Honeywell C200 TK-PRS021

Disclaimer

This document contains Honeywell proprietary information. Information contained herein is to be

used solely for the purpose submitted, and no part of this document or its contents shall be

reproduced, published, or disclosed to a third party without the express permission of Honeywell

International Sàrl.

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a purpose and makes no express

warranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages. The

information and specifications in this document are subject to change without notice.

Copyright 2019 - Honeywell International Sàrl

ABOUT THIS DOCUMENT

This guide provides information that will assist you in planning and designing activities, as well as

the installation, operation, and troubleshooting of C300 Process Controllers in a PlantCruise

system.

Starting with R501, C300 controllers (Hardware model — CC-PCNT02) provide an expanded

functionality of large memory capacity, primarily to support the Profit Controller. CC-PCNT02, with

the in-built firmware, is interoperable with CC-PCNT01 and enables easy synchronization,

Revision History

Revision Date Description

A August 2019 Initial release of the document.

C300 CONTROLLER PURPOSE

This section provides a quick comparison of C200 and C300 Controller features and reference to

topics in this book for a given task related to using the C300 Controller with the Experion system.

ATTENTION

The C300 Controller can be used with the Universal Input/Output (UIO) module for

replacing the TPS components such as Basic Controller (CB) and Extended Controller (EC).

For more information about the usage of the C300 Controller with the Universal

Input/Output (UIO) module, see Series 8 I/O User's Guide.

C300 Controller and C200 Controller comparison

The C300 Controller provides design improvements and greater operational capabilities for

process control over the chassis-based C200 controller. The following table is a listing that

compares design features and operational improvements of the C300 Controller with the C200

controller.

ATTENTION

The C300 - 20mS CEE Controller has all the features as the C300 - 50ms Controller with

exceptions related to the faster execution speed (20ms). The C300 - 20mS CEE controller

supports only the Series 8 I/O modules. Two new Series C I/O Modules (Speed Protection

Module (SPM) and Servo Valve Positioner Module (SVPM)) are only supported by the C300

- 20mS CEE Controller.

The C300 - 20mS CEE controller is only intended for Honeywell Turbine Control Solutions.

Controller

Feature

Comparison

Form Factor C200 - Chassis-based controller with plug-in modules for

Control Processor, I/O Link Interface, Redundancy, FTE

interface, Fieldbus, other I/O and control modules.

C300 - A single control module that plugs into an Input

Output Terminal Assembly (IOTA). Control module functions

include a Control processor, two I/O Link interfaces,

Controller

Feature

Comparison

Redundancy functions, and FTE interfaces.

Memory (RAM) C200 - 4MB User Memory

C300 - 16MB User Memory

Redundancy C200 -Two identically-equipped controller chassis that

contain two Redundancy Modules (RM) provide controller

redundancy.

C300 - Controller redundancy function is built in. A second

C300 Controller and redundancy cable is all that is required

for redundant controller operation. (No RMs)

I/O Link

Interface

C200 - An I/O Link Interface plug-in Module (IOLINK)

installed in the controller chassis is required to connect

PMIO I/O to the controller CPM.

C300 - Two I/O Link interfaces are built in to the controller.

Each I/O Link can connect with either PMIO I/O or Series 8

I/O modules.

Note: C300 - 20mS CEE Controller supports only Series 8

I/O modules.

Communications

Interface to

supervisory

network

C200 - Ethernet or Fault Tolerant Ethernet plug-in modules

are needed to connect to respective Ethernet and FTE

communication networks. ControlNet Interface plug-in

module is needed to connect with other ControlNet nodes.

C300 - Ethernet interface is built into the controller and

supports both Ethernet and redundant FTE

communications. No ControlNet interface.

Peer-to-Peer

Connections

C200 - Ethernet or Fault Tolerant Ethernet Bridge plug-in

modules are needed to connect to respective Ethernet and

FTE networks. ControlNet Interface plug-in module is

needed to connect with other ControlNet nodes.

C300 - Ethernet interface is built into the controller to

support both Ethernet and redundant FTE communications.

C300 connection to C200 controller is made through an

FTE Bridge module installed in the C200 chassis. No

ControlNet interface.

Note: C300 - 20mS CEE Controller does not support peerto-peer connection with C200E.

Function Blocks C200 and C300 - Both Controllers use the same standard

Experion function block types for control strategy execution.

There are some exceptions

Getting started

The following table lists some of the tasks covered in this document that are related to

implementing a C300 Controller in your Experion R300 system or later. If you are viewing this

document online, just click the reference to jump to the topic in this document.

l What task do you want to perform?

2.2.1 What task do you want to perform?

If you want to … Then, see this topic …

Plan and design a C300 Controller

installation

C300 Controller planning and

design

Know more about C300 hardware Series 8 control hardware

Identify C300 Controller

components

Know more about C300 Controller

performance

C300 Controller performance data

Install and wire C300 Controller hardware C300 Controller installation

Upgrade Controller firmware Upgrading C300 Controller

firmware

Create C300 Controller and CEE function

blocks

C300 Controller configuration

Configure CEE function blocks Configure CEEC300 block

Configure IOLINK function blocks Configure IOLINK function blocks

Configure a Secondary C300 Controller Configure a Secondary C300

Controller block

Convert a Non-redundant C300 Controller

to a redundant controller

Convert a non-redundant C300

Controller to a redundant controlle

If you want to … Then, see this topic …

Convert a redundant C300 Controller to a

Non-redundant controller

Convert a redundant C300

Controller to a non-redundant

controller

Reset Controller Device Index Reset Device Index and IP address

of a controller

View configuration parameter

descriptions

C300 configuration form reference

Load function blocks to C300

components

Load C300 Controller

Configuration

Reload components from Project Reloading components from

project

Review C300 Controller start up routines C300 Controller start up

Review C300 Controller operating

indications

C300 faceplate indicators/displays

Shutdown a C300 Controller Initiating C300 Controller

shutdown

Activate the Controller's CEE Activate C300 Controller's CEE

View Controller operations Viewing controller operation and

status in Control Builder

Using Station displays

Review C300 controller operating

behaviors Time management, Watchdog

Timer

C300 operating behaviors

Controller processing overload behavior

and recovery

C300 Controller processing

overload behavior

Review C300 Controller redundancy

functionality

C300 redundancy operation

Review C300 Controller maintenance and

replacement procedures

C300 Controller maintenance

Investigate a cause of a problem C300 Controller troubleshooting

Install and wire C300 Controller hardware C300 Controller installation

Review C300 Controller redundancy

functionality

C300 redundancy operation

C300 CONTROLLER PLANNING AND DESIGN

This section includes information about system planning and design of the C300 Controller. The

following topics are presented here.

l Review Experion system capabilities

l Control Hardware Planning Guide

l Series 8 control hardware

l Identify C300 Controller components

l C300 Controller performance data

3.1 Review PlantCruise. system capabilities

Read the Overview document so that you understand the basic concepts and terminology, and

appreciate the capabilities of PlantCruise.

Complement the information in this document with the data in the Server and Client Planning

Guide to cover all aspects of PlantCruise installation.

For planning and design topics for Engineering Station and clients as well as information about

adding third-party controllers, see the Server and Client Planning Guide.

l Planning for system security

3.1.1 Planning for system security

System security must be achieved at all levels in the Experion system to manage security threats.

For details on security related planning, refer to the Network and Security Planning Guide.

For controller hardware specific security planning, refer to the chapter Securing controller

hardware of the Network and Security Planning Guide.

3.2 Control Hardware Planning Guide

Refer to the Control Hardware Planning Guide for a general discussion of planning activities for

Experion Control hardware that covers:

l Initial planning and design

l Control network considerations

l Control hardware configuration

l Site selection and planning

l Control processing considerations

l Application licensing considerations

Series 8 control hardware

Series 8 control hardware consists of the following system components:

l C300 Controller is a distributed process controller and I/O gateway for the Experion system.

l Series 8 Input/Output Modules that feature HART-capable AI and AO modules, and a low level

Mux AI module. Digital input modules that support high voltage AC and 24V DC inputs.

l Series 8 form factor

l C300 Controller

l C300 controller model CC-PCNT02 – Enhanced Functionality

l C300 Controller execution environments

3.3.1 Series 8 form factor

All Series 8 control hardware is constructed using the same form factor; that is, the C300

Controller modules, Series 8 I/O modules, and Series 8 FIMs all mount on their associated Input

Output Termination Assemblies (IOTAs), which are installed on channel hardware specifically

designed to support Series 8 hardware installation. The module's circuit board assemblies are

housed in a plastic case with a round faceplate that identifies the module type and model number

along with status LEDs and a four-character alphanumeric display. The IOTA contains connectors

that accept the associated control module and the various I/O connectors for cables that connect

to other Series 8 control hardware. Below figure shows an example of the design.

For more details about Series 8 I/O, Level1 Switch and FIM modules refer to the following

documents:

l Series 8 I/O User's Guide

l Series C Mark II I/O User’s Guide

l Series 8 Fieldbus Interface Module User's Guide.

3.3.2 C300 Controller

The C300 Controller is constructed using the Series 8 form factor that employs an Input Output

Termination Assembly (IOTA) and an electronics module which mounts and connects to the IOTA.

This smaller controller footprint and ease of installation provides greater value for PlantCruise

users.

The C300 Controller fully supports configuration, load and execution of the standard function

blocks. Note that there are a few exceptions defined below.

Exceptions

The following function blocks are not supported by the C300 Controller:

l The LIOM function block set.

l CAB related function blocks other than the Custom Data Block (CDB)

3.3.3 C300 - 20mS CEE Controller

The C300 - 20mS CEE Controller uses the same Controller Module and IOTA as the C300 - 50ms

controller. It uses a different firmware image that supports faster control execution. The C300 - 20

mS CEE supports Speed Protection Module (SPM) that monitors turbine speed inputs, analog

inputs, and digital status inputs, and controls digital outputs and a single analog output. Servo

Valve Positioner (SVP) Module monitors valve position either with LVDT/RVDT interface or analog

input and two digital inputs, and controls the valve movement either with servo coil current or

analog output.

The C300 - 20mS CEE Controller fully supports configuration, load and execution of the standard

function blocks supported in the C300 - 50ms Controller. Note that there are a few exceptions

defined below.

Exceptions

The C300 - 20 controller does not support the following function blocks.

l LIOM function block set

l Custom Data Block (CDB)

l Profibus Gateway Module (PGM2) function blocks

l SIM C300 20ms function block

l FIM4 function block

l Wireless Device Manager (WDM) function blocks

l Sequential Control Module (SCM) function block

l Recipe Control Module (RCM) function block

l Unit Control Module (UCM) function block

l Phase Block

l Series A - Serial Interface Module (SIM) (for third party integration)

l Series H module

l Profibus I/O Module

l PMIO function blocks

l Exchange blocks

l Change Execute (CHGEXEC) Block

l Fieldbus blocks

l DeviceNet blocks

l Profibus blocks

l American Gas Association (AGA) blocks

l A-B Drive Interface Library

o Legacy SCANport Drives

o PowerFlex Drives

l JAGXTREME block library

o JAGXCHAN

o JAGXTERM

l QIMPACT Library block

o QIPACCHAN

o QIPACTERM

ATTENTION

C300-20ms controller does not support peer-to-peer communication with the following:

l FIM4

l Profibus Gateway Module (PGM2)

l C200E

l Wireless Device Manager (WDM)

C300 Controller redundancy

The C300 Controller may operate in both non-redundant and redundant configurations.

Redundant operation requires a second identical controller and connecting cables, which is the

typical configuration. The switchover time from the active primary controller to the backup

controller of a redundant pair is less than 500 milliseconds.

ATTENTION

The switchover time from the active primary C300-20ms controller to the backup C300-

20ms controller of a redundant C300-20ms controller pair is less than 200 milliseconds.

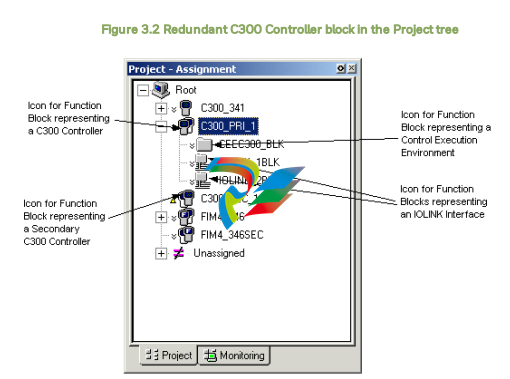

C300 Controller block

When a C300 Controller block is added to the Project tree in Control Builder, a graphic

representation of a controller module and its resident function blocks appears as shown in Figure

2. The function blocks that are contained in the controller support multiple execution

environments. A Control Execution Environment block (CEEC300) and two IOLINK blocks are

contained in the controller and appear under the controller. When the controller block is

configured as redundant, the secondary controller block is added in the Project tree.

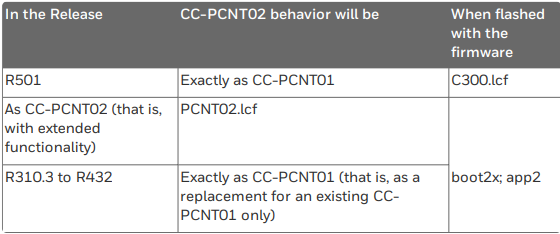

C300 controller model CC-PCNT02 – Enhanced Functionality

Beginning with R501, a new C300 controller model with enhanced functionality: the CC-PCNT02,

has been introduced to meet the demand for expanded memory and to address the ASIC

hardware (Spartan-IIE FPGA) obsolescence.

While the initial release of C300 (CC-PCNT01) contained a Processor board with 32 MB of main

Memory and Application board that used the Spartan-IIE FPGA family, the new release of C300

(CC-PCNT02) gets 64 MB of main Memory and an Application board that uses the Spartan-3A

FPGA family ASIC.

The enhanced memory enables the CC-PCNT02 to provide extended functionalities such as

support for Profit Controller and Ethernet Interface Module (IEC & EIP) blocks. Besides this, there

is no significant change in the functionality offered by the CC-PCNT02 model compared to CCPCNT01.

The CC-PCNT02 may be used as a compatible field replacement for CC-PCNT01 by installing the

current-release firmware image with Ctools. The following table summarizes the supported

releases and the firmware required to enable CC-PCNT02 to either work with enhanced

functionality or only replace CC-PCNT01.