Tech-note ptn0322-4.doc - 19.09.2012 UniOP eTOP413 1 UniOP eTOP413

The UniOP eTOP Series 400 HMI products combine state-of-the-art features and top performance

with an oustanding design. They are the ideal choice for all demanding HMI applications including

factory and building automation.

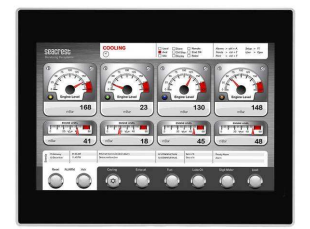

The eTOP413 features an industry standard 13.3” TFT display with WXGA resolution and full vector

graphic capabilities. The JMobile software offers full vector graphic capabilities and plenty of

connectivity options.

• 13.3” TFT color display, CCFL backlight

• 1280x800 pixel (WXGA) resolution, 64K colors

• Advanced vector graphics

• Resistive touchscreen

• 64 MB user memory

• 10/100 Ethernet interface

• USB interface

• Connection to bus systems using optional

plug-in modules

• Slim design. Mounting depth less than 50mm

• JMobile runtime included

The eTOP Series 400 HMI panels have been designed to run the JMobile software.

• JMobile runtime included. Full

compatibility with JMobile Studio.

• Full vector graphic support. Native support

of SVG graphic objects. Trasparency and

alpha blending.

• Full object dynamics: control visibility and

transparency, move, resize, rotate any

object on screen. Change properties of

basic and complex objects.

• TrueType fonts

• Multilanguage applications. Easily create

and manage your applications in multiple

languages to meet global requirements.

Far East languages are supported. Tools

available in JMobile Studio support easy

third-party translations and help reducing

development and maintenance costs of

the application

• Data display in numerical, text, bargraph,

analog gauges and graphic image

formats.

• Rich set of state-of-the-art HMI features:

data acquisition, alarm handling,

scheduler and timed actions (daily and

weekly schedulers, exception dates),

recipes, users and passwords, e-mail and

RSS feeds, rotating menus

• Includes support for a wide range of

communication drivers for Factory and

Building Automation systems.

• Multiple drivers communication capability.

• Remote monitoring and control. ClientServer functionality. Mobile clients

supported.

• Off-line and On-line simulation with

JMobile Studio.

• Powerful scripting language for

automating HMI applications. Script

debugging improves efficiency in

application development.

• Rich gallery of symbols and objects

• Project & page templates

• Optional plug-in modules for fieldbus

systems, networks and controllers.

Compatible with TCM and SCM modules.

Display

Type TFT

Resolution 1280x800, WXGA

Active display area 13.3” diagonal

Colors 64K

Backlight CCFL

Brightness 250 Cd/m2

typ.

Dimming Yes

System Resources

Operating System Windows Embedded CE 6.0

User memory 128 MB Flash

RAM 256 MB DDR2

Operator Interface

Touchscreen Analog resistive

User LED indicators 1

System LED indicators 4

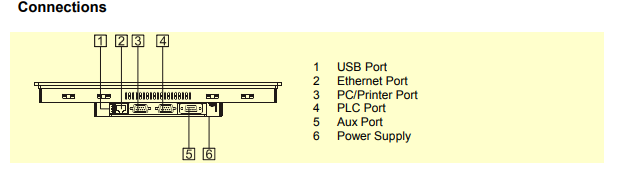

Interfaces

Ethernet port 10/100 Mbit

USB port Host interface, version 2.0

Serial Port 1 RS-232, RS-485, RS-422,

software configurable

Serial Port 2 RS-232, RS-485, RS-422,

software configurable

Aux port Yes, optional fieldbus and

controller modules

Functionality

Vector graphics Yes, includes SVG support

Object dynamics Yes. Visibility, position, size,

rotation for most object types.

TrueType fonts Yes

Multiple driver

communication

Yes, max 2 drivers

Data acquisition and

trend presentation

Yes. Flash memory storage

limited only by available

memory

Multilanguage Yes, with runtime language

switching.

Recipes Yes. Flash memory storage

limited only by available

memory

Alarms Yes

Historical event list Yes

Users and passwords Yes

Hardware Real Time

Clock

Yes, with battery back-up

Screen saver Yes

Buzzer Yes, audible feedback for

touchscreen

Ratings

Power supply voltage 24 Vdc (18 to 30 Vdc)

Current consumption 1.1 A at 24 Vdc(max.)

Fuse Automatic

Weight Approx 2.8 Kg

Battery Rechargeable Lithium battery,

not user-replaceable

Environmental

Conditions

Operating temperature 0 to 50 °C (vertical

installationmounting)

Storage temperature -20 to +70 °C

Operating and storage

humidity

5 – 85 % relative humidity,

non-condensing

Protection class IP66 (front panel)

IP20 (rear)

Dimensions

Faceplate LxH 337x267 mm

Cutout AxB 326x256 mm

Depth D+T 42mm+4mm

Approvals

CE Emission

EN 61000-6-4

Immunity

EN 61000-6-2

for installation in industrial

environments

UL UL508 Listed