GESPEEDTRONIC™ MARK V STEAM TURBINE CONTROL SYSTEM

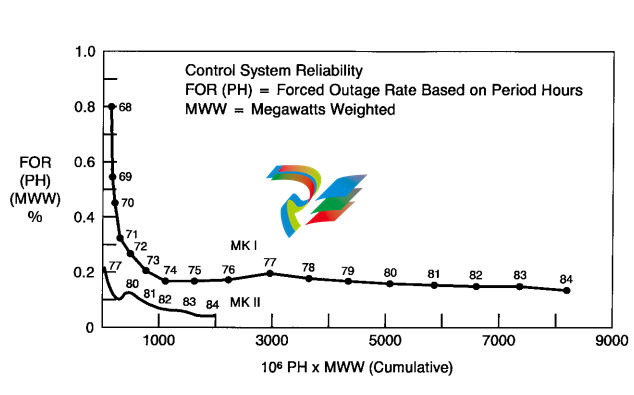

Figure 2. Control system reliability, PH is forced outage rate based on period hours; MWW is megawatt

weighted

shipped in 1987, building on gas turbine experience, including the use of many of its electronics

modules, and developing it further with Software

Implemented Fault Tolerance (SIFT). A companion single-channel system, the Mark III Plus,

aimed at the smaller industrial units, was first

shipped in 1988.

Some of the benefits from the new digital systems are flexibility and greater precision of of

the benefits from the new digital systems are flexibility and greater precision of controls because

functions are determined by software rather than

hardware, CRT operator interface, data link

interface to plant level control systems, and online repair capability for triple-redundant systems, providing further improvement in reliability.

The new SPEEDTRONIC Mark V Steam

Turbine Control System is developed from this

long evolution of electronic steam turbine controls. It is available in both triple-redundant Mark

V TMR and single-channel Mark V Simplex control systems, the only difference being the two

additional controllers in the TMR design.

STEAM TURBINE

UNIT CONTROLS

The main functions of a modern steam turbine

control system are:

• Speed and acceleration control during start-up

• Initialization of generator excitation

• Synchronization and application of load in

response to local or area generation dispatch

commands

• Pressure control of various forms: inlet,

extraction, back pressure, etc.

• Unloading and securing of the turbine

• Sequencing of the above functions under

constraint of thermal stress

• Overspeed protection during load rejection

and emergencies

• Protection against serious hazards, e.g., loss

of lube oil pressure, high exhaust temperature, high bearing vibration

• Testing of steam valves and other important

protective functions

Additional control and monitoring functions

are also required in most applications, such as:

• Monitoring and supervision of a large num

ber of pressures, temperatures, etc., to provide guidance and alarms for operators

• Start-up and monitoring of turbine-generator auxiliaries such as lube oil, hydraulic, and

steam seal systems

• Display, alarm, and recording of the above

functions and data

• Diagnosis of turbine or generator problems

• Health check and diagnostics of the electronic system itself

It is characteristic of the first group of functions

that they must be performed with high control

bandwidth, or with very high reliability, or both, to

ensure long-term reliable operation and service of

the turbine. It is for these reasons that GE has,

from the very beginning of turbine technology,

designed and provided the controls and protection for its units, starting with the MHC systems a

century ago and continuing with the new

SPEEDTRONIC Mark V control system.

For the new all-digital systems, GE has defined

the first group of functions as a “Turbine Unit

Control System." These functions, together with

the input and output devices (I/O) required, are

included in all control systems which are an integral part of steam turbines supplied by GE.

A characteristic of the unit control system is

that all essential turbine control and protection

functions are included to allow a unit to operate

safely even if other supporting systems should fail.

Another characteristic is that the “control point”

interface (i.e., the interface between the turbine

and the control system) remains in GE’s scope,

while interface to plant controls can be made at

“data point” level, which does not include critical

and rapidly varying commands and feedback signals, and therefore, is a more suitable point of

interface to possible non-GE controls. Yet another

characteristic of unit control functions is that they

must be performed either continuously or very

frequently to provide satisfactory control. Data

sampling and processing of control algorithms up

to ten times per second are used for many unit

control functions.

The second group of functions can be performed less frequently (i.e., every few seconds or

more), and turbine operation may be continued,

in most cases, during short-term interruptions in

the monitoring functions as long as the “unit control” is performing correctly.

The second group of functions includes most

of what used to be called “TSI,” for Turbine

Supervisory Instrumentation, which we now prefer to call TGM, for Turbine Generator Monitoring. The TGM functions can be included in the

Mark V systems, or they may be integrated into

the plant control system. For small- and mediumsized units, the TGM functions can be incorporated without significant extra hardware, and for

large units, additional cabinets are needed. These

cabinets can be mounted either at the turbine

and generator or in an equipment room, and they

can interface with a common Mark V operator

interface.

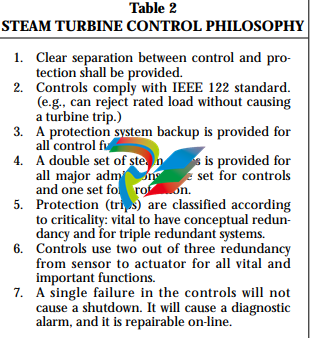

The philosophy applied to steam turbine control systems has developed over time, and it is

summarized in Table 2.

A block diagram of the protective system of the

Mark V is shown in Figure 3. The left-hand side

shows the various trip inputs entering through

redundant paths. At the extreme right is the output to the emergency trip system (ETS), a