rolls-royce User Manual Rolls-Royce Helicon X3 P&T Control System

Purpose

The purpose of the Helicon X3 User Manual is to provide the necessary information to

plan and perform a safe and correct operation of the installed delivered system, as well

as under-standing the basic functionality of the equipment. The User Manual covers

both operational and technical aspects of the system.

The personnel involved in using the system must have relevant experience and training

with regards to the use of such systems.

2 Warranty

The product has a limited warranty. Please note that the warranty will be void if the

equipment is misused or not handled in accordance to prescribed standards, for example

dismantling the equipment to a level greater than described.

3 Contents

This manual contains the following chapters:

Chapter Contents

1. Introduction This chapter specifies the purpose and target groups for the

manual. It also contains list of used abbreviations and a

specification of the document conventions.

2. Safety This chapter specifies safety instructions to follow when

operating and maintaining system.

3. System Description This chapter briefly describes the system components, the

system design and the functionality.

4. Delivery Specification This chapter specifies the delivered equipment.

5. Technical Data This chapter contains technical specifications and

performance data.

6. Operating Instructions This chapter describes how to use the Helicon X3 system.

7. Maintenance Instructions This chapter describes how to maintain the Helicon X3

system, including both preventive and corrective actions.

8. Trouble Shooting This chapter describes how to act when a malfunction occur

in the Helicon X3 system.

9. Contact Information This chapter contains contact information for Rolls-Royce

Marine, Dept. Propulsion Ulsteinvik and Rolls-Royce World

Wide Support Organization.

10. Spare Parts This chapter specifies recommended spare parts for the

Helicon X3 system.

11. Tools This chapter describes required and recommended tools for

the maintenance of the system to use during the installation.

12. Design Drawings This chapter consists of design drawings that serve as an

information source about the installed system for the

installation.

13. Revision This chapter contains the revision history for the total binder.

14. Subsuppliers Manuals This chapter contains documentation from other suppliers

than Rolls-Royce, if such has been delivered by RRM.

Target Groups

The User Manual is primarily intended for the user of the system. The user must be

properly trained in using and maintaining the system.

The installation of the system components must be made by yard mechanics with

experience in fitting marine electronic equipment. Cabling into the units, wire

termination and screen/shield termination should be made by yard electricians that have

a certificate of apprenticeship or equal qualification on ship electrical installation.

Commissioning and testing must be carried out by field service personnel from RollsRoyce Marine, Dept. Propulsion Ulsteinvik or qualified service engineers from RollsRoyce Marine Global Support Network (GSN).

5 Terms and Abbreviations

Abbreviation or term Description

AC/DC Alternating Current/ Direct Current

AQM Aquamaster

AZP Azipull Thruster

BC Backup Control

CAN Controller Area Network

CCW Counter Clock Wise

CW Clock Wise

DC/DC Direct Current/ Direct Current

ESD Electrostatic Discharge

EU European Union

GSN Global Support Network

GUI Graphical User Interface

I/O Input/Output

LCD Liquid Crystal Display

LED Light Emitting Diode

MP Main Propulsion

NC Normally Closed

PMS Power Management System

PTI Power Take In

PTO Power Take Out

RC Remote Control

RPM Revolutions Per Minute

RR Rolls-Royce

RRM Rolls-Royce Marine

RUP Running Up/Down Program

SAT Sea Trial Acceptance Test

STBD Starboard

TCNS Thruster Compass Nozzle Swing-Up

TT Tunnel Thruster

V Volt

Introduction

This chapter provides information regarding safety precautions that must be taken to

prevent injury to people and damage to equipment.

Whoever is responsible for the installation, operation or maintenance of this RollsRoyce system, is obliged to read this chapter and fully understand its content before any

installation, operation or maintenance of the system may take place.

2 Disclaimer

Undertaking any work envisaged by this document may either directly or indirectly

create risks to the safety and health of the person undertaking the work or the product

and/or its components while the work is being performed.

It is the responsibility of the user to protect the health and safety of the persons

undertaking the work as well as risk to the product and/or its components. Therefore the

user must ensure that appropriate controls and precautions are identified and taken in

relation to the work envisaged by this document in accordance with the relevant

statutory and legal and industrial requirements.

Neither this document, nor its use, in any way absolves the user from the responsibility

to ensure that the controls and precautions referred to above are implemented.

If any Rolls-Royce product design related features which could create risks to persons,

the product and/or its components are identified, Rolls-Royce should be contacted

immediately.

It is the user's responsibility to make all relevant hazard identifications and risk

assessments of all the activities associated with the use of this document.

It is the user's responsibility to design and implement safe systems of work and to supply

safe equipment (including, without limitation, safety equipment) and training

(including, without limitation, health and safety training) to anyone using this document

to work on products to which it relates.

A user without relevant experience of working in accordance with this document, or

with products to which it relates, should seek appropriate advice to identify the health

and safety controls and precautions that need to be taken while working.

Technical assistance can be sought from Rolls-Royce and will be subject to RollsRoyce's terms and conditions.

3 Safety Instructions

This Rolls-Royce system is a remote control system that is controlling propulsion units

on the vessel. By operating the system, the thrusts direction and pitch/speed

performance can be controlled.

The operator must at all times be aware of:

• Consequences of operating the system to prevent injury to people, damage of

equipment, damage to the vessel operated and damage to the surroundings.

3.1 Safety Functions

A number of safety functions are included in the system. These functions will become

operative if a failure should occur in the propeller control system itself, or in external

systems connected to the propeller control system.

Note: The backup control system has only interface to the control levers. The

backup control system does not have interface to external control

systems like Dynpos, Joystick or Autopilot

Note: No azimuth restrictions or load control functions are included in the

backup system. When operating using the backup system, the operator

must be careful not to overload the engine or the propeller system. If a

load control system is included in the Rpm Drive, this will still be in

operation.

Note: The safety functions described underneath will only be available if the

thruster(s)/gear(s) have got the described function in the first place.

3.1.1 Pitch Control

The pitch control is one of the redundant functions in the control system. The backup

control system will automatically be engaged if a serious failure occurs in the normal

control system. This includes loss of power supply to the normal control system, halt in

the normal control cpu, failure on the normal control order potentiometer in the lever on

the manoeuvre station currently in command, failure on the normal control field bus and

failure on the normal control feedback potentiometer. Alarm will be given in the control

system and in the ship's alarm system.

3.1.2 RPM Control Electric Engine

The RPM control is a redundant function in the control system. The backup control

system will automatically be engaged if a serious failure occurs in the normal control

system. This includes loss of power supply to the normal control system, halt in the

normal control cpu, failure on the normal control order potentiometer in the lever on the

manoeuvre station currently in command and failure on the normal control field bus.

Alarm will be given in the control system and in the ship's alarm system.

3.1.3 Azimuth Control

The azimuth control is a redundant function in the control system. The backup control

system will automatically be engaged if a serious failure occurs in the normal control

system. This includes loss of power supply to the normal control system, halt in the

normal control cpu, failure on the normal control order potentiometer in the lever on the

manoeuvre station currently in command, failure on the normal control field bus and

failure on the normal control feedback potentiometer. Alarm will be given in the control

system and in the ship's alarm system.

3.1.4 Dynpos and Joystick

If operating using an external Dynpos or Joystick system and a failure occurs either on

the pitch order, the rpm order or the azimuth order signal from the external system, the

external system is disengaged and the propeller responds to the control lever order on

the manoeuvre station in command. Alarm will be given in the control system and in the

ship's alarm system.

3.1.5 Autopilot

If operating using an external autopilot system and the azimuth lever order on the

manoeuvre station in command is changed more than the adjustable limit, normally 20

degrees, the autopilot is disengaged and the thruster will respond to the control lever.

This is indicated by blinking the Autopilot button, and the buzzer will sound until the

Autopilot button is pressed to acknowledge the mode change back to lever control.

Safety Messages

Safety messages in this manual are always accompanied by a safety alert symbol and a

signal word. The safety alert symbol is used to alert the reader about a potential risk of

personal injury or damage to the equipment.

The following types of safety messages are used within this manual:

Warning: Risk of... Indicates the presence of a hazard which could result in death or

personal injury.

Caution: Indicates the presence of a hazard which could result in damage to

equipment or property and seriously impact the function of the equipment.

Note: Alerts the reader to relevant factors and conditions which may impact the

function of the equipment.

General

This chapter provides an overview of the Helicon X3 system and a technical description

of the main components that give the required knowledge about the system.The figures,

drawings and text in this chapter are general and may not comply to the actual

installation on the vessel. For details on the delivered equipment, see chapter 4 Delivery

Specification.

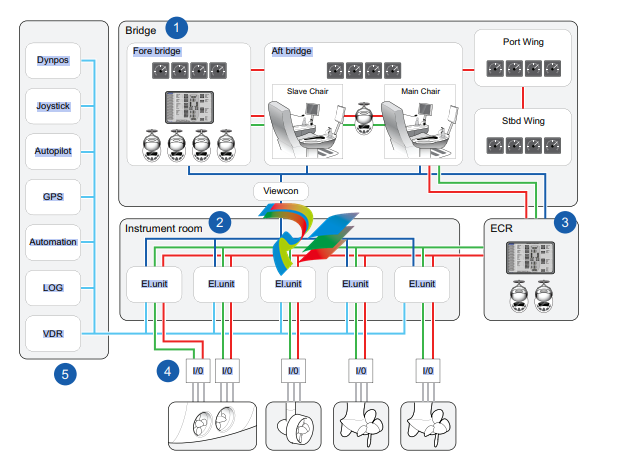

2 System Overview

The Helicon X3 remote control system is a micro-processor-based system, controlling

the propulsion units on the vessel. The following main functions are included:

• Combinator control, allowing accurate and reliable control of the propeller pitch and

motor speed (RPM). The combinator curve optimises the pitch/speed performance to

give the best operational conditions and fuel economy.

• Pitch control, allowing accurate and reliable control of the thruster pitch.

• Speed control, allowing accurate and reliable control of the motor speed (RPM).

• Direction control, allowing accurate and reliable control of the thrust direction.

• Follow-up backup control from control levers.

Helicon X3 consists of the following main components:

• Instruments, screens, levers and Viewcon on the bridge (1).

• Electrical cabinets in the instrument room (2) and thruster room (4).

• Instruments, screens and levers in the engine control room (3).

Helicon X3 may interface several external systems (5), like Dynamic positioning

systems and Autopilots.

Design

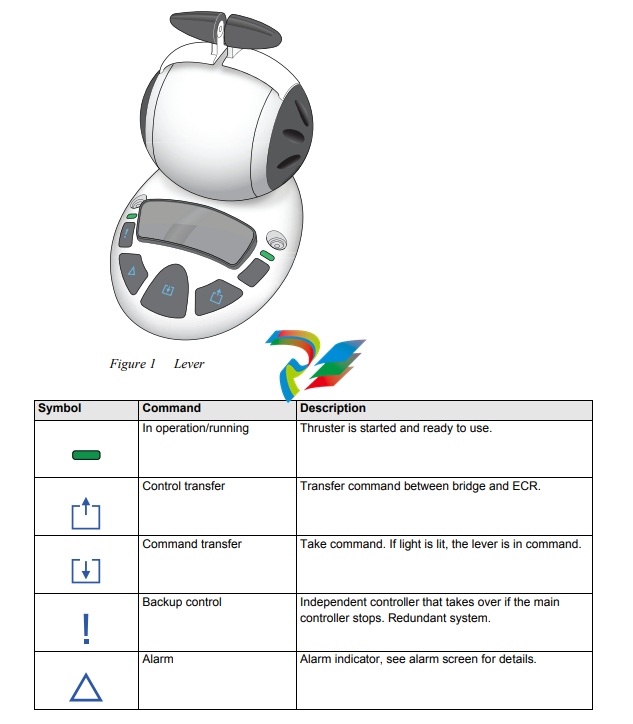

3.1 Lever

Each thruster has its own lever. Their main functions are:

• Control of pitch, RPM and azimuth direction (dependant of application)

• In operation

• Command transfer

• Lever in command

• Back-up control

• Alarm

The control lever has integrated buttons and indication lamps for command transfer,

backup system on/off, alarm indication/buzzer and push button for reset of buzzer. The

display in the base shows set command (pitch and direction) from the lever.

The lever contains two redundant electronic circuits, one for the normal control system

and one for the backup system.

Control Panel

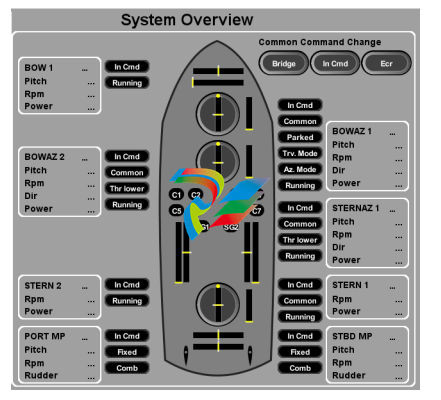

The control panel (touch screen) is the main user interface for the operator and gives an

overview of all the thrusters on the vessel. It shows the status of the system, indicates

thruster forces, displays alarms, and shows selected modes. The flat button on the top of

the screen is for dimming the illumination of the LCD display.

The screen is divided in two areas: a menu area in the left part of the screen, and a bigger

command area to the right. The menu buttons to the left selects the content of the

command area.

There is one command page for each thruster, in addition to one system overview page

and one alarm page. The overview page shows the most essential information for all

thrusters, but to activate functions or to view all available information for a thruster, the

particular thrusters' page must be selected.

The graphical design is based on the following principles:

• All functions pages are only one click away

• Large and simple buttons which are easy to read.

• Same design theme for all clickable objects.

• To avoid unintentional activation of functions, all function activation buttons require

press on the accept button to proceed.

Colour on button Function

A ring around the button The button is push able

Blue Indicates current status

Green Start

Red Stop

2 buttons flashing Select function

1 button flashing The button has been activated and will flash until the function

has started/stopped

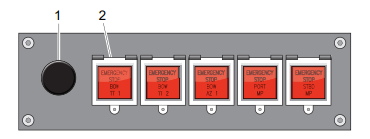

Emergency stop and dimmer panel (optional)

The emergency stop is used to shut down the thrusters immediately.

There is one button per thruster unit.

The wheel (1) is used for dimming the background light on the indicators situated on the

same control station.

The dimmer may be delivered in a separate panel, if the emergency stop buttons are not

part of the delivery scope.

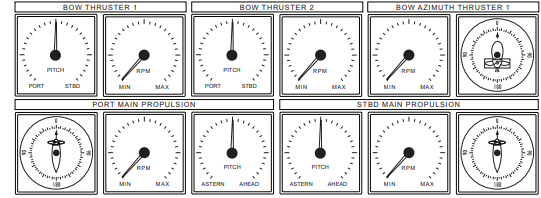

Indicators

The indicators give feedback on various data and can be found on the bridge and in the

engine control room.

There are three main types of indicators:

• Azimuth indicator

• RPM indicator

• Pitch indicator

In addition a bridge order indicator may be delivered on some vessels.

Viewcon

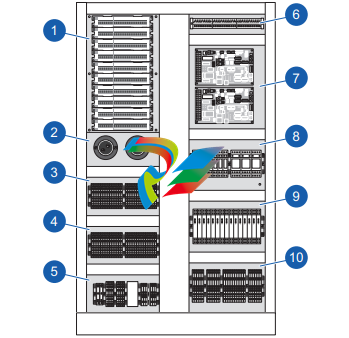

Network cabinet

The network cabinet(s) contains several switches. The network cabinet(s) connects the

panel PCs and the controller cabinets.

Network

Operator stations and electronic units are linked together in an Ethernet network. The

network is single and may contain several separate switches.

(CAN bus is the internal communication between levers, I/O modules and Marine

Controller.)

1. Rolls-Royce Marine Controller (Normal)

2. Rolls-Royce Marine Controller (Backup)

3. I/O modules

4. Power distribution

5. Network switches and terminals

6. Signal isolation amplifiers (optional)

7. Power Distribution

8. Main power supply (AC) / fuses

9. Backup power supply (DC) / fuses

3.7 I/O Cabinet

The I/O cabinet is often located in the thruster room near sensors and actuators. This

cabinet distributes signals to the different propulsion/thruster units. There is one I/O unit

per propeller/thruster.

The I/O cabinet sends signals to the actuators on the propellers/thrusters and receives

signals from the sensors. There is CAN bus communication between each I/O and

controller cabinet.

Normal Control

The output from the pitch controller is computed on the basis of the input signals from

pitch lever and the actuator position feedback.

Lever and feedback signals are scaled and checked against adjustable limits, with

corresponding alarm for exceeding the normal range. The levers have one set of

adjustments (minimum, zero and maximum) for each manoeuvre station. Multiple sets

of feedback adjustments (minimum, zero and maximum) are available for various

engine power take-outs.

In combined mode the lever signal is modified in a Combinator program, see chapter

Pitch and RPM Combinatory (combined Control).

4.1.2 Backup Control

The Backup Control system consists of closed loop control identical to the Normal

Control system. The Backup Control is a separate system, and is independent of the

Normal Control system. A system failure in the Normal Control system will

automatically switch to and engage the Backup Control.

Lever order signals and feedback are monitored and verified against adjustable alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant and

both visual and audible system failure alarm will be actuated at the manoeuvre stations.

4.1.3 Backup Control Operation

If a failure occurs on important parts of the Normal Control for the Pitch, Azimuth or

RPM Control function, the control will automatically be switched over to the Backup

Control system. A system failure audible and visible alarm will be activated on each of

the control panels.

The thruster control will continue to follow the lever in command and transfer is done

by using the common in command buttons. The command can be transferred between

all bridge position and the bridge control levers will continue to work as in normal

control.

A failure that occurs on important parts of the Backup Control for the Pitch, Azimuth or

RPM Control function will not affect the Normal Control system. If a system failure

occurs on the Backup Control an audible and visible alarm will be activated on each of

the control panels.

4.1.4 Backup Control Limitations

The Backup Control system has only interface to the control levers. The Backup Control

system does not have interface to External Control systems like Dynamic positioning

systems, Joysticks or Autopilots.

No pitch reduction or load function are included in the Backup system.

When operating using the backup system, the operator must be careful not to overload

the engine or the propeller system.

4.1.5 Local Control

If both the Remote Control system and the Backup Control should fail it is possible to

operate the propeller pitch locally from the pitch control valve.

4.1.6 Pitch Indication

The Pitch Indication system is independent of the Normal Pitch Control system by

means of separate transmitters and electronic circuits. The pitch indicators are connected

in series and are driven from the Backup Control system.

4.1.7 Pitch Order Scaling

The system may need to reduce the pitch order for different reasons. The pitch reduction

can either be activated from a digital or anlogue input signal.

To reserve engine power to heavy consumers as alternators, fire pumps, etc., it may be

necessary to reduce the available propeller output power. This is normally done by

means of a fixed propeller pitch reduction.

If the drive motor is a diesel engine the system is prepared to handle a fuel limiter

contact, from the RPM governor (i.e. high scavange air pressure). If the contact is closed

the pitch order will stop increasing to a higher value, only decrease of pitch order against

zero is possible.

For azimuth thrusters, a pitch reduction will be activated if the azimuth order is changed

faster then the thruster azimuth servo can follow.

4.2 Thruster Azimuth Control

The azimuth control function is to obtain the correct thruster azimuth position in

accordance to the control lever order. Valve controlled hydraulic motors or frequency

controlled electro motors perform the positioning of the thruster azimuth.

Detailed information regarding the hydraulic system or motor data is available in the

Thruster Instruction manual.

Note: Test point angle signals are ranged +/- 100%, representing +/- 180 degrees.

Some test points are named with degrees, displaying the angle in degrees

(+/- 180 degrees).

4.2.1 Normal Control

The azimuth controller computes the thruster position and order on the basis of signals

from the thruster feedback and control levers. A two-wiper linear potentiometer

provides two outputs with 90 degrees of phase shift named cosine and sine phase

respectively.

The lever order signals and feedback signals are monitored and verified against alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant with

a visual and audible system failure alarm on the manoeuvre stations.

4.2.2 Backup Control

The Backup Control system consists of closed loop control identical to the normal

control system. The Backup Control is a separate system, and is independent of the

Normal Control system. A system failure in the Normal Control system will

automatically switch to and engage the Backup Control.

Lever order signals and feedback are monitored and verified against adjustable alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant with

a visual and audible system failure alarm on the manoeuvre stations.

4.2.3 Backup Control Operation

If a failure occurs on important parts of the Normal control for the Pitch/Azimuth/RPM

control function, the control will automatically be switched over to the backup control

system. A system failure audible and visible alarm will be activated on each of the

control panels.

The thruster control will continue to follow the lever in command, and command

transfer is done by using the common in command buttons. The command can be

transferred between all bridge position and the bridge control levers will continue to

work as in Normal Control.

A failure that occurs on important parts of the Backup control for the Pitch/Azimuth/

RPM control function, will not affect the Normal control system. If a system failure

occurs on the Backup Control an audible and visible alarm will be activated on each of

the control panels.

4.2.4 Backup Control Limitations

The backup control system has only interface to the control levers. The backup control

system does not have interface to external control systems like Dynpos, Joystick or

Autopilot.

Note: No azimuth restrictions or load control functions are included in the

backup system.

When operating using the backup system, the operator must be careful not to overload

the engine or the propeller system.

4.2.5 Local Control

Local control is used if both the normal control and the backup control fail to operate the

thruster azimuth. The thruster azimuth can be operated locally on the actuator unit. The

Control System must first be disconnected from the actuator unit. This can be done by

means of the Local Control switch mounted in front of the Actuator Interface Unit, or

by disconnecting the plug from the actuator unit. If frequency converter used, operate

service switch inside converter cabinet.

The Thruster Instruction Manual will give more details for Local Control operation.

4.2.6 Azimuth Indication

The azimuth indication system independent of the normal control system by means of

separate transmitters and electronic circuits. The Azimuth indicators are connected in

series, and are driven from the Backup Control system.

RPM Control

The RPM Control function system controls the speed signal to the frequency converter

for electrical drives or the engine governor for diesel or gas engines.

4.3.1 RPM Control Electric Drive Motor

The RPM Control system includes selection of different operational modes:

• Separate Mode

• Combined Mode

Selection between modes is possible by means of push buttons. RPM Control can be

managed from engine control room only or from additional control panels.

4.3.2 External RPM Control

External RPM order signals from system as DP/Joystick/Auxiliary systems can be

connected to the rpm controller.

The external rpm signal are checked against adjustable preset limits. Any error

conditions on the rpm input signal will initiate a warning to the alarm plant and an error

message will be displayed on the control panel.

4.3.3 RPM Order Output

The output signal from the controller is scaled to meet the actuator signal range from idle

to full rpm, and then fed to external governor, IP converter or frequency converter. The

output will follow a linear curve between idle and full rpm order.

The RPM output rate of change is adjustable and can be adapted to the engine/frequency

converter reversing speed from idle to full rpm (increasing order) and vice versa

(decreasing order).

4.3.4 Propeller/Shaft RPM Indication

The propeller/shaft RPM indicators are connected in series and are driven from the

Backup Control system.

4.4 Command Transfer

The term Command transfer is used to describe the procedure performed when the

control is transferred between manoeuvre stations without acceptance on either of the

stations. This is normally the procedure between wheelhouse (bridge) stations.

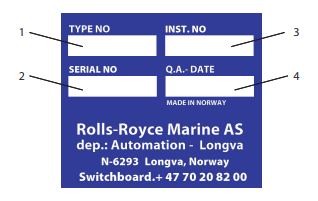

5 Location of Manufacturing Number

5.1 Marking Locations

Electrical cabinets and junction boxes are physically marked with a unique tag, and also

on all applicable drawings. The I/O cabinets are marked with the Rolls-Royce logotype

in the upper left corner.

The Rolls-Royce logotype is imprinted in remote control panels, alarm panels and cabin

panels.

Cables are marked with a cable tag at both ends.

5.1.1 Company Identification

The Rolls-Royce Company Identification sticker shows where the product has been

produced and is found on discrete places on all delivered items, e.g. on the inside of the

cabinet doors.

Pos Denomination Meaning

1 TYPE NO Corresponding drawing number with the revision letter in

closed brackets

2 SERIAL NO Production order number

3 INST. NO Installation number

4 Q.A. DATE Date and signature by test responsible

Technical Specification

Propulsion & Thruster Control System

Project no. : 20-12-00136

Version : -

Vessel type (design) : UT535E

Customer Project no. : RRM STO – P12/7210

Shipowner :

Shipyard :

Yard no. :

Rolls-Royce Marine

Propulsion Ulstein Unit nos : 2xTT CP (bow), 2xUS FP (main)

.png)

.png)

.png)