the top two racks in

cabinet 1. The bus begins at the DPU and flows through the rack to the

connectors on the right side of the rack (P9 & P10). A ribbon cable connects

the right side of rack 1 to the right side of rack 2. The bus flows through

rack 2 to connector P11. Another ribbon cable connects the left side of rack

2 to the left side of rack 3. The bus flows through rack 3 to connectors P9

and P10. This same pattern is repeated until the last rack has been reached.

Notice that the bottom rack of cabinet #1 is connected to the bottom rack of

cabinet #2 by a cable that runs from P11 to P9. This is because that results in

a shorter cable length than it would be had it run from P11 to P11. It is also a

much shorter cable length than if it had been run from the bottom of cabinet

1 to the top rack in cabinet 2.

To reiterate, when cabling the I/O racks together, the goal is to keep the I/O

bus length as short as possible. Connecting the cables on alternate sides of

the racks so that the I/O bus “flows through” from one rack to the next does

this.

Note that the ribbon cable connectors are keyed. The color stripe on the

ribbon cable should match pin 1 on the backpanel connector. Connector pin

1 is indicated by a white triangle symbol on the backpanel adjacent to the

connector.

A bus terminator (CPO402) must be installed at the end of the I/O bus

farthest from the DPU. The bus terminator is a small PC card assembly that

is designed to plug in to the I/O bus connector. When installing a terminator,

be sure to match its pin 1 indication to the pin 1 indication on the backpanel.

In Figure 1-5a, the terminator is shown inserted into connector P9 of the top

rack in cabinet 2. That is the point on the bus that is farthest from the DPU.

If you add I/O racks to your system at a later date, remember to move the

terminator from its old location to the new end of the bus.

I/O Bus Terminators are not used to provide impedance matching. They are

simply pull-up resistors that are used to improve the rise time of the open

collector I/O bus signals. For that reason, in some instances (e.g., a system

with both maxPAC and 564-style I/O connected with long cable runs), an

additional terminator at the DPU end might be required. Monitor the I/O Bus

Errors and, if your system seems to have an excessive amount, try adding the

additional terminator.

Refer to the Bus Extender Module chapter in this manual for information on

how to install terminators when BEMs are present in the system

.png)

.png)

.png)