KongsbergK-Gauge TOP KONGSBERG Tank Overfill Protection System

K-Gauge TOP

KONGSBERG Tank Overfill Protection System

Features

• No moving parts

• Continuous verification - AutroCAL®

• Configurable alarm limits

• Closed level gauge suitable for all tank

designs

• Utilize 50 mm still pipe

• Modular design

• Intrinsically safe for use in all zones

General description

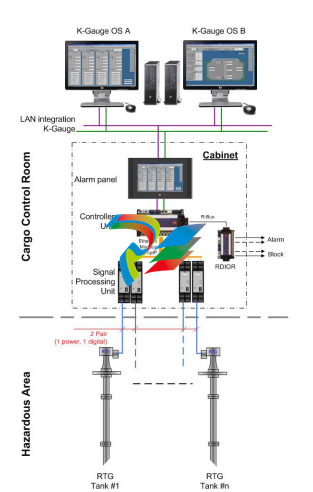

The KONGSBERG radar based Tank Overfill

Protection System for gas carriers meets the IMO

requirements ‘Cargo Tank Overfill Protections

System’.

The system includes radar tank gauges,

processing and alarm handling units, and a

dedicated operator panel. Integration to K-Gauge

level gauging system is included with mimic

presentation on the Operator Stations.

All equipment on deck is designed for rugged

marine environment and manufactured in AISI

316L stainless steel. Accurate measurement is

possible regardless of the tank atmospheric

conditions. Flexible hardware and software

modules ensure easy adaptation to Liquefied

Petroleum Gases (Propane, Butane), Ethylene,

Ammonia (NH3), and Liquefied Natural Gas.

Principle of operation

The RTG emits a frequency sweeping

microwave signal through a still pipe. The

distance is derived from the time delay of the

reflected signal.

The still pipe is assembled by one top-, middleand bottom section. Total length of the still pipe

is typically 10 meter, and the system allows for

several adjustable alarm limits in the area of the

middle section (6 meter).

The pipes have ventilation holes allowing the

vapour pressure inside and outside the pipe to

stabilize, thus allowing the liquid to rise or fall

unimpeded in the pipe.

Each pipe section is supplied with flanges

prepared with reference markers. The liquid level

and the markers are measured simultaneously, so

the system automatically verifies itself at every

measurement. By careful calibration of the pipe

sections length before installation, the positions

of the markers are recorded and stored in the

system. By comparing the liquid echo with the

reference marker echo, a continuous autocalibration of the level gauge is done.

The electronic unit in the RTG includes a

patented signal detection method that ensures

optimum performance. Combined with its superb

signal-to-noise ration, GLA-310/5TOP offers the

highest measurement reliability and accuracy.

Each RTG is connected to a dedicated signal

processing unit, where the AutroCAL® principle

is employed.

AutroCAL®

AutroCAL® is a unique calibration and

verification function in the KONGSBERG

system. Gas vapor density and mixture of gases

influence the propagation speed of the radar

signal, thus the accuracy of the measurement.

By using pipe joint reference markers,

AutroCAL® continuously compensates for the

changes caused by the differences in the

propagation speed.

With AutroCAL®, the influence of the gas vapor

density and composition is measured and

compensated for automatically.

Building blocks

The K-Gauge TOP system consists of the

following hardware units:

• Radar Tank Gauge: GLA-310/5TOP (1 ea tank)

• Radar Processing Unit: GLK-300/x (1 ea tank)

• Remote Controller Unit: RCU502

• Relay output unit: RDIOR420

• Operator/Alarm Panel

• Interface to K-Gauge Operator Station

Radar Tank Gauge GLA-310/5

Measuring range: 0 to 10 meter (increased measuring ranges on request)

RTG RMS accuracy: 2 mm

System RMS accuracy: 5 mm

Ex classification:

Ex certification:

Ex ia IIC T4

09ATEX1330X

Frequency: X-band (10 GHz)

Materials: AISI 316(L) in housing and connection box

PTFE/PEEK antenna lense facing the cargo

AISI 316(L) or Al alloy 5083 in still pipe

Protection:

Weight:

Cable size:

IP 66/67

10.7 kg

Ø12-Ø20 mm

Environmental temperature: -45 °C to +85 °C

Tank temperature:

Tank pressure

Down to -165 °C

Up to 10 bar g

TOP processing system

Power supply voltage: 24 VDC ±20 %

Operating temperature: 0 °C to +70 °C

Operating humidity: 95 %, non-condensing

Quality standard: ISO 9001

Generic EMC standard: Emission: IEC 60945 / Immunity: IEC 61000-4