GESPEEDTRONIC™ MARK V GAS TURBINE CONTROL SYSTEM

without overspeeding

• Critical sensors are redundant

• Control is redundant

• Alarm any control system problems

• Standardize hardware and software to enhance reliability while maintaining flexibility

Figure 2. Gas turbine fuel control

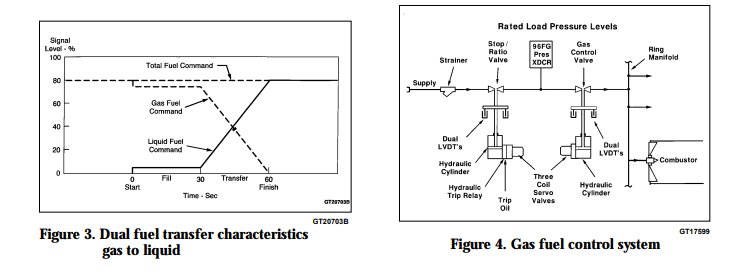

under load are accomplished by transitioning

from one system to the other after an appropriate fill time to minimize load excursions. System

characteristics during a transfer from gas to liquid fuel are illustrated in Figure 3. Purging of

the idle fuel system is automatic and continuously monitored to ensure proper operation.

Transfer can be automatically initiated on loss of

supply of the running fuel, which will be

alarmed, and will proceed to completion without operator intervention. Return to the original fuel is manually initiated.

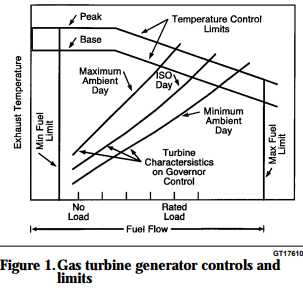

The gas fuel control system is shown schematically in Figure 4. It is a two-stage system, incorporating a pressure control proportional to

speed and a flow control proportional to fuel

command. Two stages provide a stable turndown ratio in excess of 100:1, which is more

than adequate for control under starting and

warm-up conditions, as well as maximum flow

for peak output at minimum ambient temperature. The stop/speed ratio valve also acts as an

independent stop valve. It is equipped with an

interposed, hydraulically-actuated trip relay that

can trip the valve closed independent of control

signals to the servo valve. Both the stop ratio

and control valves are hydraulically actuated,

single-acting valves that will fail to the closed

position on loss of either signal or hydraulic

pressure. Fuel distribution to the gas fuel nozzles in the multiple combustors is accomplished

by a ring manifold in conjunction with careful

control of fuel nozzle flow areas.

The liquid fuel control system is shown

schematically in Figure 5. Since the fuel pump is

a positive displacement pump, the system

achieves flow control by recirculating excess fuel