GEExtended Product Life Cycle Support Notice Service with Updated Technology Mark* VIe I/O Packs

This Extended Product Life Cycle Support Notice is intended to help you plan the maintenance and

evolution of your Mark VIe control system. This notice, as part of a broader Product Life Cycle

Support Policy, protects your investment with extensive replacement parts availability, typically

extending up to 10 years following the end of production date, including planned upgrade paths to

current control technologies.

At inception, Mark VIe controls embraced the principle of extended life cycle through an Ethernet

backbone design with discrete modular building blocks, including controllers, network components,

I/O modules, and extensive software tools. This flexible, modular, upgradeable architecture enables

our customers to maintain a state-of-the-art control system by upgrading or replacing components

as needed. This design allows for incremental technology upgrades, obsolescence protection, parts

life cycle planning and comprehensive system upgrades, without the need to replace the entire

control system.

The electronics technology for the Mark VIe I/O packs introduced in 2004 is obsolete, and updated

electronics technology was introduced in 2010. The updated Mark VIe I/O packs are

backward-compatible, and can be mixed and matched with the older technology including in TMR

systems.

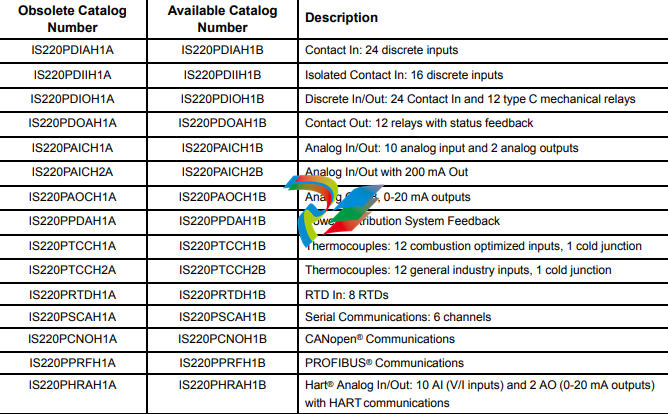

Effective February 1, 2015, GEIP will offer only the updated technology I/O packs as indicated on the

following chart.

Obsolete Catalog

Number

Available Catalog

Number Description

IS220PCAAH1A IS220PCAAH1B Core Analog In/Out for heavy duty gas turbines

IS220PCLAH1A IS220PCLAH1B Core Analog In/Out for aero-derivative turbines

IS220PSVOH1A IS220PSVOH1B Servo Control: 2 outputs, 8 LVDTand 2 pulse rate inputs

IS220PTURH1A IS220PTURH1B Turbine In/Out: Primary Turbine protection

IS220PPRAS1A-HIA IS220PPRAS1B Turbine In/Out: Turbine Backup Protection

IS220PPROH1A IS220PPROS1B Turbine In/Out: Turbine Backup Protection

Not applicable IS215AEPCH2F AEPC - 30Nm non-CANBus Wind Pitch Control (Center/Axis)

IS215AEPCH1C IS215AEPCH1F AEPC - 30Nm Wind Pitch Control (Center/Axis)

IS215AEPCH1A IS215AEPCH1D AEPC -20Nm Non-ESS Wind Pitch Center Control

IS215AEPCH1B IS215AEPCH1E AEPC - 20Nm ESS Wind Pitch Center Control

IS215AEPAH1A IS215AEPAH1C AEPA - 20Nm Wind Pitch Axis Control

IS215WEPAH1A IS215WEPAH1B WEPA - 30Nm CANBus Wind Pitch Axis Control

IS215WEPAH2A IS215WEPAH2B WEPA - 30Nm non-CANBus Wind Pitch Axis Control

IS215WETAH1B IS215WETAH1CA WETA - Wind Topbox A Module

IS215WEMAH1A IS215WEMAH1BA WEMA -Wind Energy Main Cabinet “A” (DTA)

To ensure ease of service with this updated I/O technology, some preparation work may be

required during your next outage. The level of preparation depends on the revision level of your

site’s hardware and software.The preparation details are included in the service procedure:

GEI-100847, BPPC I/O Upgrade V05.01.03 Instruction Guide. The following chart summarizes the

required actions:

ControlST Version Required Action During Next Plant Outage

ControlST* V04.04 or later Install BPPC I/O Upgrade V05.01.03 across the system

Prior to ControlST V04.04 1. Upgrade to ControlST V04.07.08C or ControlST V05.02.04C, or the highest

available version at the next scheduled outage.

2. Install BPPC I/O Upgrade V05.01.03 across the system

Prior to ControlST V03.06 Contact GE for support

GE is committed to cost-effective, life-cycle support, and offers a wide range of hardware and

software product, services, and service agreements to keep your equipment running reliably. For

further assistance, contact the nearest GE Sales or Service Office, or an authorized GE Sales

Representative.

Robert Ridgway

Mark VIe Controls Platform Product Line Manager

GE Intelligent Platforms