EMERSONMVME6100 Single Board Computer Installation and Use

Overview of Contents

This manual is divided into the following chapters and appendices:

Chapter 1, Hardware Preparation and Installation, provides MVME6100 board preparation and

installation instructions, as well as ESD precautionary notes.

Chapter 2, Startup and Operation, provides the power-up procedure and identifies the switches

and indicators on the MVMEM6100.

Chapter 3, MOTLoad Firmware, describes the basic features of the MOTLoad firmware product.

Chapter 4, Functional Description, describes the MVME6100 on a block diagram level.

Chapter 5, Pin Assignments, provides pin assignments for various headers and connectors on

the MMVE6100 single-board computer.

Appendix A, Specifications, provides power requirements and environmental specifications.

Appendix B, Thermal Validation, provides information to conduct thermal evaluations and

identifies thermally significant components along with their maximum allowable operating

temperatures.

Appendix C, Related Documentation, provides a listing of related Emerson manuals, vendor

documentation, and industry specifications.

The MVME61006E Series Single-Board Computer Installation and Use manual provides the

information you will need to install and configure your MVME61006E single-board computer

(hereinafter referred to as MVME6100). It provides specific preparation and installation

information, and data applicable to the board.

As of the printing date of this manual, the MVME61006E supports the models listed below.

Abbreviations

Conventions

The following table describes the conventions used throughout this manual.

Model Number Description

MVME61006E-0161 1.267 GHz MPC7457 processor, 512MB DDR memory, 128MB Flash,

Scanbe handles

MVME61006E-0163 1.267 GHz MPC7457 processor, 512MB DDR memory,128MB Flash, IEEE

handles

MVME61006E-0171 1.267 GHz MPC7457 processor, 1GB DDR memory, 128MB Flash, Scanbe

handles

MVME61006E-0173 1.267 GHz MPC7457 processor, 1GB DDR memory, 128MB Flash, IEEE

handles

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0 through F), for example used for addresses and

offsets

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

or commands in body text

Courier + Bold Used to characterize user input and to separate it

from system output

Reference Used for references and for table and figure

descriptions

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

Summary of Changes

This is the third edition of the Installation and Use manual. It supersedes the November 2007

edition and incorporates the following changes.

Comments and Suggestions

We welcome and appreciate your comments on our documentation. We want to know what

you think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online Form

In "Area of Interest" select "Technical Documentation". Be sure to include the title, part number,

and revision of the manual and tell us how you used it.

Part Number Date Changes

6806800D58E March 2009 Added csUserAltBoot command to Table "MOTLoad

Commands" on page 33 , editorial changes

6806800D58D April 2008 Updated to Emerson publications style.

6806800D58C January 2008 Updated to remove two incorrect sources of reset. See Reset

Control Logic on page 71. Table 5-13 on page 90 was updated

to indicate both possible uses of pins C1, C2, C3, C4, Z25, Z27,

Z29, and Z31 (when J30 is configured for rear Ethernet and

when J30 is configued for full PMC mode).

6806800D58B November

2007

Updated to better describe how to configure the VIO keying

pins for the PMC sites. See PMC I/O Voltage Configuration on

page 22. Also, Table 5-12 on page 89 was updated to identify

the Geographical Addressing pins on Row D of the P1

connector and minor updates were made to correct the hot

link to the literature catalog web site and update the reader

comments link.

Overview

This chapter contains the following information:

z Board preparation and installation instructions

z ESD precautionary notes

1.2 Description

The MVME6100 is a single-slot, single-board computer based on the MPC7457 processor, the

MV64360 system controller, the Tsi148 VME Bridge ASIC, up to 1 GB of ECC-protected DDR

DRAM, up to 128MB of flash memory, and a dual Gigabit Ethernet interface.

Front panel connectors on the MVME6100 board include: two RJ-45 connectors for the Gigabit

Ethernet, one RJ-45 connector for the asynchronous serial port with integrated LEDs for

BRDFAIL and CPU run indication, and a combined reset and abort switch.

The MVME6100 is shipped with one additional asynchronous serial port routed to an on-board

header.

The MVME6100 contains two IEEE1386.1 PCI, PCI-X capable mezzanine card slots. The PMC

slots are 64-bit capable and support both front and rear I/O. All I/O pins of PMC slot 1 and 46

I/O pins of PMC slot 2 are routed to the 5-row DIN, P2 connector. I/O pins 1 through 64 from

J14 of PMC slot 1 are routed to row C and row A of P2. I/O pins 1 through 46 from J24 of PMC

slot 2 are routed to row D and row Z of P2.

The MVME6100 has two planar PCI buses (PCI0 and PCI1). In order to support a more generic

PCI bus hierarchy nomenclature, the MV64360 PCI buses will be referred to in this document

as PCI bus 0 (root bridge instance 0, bus 0) and PCI bus 1 (root bridge instance 1, bus 0). PCI bus

1 connects to PMC slots 1 and 2 of the board. PCI bus 0 connects to the Tsi148 VME Bridge ASIC

and PMCspan bridge (PCI6520). This interface operates at PCI-X (133 MHz) speed. Both PCI

planar buses are controlled by the MV64360 system controller.

Voltage Input/Output (VIO) for PCI bus 1 is set by the location of the PMC keying pins; both pins

should be set to designate the same VIO, either +3.3V or +5V.

The MVME6100 board interfaces to the VMEbus via the P1 and P2 connectors, which use 5-row

160-pin connectors as specified in the VME64 Extension Standard. It also draws +12V and +5V

power from the VMEbus backplane through these two connectors. The +3.3V, +2.5V, +1.8V,

and processor core supplies are regulated on-board from the +5V power.

For maximum VMEbus performance, the MVME6100 should be mounted in a VME64x

compatible backplane (5-row). 2eSST transfers are not supported when a 3-row backplane is

used.

The MVME6100 supports multiple modes of I/O operation. By default, the board is configured

for Ethernet port 2 to the front panel (non-specific transition module), and PMC slot 1 in IPMC

mode. The board can be configured to route Ethernet port 2 to P2 and support MVME712M or

MVME761 transition modules. The front/rear Ethernet and transition module options are

configured by jumper block J30.

Selection of PMC slot 1 in PMC or IPMC mode is done by the jumper blocks J10, J15-J18, and

J25-J28 (see Table 1-2 on page 19). IPMC mode is selected when an IPMC712 or IPMC761

module is used. If an IPMC is used, J30 should be configured for the appropriate transition

module (see J30 configuration options as illustrated in Front/Rear Ethernet and Transition Module

Options Header (J30) on page 23).

The IPMC712 and IPMC761 use AD11 as the IDSEL line for the Winbond PCI-ISA bridge device.

This device supplies the four serial and one parallel port of the IPMC7xx module. The Discovery

II PHB (MV64360) does not recognize address lines below AD16. For this reason, although an

IPMC7xx module may be used on an MVME6100, the serial and parallel ports are not available,

nor addressable. This issue will be resolved at a later date.

Other functions, such as Ethernet and SCSI interfaces, are function independent of the

Winbond IDSEL line. The wide SCSI interface can only be supported through IPMC connector

J3.

PMC mode is backwards compatible with the MVME5100 and MVME5500 and is accomplished

by configuring the on-board jumpers.

1.3 Getting Started

This section provides an overview of the steps necessary to install and power up the

MVME6100 and a brief section on unpacking and ESD precautions.

Overview of Startup Procedures

The following table lists the things you will need to do before you can use this board and tells

where to find the information you need to perform each step. Be sure to read this entire

chapter, including all Caution and Warning notes, before you begin.

1.3.2 Unpacking Guidelines

Unpack the equipment from the shipping carton. Refer to the packing list and verify that all

items are present. Save the packing material for storing and reshipping of equipment.

Table 1-1 Startup Overview

What you need to do... Refer to...

Unpack the hardware. Unpacking Guidelines on page 17

Configure the hardware by setting jumpers on the board. Configuring the Hardware on page 18

Install the MVME6100 board in a chassis. Installing the Blade on page 27

Connect any other equipment you will be using Connecting to Peripherals on page 27

Verify the hardware is installed. Completing the Installation on page 28

If the shipping carton is damaged upon receipt, request that the carrier’s agent be present

during the unpacking and inspection of the equipment.

1.4 Configuring the Hardware

This section discusses certain hardware and software tasks that may need to be performed

prior to installing the board in a chassis.

To produce the desired configuration and ensure proper operation of the MVME6100, you may

need to carry out certain hardware modifications before installing the module.

Most options on the MVME6100 are software configurable. Configuration changes are made

by setting bits in control registers after the board is installed in a system.

Avoid touching areas of integrated circuitry; static discharge can damage circuits.

Emerson strongly recommends that you use an antistatic wrist strap and a conductive foam

pad when installing or upgrading a system. Electronic components, such as disk drives,

computer boards, and memory modules can be extremely sensitive to electrostatic

discharge (ESD). After removing the component from its protective wrapper or from the

system, place the component flat on a grounded, static-free surface (and, in the case of a

board, component side up). Do not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing an

antistatic wrist strap (available at electronics stores) that is attached to an active electrical

ground. Note that a system chassis may not be grounded if it is unplugged.

Inserting or removing modules with power applied may result in damage to module

components.

Dangerous voltages, capable of causing death, are present in this equipment. Use extreme

caution when handling, testing, and adjusting

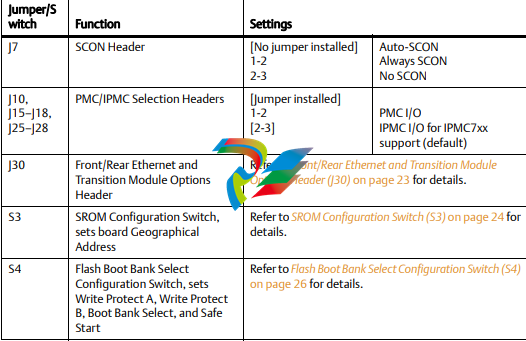

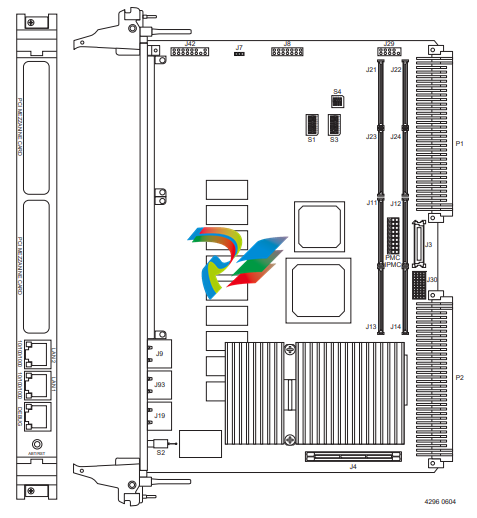

Jumpers/switches are used to control those options that are not software configurable. These jumper settings are described further on in this section. If you are resetting the board jumpers from their default settings, it is important to verify that all settings are reset properly. Figure 1-1 illustrates the placement of the jumpers, headers, connectors, switches, and various other components on the MVME6100. There are several manually configurable headers on the MVME6100 and their settings are shown in Table 1-2. Each header’s default setting is enclosed in brackets. For pin assignments on the MVME6100, refer to Chapter 5, Pin Assignments. Items in brackets are factory default settings.

The MVME6100 is factory tested and shipped with the configuration described in the following

sections

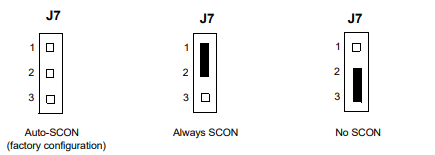

SCON Header (J7)

A 3-pin planar header allows the choice for auto/enable/disable SCON VME configuration. A

jumper installed across pins 1 and 2 configures for SCON always enabled. A jumper installed

across pins 2 and 3 configures for SCON disabled. No jumper installed configures for auto

SCON

PMC/IPMC Selection Headers (J10, J15 — J18, J25 — J28)

Nine 3-pin planar headers are for PMC/IPMC mode I/O selection for PMC slot 1. These nine

headers can also be combined into one single header block where a block shunt can be used as

a jumper.

.png)