GESPEEDTRONIC™ MARK V GAS TURBINE CONTROL SYSTEM

Improvements in the new design have been

made in microprocessors, I/O capacity, SIFT

technology, diagnostics, standardization and

operator information, along with continued

application flexibility and careful design for

maintainability. SPEEDTRONIC™ Mark V control is achieving greater reliability, faster meantime-to repair and improved control system

availability than the SPEEDTRONIC™ Mark IV

applications.

As of May 1994, almost 264 Mark V systems

had entered commercial service and system

operation has exceeded 1.4 million hours. The

established Mark V level of system reliability,

including sensors and actuators, exceeds 99.9

percent, and the fleet mean-time-betweenforced-outages (MTBFO) stands at 28,000

hours. As of May 1994, there were 424 gas turbine Mark V systems and 106 steam turbine

Mark V systems shipped or on order.

CONTROL SYSTEM HISTORY

The gas turbine was introduced as an industrial and utility prime mover in the late 1940s with

initial applications in gas pipeline pumping and

utility peaking. The early control systems were

based on hydro-mechanical steam turbine governing practice, supplemented by a pneumatic

temperature control, preset startup fuel limiting

and manual sequencing. Independent devices

provided protection against overspeed, overtemperature, fire, loss of flame, loss of lube oil and

high vibration.

Through the early years of the industry, gas

turbine control designs benefited from the

rapid growth in the field of control technology.

The hydro-mechanical design culminated in the

“fuel regulator” and automatic relay sequencing

for automatic startup, shutdown and cooldown

where appropriate for unattended installations.

The automatic relay sequencing, in combination

with rudimentary annunciator monitoring, also

allowed interfacing with SCADA (Supervisory

Control and Data Acquisition) systems for true

continuous remote control operation.

This was the basis for introduction of the first

electronic gas turbine control in 1968. This system, ultimately known as the SPEEDTRONIC™

Mark I Control, replaced the fuel regulator,

pneumatic temperature control and electromechanical starting fuel control with an electronic equivalent. The automatic relay sequencing was retained and the independent protective

functions were upgraded with electronic equivalents where appropriate. Because of its electrically dependent nature, emphasis was placed on

integrity of the power supply system, leading to a

DC-based system with AC- and shaft-powered

back-ups. These early electronic systems provided an order of magnitude increase in running

reliability and maintainability.

Once the changeover to electronics was

achieved, the rapid advances in electronic system technology resulted in similar advances in

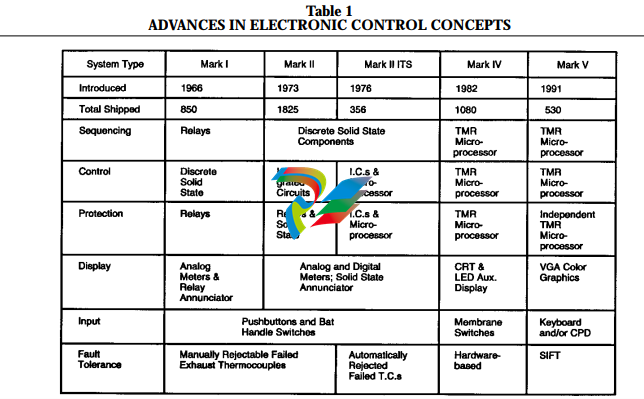

gas turbine control technology (Table 1). Note

that more than 40 years of gas turbine control

experience has involved more than 5,400 units,

while the 26 years of electronic control experience has been centered on more than 4,400 turbine installations. Throughout this time period,

the control philosophy shown in Table 2 has

developed and matured to match the capabilities of the existing technology. This philosophy

emphasizes safety of operation, reliability, flexibility, maintainability and ease of use, in that

order.

CONTROL SYSTEM

FUNCTIONS

The SPEEDTRONIC™ Gas Turbine Control

System performs many functions including fuel,

air and emissions control; sequencing of turbine

fuel and auxiliaries for startup, shutdown and

cooldown; synchronization and voltage matching of the generator and system; monitoring of

all turbine, control and auxiliary functions; and

protection against unsafe and adverse operating

conditions. All of these functions are performed

in an integrated manner that is tailored to

achieve the previously described philosophy in

the stated priority.

The speed and load control function acts to

control the fuel flow under part-load conditions

to satisfy the needs of the governor.

Temperature control limits fuel flow to a maximum consistent with achieving rated firing temperatures and controls air flow via the inlet

guide vanes to optimize part-load heat rates on

heat recovery applications. The operating limits

of the fuel control are shown in Figure 1. A

block diagram of the fuel, air and emissions control systems is shown in Figure 2. The input to

the system is the operator command for speed

(when separated from the grid) or load (when

connected). The outputs are the commands to

the gas and liquid fuel control systems, the inlet

guide vane positioning system and the emissions

control system. A more detailed discussion of

the control functionality required by the gas turbine may be found in Reference 1.

The fuel command signal is passed to the gas

and liquid fuel systems via the fuel signal divider

in accordance with the operator’s fuel selection.

Startup can be on either fuel and transfers

3

GER-3658D

Table 2

GAS TURBINE CONTROL PHILOSOPHY

• Single control failure alarms when running or during

startup

• Protection backs up control, thus independent

• Two independent means of shutdown will be available

• Double failure may cause shutdown, but will always

result in safe shutdown

• Generator-drive turbines will tolerate full-load rejection