Vibro-meterGSI127 galvanic separation unit

KEY FEATURES AND BENEFITS

• From the vibro-meter ® product line

• Power supply for sensors and/or signal

conditioners with a current output or a

voltage output

• 4 kVRMS galvanic separation between the

sensor side and the monitor side

• 50 VRMS galvanic separation between the

power supply and the output signal

(floating output)

• High rejection of frame voltage

• μA to mV transfer function for current-signal

transmission over longer distances

• V to V transfer function for voltage-signal

transmission over shorter distances

• Available in standard versions and Ex versions

certified for use in potentially explosive

atmospheres (hazardous areas)

• Compatible with all vibro-meter

sensors / measurement chains

• Also compatible with industry-standard IEPE

sensors and 4 to 20 mA loop-powered sensors,

including vibration sensors/transmitters

• No ground connection needed

KEY BENEFITS AND FEATURES (cont’d)

• Suitable for use in functional safety contexts:

SIL 2 in accordance with IEC 61508

• Removable screw-terminal connectors

• DIN-rail mounting

APPLICATIONS

• All vibro-meter sensors / measurement chains

• Safety-related applications

DESCRIPTION

The GSI127 is a galvanic separation unit from

Parker Meggitt’s vibro-meter ® product line. It is

designed for operation with the signal conditioners,

charge amplifiers and electronics (attached or

integrated) used by various vibro-meter

measurement chains and/or sensors.

Compatible devices include the IPC707 signal

conditioners (charge amplifiers) used by CAxxx

piezoelectric accelerometers and CPxxx dynamic

pressure sensors (and older IPC704 signal

conditioners), the IQS9xx signal conditioners used by

TQ9xx proximity sensors (and older IQS4xx signal …

Information contained in this document may be subject to export control regulations of the European Union, USA or other countries. Each

recipient of this document is responsible for ensuring that the transfer or use of any information contained in this document complies with all

relevant export control regulations. ECN N/A.

DESCRIPTION (continued)

conditioners), the attached or integrated electronics

used by CExxx piezoelectric accelerometers, and the

integrated electronics used by the VE210 velocity

sensor. The GSI127 is also compatible with industrystandard IEPE (integrated electronics piezo electric)

sensors such as the CE620, CE630 and PV660

vibration sensors, and 4 to 20 mA loop-powered

sensors such as the CE687 and PV685 vibration

sensors.

Note: The variant of the GSI127 defined by the

ordering option code B11 is compatible with IQS91x

signal conditioners and/or industry-standard

4 to 20 mA loop-powered sensors/transmitters.

The GSI127 galvanic separation unit is a versatile unit

that can be used for the transmission of highfrequency AC signals over long distances in

measurement chains using current-signal

transmission or as a safety barrier unit in

measurement chains using voltage-signal

transmission. More generally, it may be used to

supply any electronic system (sensor side) having a

consumption of up to 21 mA.

The GSI127 also rejects a large amount of the frame

voltage that can introduce noise into a measurement

chain. (Frame voltage is the ground noise and AC

noise pickup that can occur between the sensor case

(sensor ground) and the monitoring system

(electronic ground)). In addition, the design of its

internal power supply results in a floating output

signal, thereby eliminating the need for an additional

external power supply such as a APF19x.

Ex versions of the GSI127 are certified to be installed

in an Ex Zone 2 (“Ex ec”) when supplying

measurement chains installed in Ex environments up

to Zone 0 (“[ ia Ga ]”). These units can also eliminate

the need for additional external Zener barriers.

The GSI127 housing features removable screwterminal connectors that can unplugged from the

main body of the housing to simplify installation and

mounting. It also features a DIN-rail mounting

adaptor for direct mounting on a DIN rail.

In addition, the GSI127 incorporates diagnostics that

automatically and remotely indicates the health/

status of the measurement chain so you always know

when measurements can be trusted. The diagnostics

(SIL 2 “by design”) bring enhanced reliability and

significant risk reduction, making the GSI127 suitable

for use in safety-related applications (functional

safety contexts).

For specific applications, contact your local

Parker Meggitt representative.

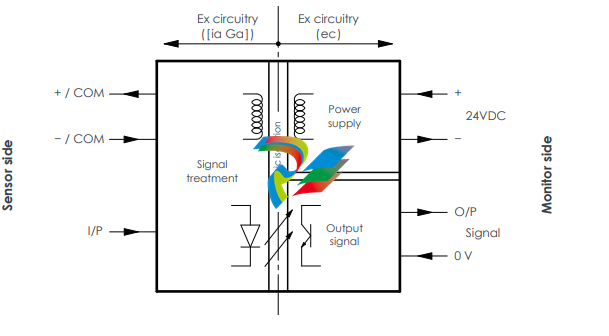

BLOCK DIAGRAM

SPECIFICATIONS

Environmental

General

Temperature

• Operating : −20 to 70°C (−4 to 158°F)

• Storage : −40 to 85°C (−40 to 185°F)

Humidity

• Operating : 90% max. non-condensing

• Storage : 95% max. non-condensing

Protection rating

(according to IEC 60529)

: IP20.

Note: The GSI127 is suitable for indoor use only unless it is installed in

an industrial housing or enclosure that ensures a higher level of

environmental protection.

Vibration

(according to IEC 60068-2-6)

: 2 g peak above resonant frequency and 0.35 mm peak below

(10 to 55 Hz, 6 hours/axis)

Shock acceleration

(according to IEC 60068-2-27)

: 15 g peak

(half sine impulse, 11 ms duration, 3 shocks/axis)

Altitude : 4000 m (13100 ft) max.

Note: Reduced air density affects cooling ability.

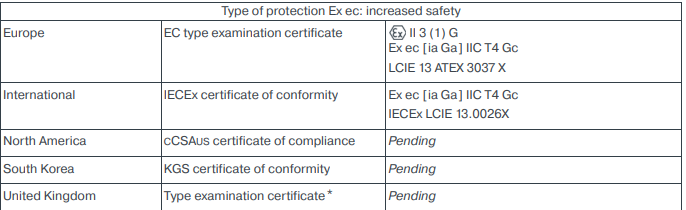

Potentially explosive atmospheres (ordering option code A2)

Available in Ex approved versions for use in hazardous areas

*UKCA marking is not engraved/marked on the product.

For specific parameters of the mode of protection concerned and special conditions for safe use,

refer to the Ex certificates that are available from Parker Meggitt.

When using protection mode “Ex ec” (increased safety), the user must ensure that the GSI127 is

installed in an industrial housing or enclosure that ensures a protection rating of at least IP54

(or equivalent).

For the most recent information on the Ex certifications that are applicable to this product,

refer to the Ex product register (PL-1511) document that is available from Parker Meggitt.

Note: Some certifications and approvals are pending!

SPECIFICATIONS (continued)

Approvals

Conformity : European Union (EU) declaration of conformity (CE marking)

Electromagnetic compatibility

(EMC)

: EMC compliant (2014/30/EU):

EN 61000-6-2:2005.

EN 61000-6-4:2007 + A1:2011.

Electrical safety : EN 61010-1:2010

Environmental management : RoHS compliant (2011/65/EU)

Hazardous areas : Ex approved versions

(see Potentially explosive atmospheres on page 3)

Functional safety : SIL 2 in accordance with IEC 61508

Note: Some certifications and approvals are pending!

Electrical

Power supply (to GSI127)

Input voltage range : 24 VDC nominal (20 to 28 VDC)

Power consumption : <3.1 W

Current consumption : <130 mA (with 24 VDC power supply)

Overvoltage protection : >30 VDC

Supply impedance (sensor side)

• Ordering option codes B01-B11 : <30 Ω

• Ordering option code B21 : >50 kΩ

Note: The GSI127 should be powered (energized) using a limited-power, low-voltage power supply such as a

APFxxx 24 VDC power supply or other suitable power supply unit.

In safety-related applications, a GSI127 must be powered using a limited-power, low-voltage power supply with a safe

limitation of 60 VDC (nominal), even in the event of a single fault with the power supply.

Input signal (sensor side)

Supply (to measurement chain)

• Ordering option codes B01-B03

and B11

: 20 VDC ±1 VDC / 21 to 30 mADC.

Note: 30 mADC is the maximum (short-circuit) current.

• Ordering option code B04 : 21 VDC ±1 VDC / 20 to 30 mADC.

Note: 30 mADC is the maximum (short-circuit) current.

• Ordering option code B05 : −21 VDC ±1 VDC / 20 to 30 mADC.

Note: 30 mADC is the maximum (short-circuit) current.

• Ordering option code B21 : 8 mADC ± 0.5 mADC / 22 to 30 VDC.

Note: 30 VDC is the maximum (open-circuit) voltage.

Input dynamic range

• Ordering option codes B01-B03

and B11

: 2 to 20.75 mADC

• Ordering option code B04 : 1.3 to 19 VDC

• Ordering option code B05 : −1.3 to −19 VDC

• Ordering option code B21 : 1.3 to 20.3 VDC

SPECIFICATIONS (continued)

Output signal (monitor side)

Output voltage dynamic range

(with 10 kΩ load)

: 0.8 to 20.8 VDC

Output impedance : <30 Ω, protected against short-circuits

Power supply voltage rejection ratio (PSRR)

• 10 Hz to 400 Hz : ≥60 dB

• 400 Hz to 20 kHz : ≥46 dB

Transfer characteristics

Galvanic separation

• Sensor side and monitor side : 4 kVRMS

• Power supply and output signal : 50 VRMS

Sensitivity and offset (zero)

• Ordering option code B01 : 1 V/mA and 2 VDC

• Ordering option code B02 : 1 V/mA and −5 VDC

• Ordering option code B03 : 3.2 V/mA and −48 VDC

• Ordering option code B04 : 1 V/V and 0 VDC

• Ordering option code B05 : −1 V/V and 0 VDC

• Ordering option code B11 : 0.5 V/mA and 0 VDC

• Ordering option code B21 : 1 V/V and 0 VDC

Note: See also Accuracy, Output offset and other parameters in

DC transfer on page 5, and AC transfer on page 6.

Transfer function : Output value = (Input value × Sensitivity) + Offset

Where:

Output value is the value of the analog voltage output signal from the

GSI127.

Input value is the value of the analog input signal (current or voltage) to

the GSI127.

Sensitivity is the transfer sensitivity for a particular variant of the GSI127,

as defined by the ordering option code.

Offset is the output offset for a particular variant of the GSI127,

as defined by the ordering option code.

DC transfer

Accuracy : ±1% (at ambient temperature)

Sensitivity drift : ±50 ppm/°C (over operating temperature range)

Linearity error

(best straight-line INL)

: <0.2%

Output offset

(middle of DC range)

: ±200 mVDC

Output offset drift

(middle of DC range)

: ±2 mV/°C (over operating temperature range)

SPECIFICATIONS (continued)

AC transfer

Bandwidth

• Frequency band (±0.5 dB) : DC to 20 kHz

• −3 dB cut-off frequency (typical) : 30 kHz

Accuracy : ±0.5 dB (over bandwidth from DC to 20 kHz)

Linearity error

(total harmonic distortion (THD))

: <−46 dB (0.5%) (over bandwidth from DC to 20 kHz)

Full-scale dynamic signal to noise ratio

(SNRFSD)

: >80 dB (from 10 to 2 kHz)

Connectors

Screw-terminal connector

(input, top)

: 4 contacts for sensor-side signals

Screw-terminal connector

(output, bottom)

: 4 contacts for monitor-side signals

Electrical connections

• IEC : 400 V / 0.2 to 2.5 mm2

• UL : 300 V / 10 A / 26 to 12 AWG

Clamping range (min. to max.) : 0.2 to 2.5 mm2 (26 to 12 AWG)

Tightening torque (min. to max.) : 0.4 to 0.6 N•m (0.30 to 0.44 lb-ft)

Note: The GSI127 features removal screw-terminal connectors that can unplugged from the main body of its housing to

simplify installation and mounting.

Physical

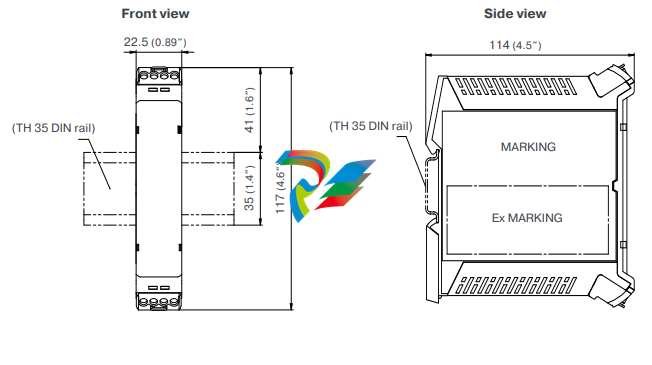

Mounting : Suitable for TH 35 DIN rails (according to EN 50022 / IEC 60715).

For example, TH 35-7.5 or TH 35-15.

Electrical connections : Removable screw-terminal connectors (see Connectors on page 6)

Housing

• Material : Polyamide (PA 66 GF 30)

• Color : Standard versions: Gray.

Ex approved versions: Gray with the electrical connections to the sensor

side indicated by blue.

Dimensions : See Mechanical drawings on page 7

Weight : 140 g (0.31 lb) approx.

MECHANICAL DRAWINGS

Notes

All dimensions are in mm (in) unless otherwise stated.

For standard versions of the GSI127, the housing is completely gray in color.

For Ex approved versions of the GSI127, the housing is gray in color but with a screw-terminal connector (top) for sensor-side signals (electrical connections) that is blue in color.

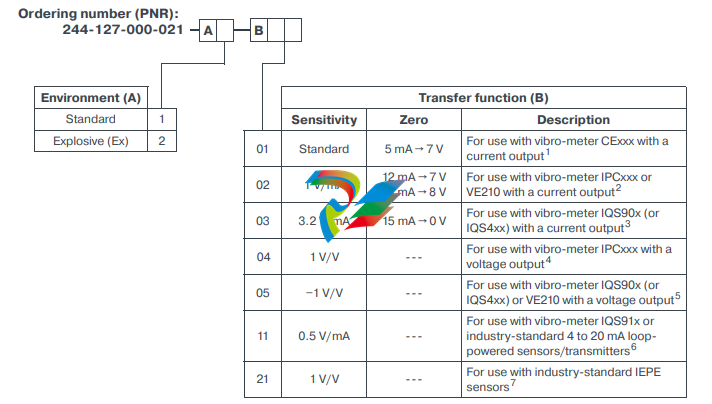

ORDERING INFORMATION

To order please specify

Type Designation Part number (PNR)

GSI127 Galvanic separation unit

Notes

1. Only CExxx piezoelectric accelerometers with a current output signal require a GSI127.

For example, CE134, CE281 and CE31x piezoelectric accelerometers.

2. A IPCxxx signal conditioner or VE210 velocity sensor with a current output signal is

typically used for signal transmission over longer distances. For example, IPC707.

Note: For a IPC707 without diagnostics, the nominal current output signal (DC) is

12 mA (→ 7 V). For a IPC707 with diagnostics, the nominal current output signal (DC) is

13 mA (→ 8 V). Refer to the IPC707 data sheet for further information.

3. A IQS90x (or IQS4xx) signal conditioner with a current output signal is typically used for

signal transmission over longer distances. For example, IQS900.

4. A IPCxxx signal conditioner with a voltage output signal is typically used for signal

transmission over shorter distances. For example, IPC707.

Note: For a IPC707 without diagnostics, the nominal voltage output signal (DC) is

7 V. For a IPC707 with diagnostics, the nominal voltage output signal (DC) is 8 V.

Refer to the IPC707 data sheet for further information.

5. A IQS90x (or IQS4xx) signal conditioner or VE210 velocity sensor with a voltage output

signal is typically used for signal transmission over shorter distances. For example,

IQS900.

6. For use with IQS910 signal conditioner (“transmitter” with a 4 to 20 mA current-loop

signal) or industry-standard 4 to 20 mA loop-powered sensors, that is, current-loop

sensors/transmitters. For example, CE687 and PV685 vibration sensors.

7. For use with industry-standard IEPE (integrated electronics piezo electric) sensors,

that is, constant-current voltage-output sensors. For example, CE620, CE630 and PV660

vibration sensors.