LAUERfor the operating consoles PCS 009, PCS 090, PCS 095, PCS 095.1

for the operating consoles

PCS 009, PCS 090, PCS 095, PCS 095.1

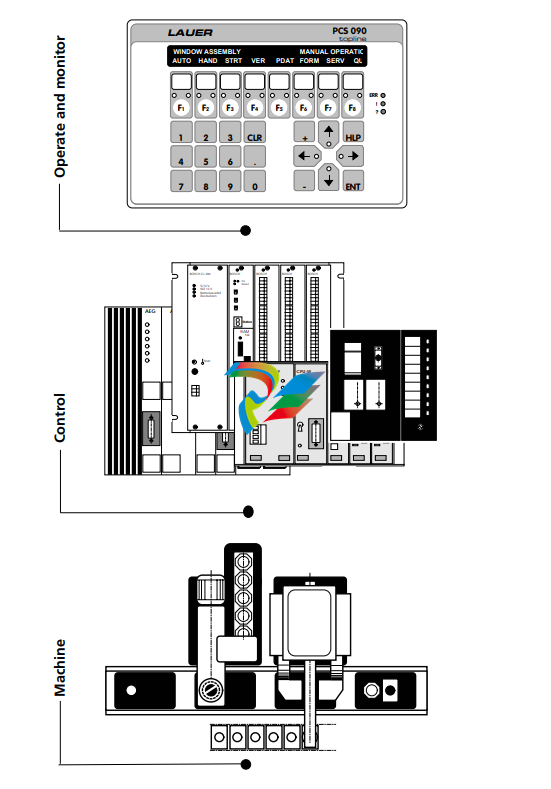

The operating consoles PCStopline offer the

highest degree on perfection, unparalled in

design and function. PCStopline keeps everything under control - from the PCSmini to the

PCSmaxi, with a superior operating culture and

an unlimited setup freedom.

PCS, the first programmable operating console

with a large selection of "ready-to-use" operating functions or operating tools which are

simply selected via instructions. You can realize

even the most unuasal operating requests at

ease and in a minimum of time.

Today this way and tomorrow that way

One standard hardware for virtually thousands

of different operating situations. Without extensive wiring and dozens of I/O points.

PCS for operating. What else?

■ Machine operation using 8 (PCS 009, PCS 090) or 16 (PCS 095, PCS 095.1)

freely assignable keys. These F01 to F08/F16 labeled keys can be application

specifically inscribed and are provided to the controller as status bits.

■ Machine operation using 4 (PCS 009), 16 (PCS 090) or 32 (PCS 095, PCS

095.1) freely usable LEDs. These can be assigned the indicating states ON,

DARK, FLASHING, and INVERSE FLASHING. A green and a yellow LED is allocated

to each function key.

■ Display of fixed texts with integrated variable values. The values can be

represented selectably as numerical values or in text format.

■ Representation of the contents of 233 words as variables. In addition, 650

external variables can be defined. 9 variable formats (from bit to timer) are

available.

■ 3 text groups, 128 operating texts as menu and idle texts, 128 message texts

with up to 332 lines, 5 help texts with up to 32 lines.

■ 127 menus with 255 menu nodes each for any menu configurations.

■ 4 different deletion modes. For every message, 1 of 4 possible deletion modes

can be selected.

■ Modification of the content of any word within the transfer area. Using the

integrated editor all possible representation formats can be setup.

■ 7 priority levels for idle text up to help text, 3 message priorities Information,

Warning, Fault. This working-condition related management significantly offloads the programmable controller program.

■ Monitoring of rising or falling edges of 128 consecutive bits. The assignment

of texts, the manage-ment of 3 priority levels (Information, Warnings, and Faults),

keeping the timely sequence as much as possible, organization of the FIRST

MESSAGE, LAST MESSAGE, and CYCLIC DISPLAY, the individually settable deletion behaviour, and the representation formats NORMAL and FLASHING are tasks

which are managed by the PCS by itself.

■ Communication monitoring (wire-break, short circuit). A very efficient data

transfer is secured by the integrated priority management in connection with the

intelligent package length optimization, the high thruput rate and the fault tole

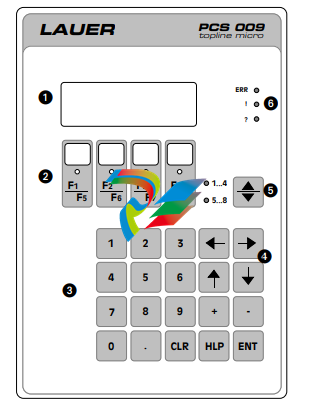

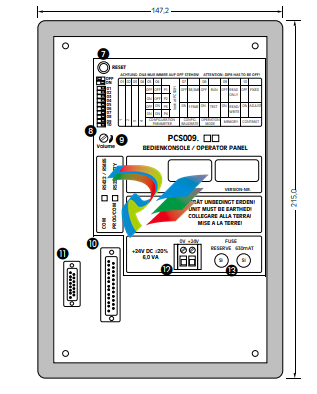

Operator Panel PCS 009

1 = LCD-Display, 4 lines each with 40 characters

2 = Function keys (also as soft keys) F1...F8 with a

greem message LED

3 = 10 key keyboard for nominal value input

4 = cursor and control keys for menus and nominal

value input

5 = Switch key (Shift key) for function keys (F1..F4,

F5..F9)

6 = Important information LEDs on the PCS status

7 = Reset key

8 = DIL switch for the PCS 009

9 = Volume for acoustic signal

J = Serial interface RS 232/TTY for communication

K = Serial interface RS 422/RS 485 for communication

L = Operating voltage terminals

M = Fuse with reserve fuse

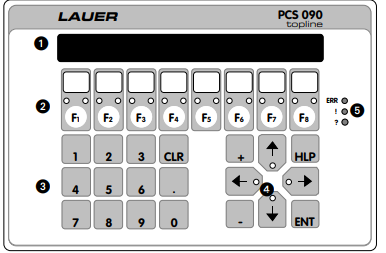

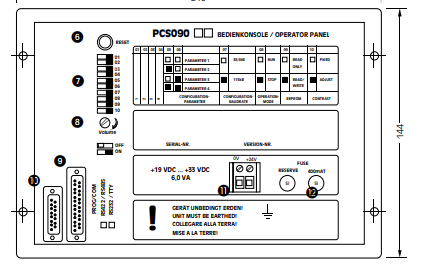

Operator Panel PCS 090

1 = LCD-display, 2 lines each with 40 characters

2 = Function keys (also as soft keys) F1...F8 with a

yellow and green message LED

3 = 10 key keyboard for nominal value input

4 = Cursor keys with LED and cursor control keys for

menus and nominal value input

5 = Important information LED's on the PCS status

6 = Reset key

7 = DIL-switch for the PCS 090

8 = Volume for acoustic signal

9 = Serial interface RS 232/TTY for the communication

J = Serial interface RS 422/RS 485 for the

communication

K = Operating voltage terminals

L = Fuse with reserve fuse

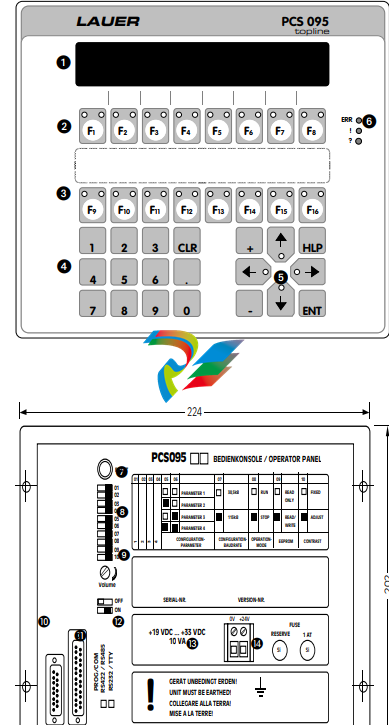

Operator Panel PCS 095/PCS 095.1

1 = LCD-display, 4 lines each with 40

characters

2 = Function keys (also soft keys) F1...F8

each with a yellow and a green

message LED

3 = Function keys F9...F16 each with a

yellow and a green mesage LED

4 = Ten key keyboard for nominal value

input

5 = Cursor key with LED and control key for

menu and nominal value input

6 = Important information LEDs on the PCS

status

7 = Reset key

8 = DIL switch for the PCS 095

9 = Volume for acoustic signals

J = Serial interface RS 232/TTY for the

communication

K = Serial interface RS 422/RS 485 for

the communication

L = Serial interface RS 232/TTY for the

programming and for the PCS 095.1

as Printer interface

M = Operating voltage terminals

N = Fuse with reserve fuse

Communication between any PLC and the PCS occurs as follows:

The PCS writes in predetermined word areas of the PLC, functions or nominal values,

which the PLC then reads and interprets.

The PLC writes in predetermined word areas functions or actual values, which are

automatically read and interpreted by the PCS. Independently of the PLC there are

maximum 256 words of 16 bit, that is to say 4096 inputs / outputs for the PCS/PLC

communication available.

... and rapid set-up of a particular operational requirement

1 First define the specification and decide on the required PCS (PCS micro, PCS

mini, PCS midi or PCS maxi)

2 Allocate the word and bit number to variables (actual- and nominal values).

3 Create the texts for operational guidance and help functions as well as for

displays of machine conditions.

4 Determine the message texts and apply these words to them, subdivide the

message texts into 3 priority groups

■ Information

■ Warnings

■ Faults

and take into consideration the differing cancel modes, display and message

modes. Display and message modes can be altered by the PLC at any time.

5 Define the menus and the menu operating texts.

6 Transfer the data file (variables, texts, menus) which was made in the PC or PG

under MSDOS/DRDOS or compatible DOS-system, with the software PCSPRO

into the PCS.

7 Implement and parameterize the PLC specific operating software (PCS 91.nn,

see overall view of information) in the users' programme.

8 Connect the PCS via the adapter cable with the PLC. Test together the operation

and control of the PCS and PLC and adjust if necessary

Machines produce different parts. Therefore quick and selective alterations of finished

sizes and functions (variables) are especially important for increased flexibility.

The PCS features a convenient method of processing the variables. 650 external variables (freely definable) and 6 internal variables are supervised from the PCS.

The value of the external variables are stoped in the words

30...255. The PCS differentiates

between actual values and nominal values:

ACTUAL: The value in the word

is the actual value. The PCS can

only display the value.

NOMINAL: The standing value

in the word is the nominal value.

The value can be displayed and

changed by the PCS.

NOMINAL VALUE-P: The private value in the word is a nominal value. The PCS can display

the value. It can be changed only

if this is allowed by the word 14

bit 7 = log 1 (key switch or DILswitch 1...4 on the rear side of

the PCS). When the bit 7 of word

14 = log 0, the display of the

actual value follows.

Internal Variables

NAME CONTENTS FORMAT LENGTH ACTUAL/NOMINAL

ZP NUMBER OF INFORMATIONS BIN 3 ACTUAL

ZQ NUMBER OF WARNINGS BIN 3 ACTUAL

ZR NUMBER OF FAULTS BIN 3 ACTUAL

ZT MENU NUMBER BIN 2 ACTUAL

ZV SCROLL TIME BIN 2 NOMINAL

ZX INTERFACE FAULTS BIN 2 ACTUAL

External Variables

FORMAT, LENGTH

BIT variable max. length 40 characters

STRING variable max. length 40 characters

CSTRING variable max. length 40 characters

WORD variable KM, KH, KY: length: 17, 4, 7 characters

ASCII variable max. length 16 characters

BCD-1 variable max. length 4 digits

BCD0-1 variable *) max. length 4 digits

BCD-2 variable max. length 8 digits

BCD0-2 variable *) max. length 8 digits

BIN-1, BIN-A variable max. length 16 bits/11 digits

BIN0-1, BIN0-A variable *) max. length 16 bits/11 digits

BIN-2, BIN-B variable max. length 32 bits/11 digits

BIN0-2, BIN0-B variable *) max. length 32 bits/11 digits

VBIN-1, VBIN-A variable max. length 16 bits/11 digits + operational sign

VBIN0-1, VBIN0-A variable *) max. length 16 bits/11 digits + operational sign

VBIN-2,V BIN-B variable max. length 32 bits/11 digits + operational sign

VBIN0-2, VBIN0-B variable *) max. length 32 bits/11 digits + operational sign

Timer variable max. length 40 characters

*) BIN0...- and VBIN0... variable are only programmable with PCSPRO

The BIT variable

When two possibilities can be selected at an input, the descision is taken by the bit

variable. This is in the form of an ON/OFF switch.

Every switch position represents an inscription (text) which appears in the display.

Each bit variable occupies a bit. A data word can also take on up to 16 differing bit

variables or switches.

Example: A wood shavings vacuum absorption cleaner shall be switched on or off

in bit 2 data word 33.

The +/- switch selects the inscription or the switching position. The bit bears the value

of the inscription. The first inscription carries the value log 0, the second bears the

value log 1.

STRING variable

When two or more possibilities can be selected at an input, the decision is made by

the STRING variable. It corresponds to a selector switch.

With STRING variables, every switch position is classified with an inscribed text, which

appears in the display. Every STRING value carries a data word with up to 256 switch

positions. The switch position is deposited in low bytes of the data word.

Example: The frame material shall be selected in data word 40.

The inscription or switching position is selected with the +/- key. Acceptance follows

with the ENTER key.

CSTRING variable

The CSTRING variable corresponds to STRING variable. Acceptance follows directly

after using the +/- key without ENTER.