lsVariable Frequency Drive / InverterStarvert iS5

Sensorless, sensored vector controlled iS5,

keeps your application in more stable,

durable and precise condition

Standard features

■kW / Voltage Ratings:

�0.75~55kW, 200-230VAC, 3 phase

�0.75~75kW, 380-480VAC, 3 phase

■Enclosure: IP00 ~ IP20

■Inverter Type: PWM with IGBT

■Control Method: Sensorless/Sensored Vector

■1~15kHz Carrier Frequency (1~8kHz. over 30kW)

■0~400Hz Output Frequency

■Removable Keypad (Able to read & write parameters)

■Intelligent Accel/Decel for Trip-Free Operation

■Auto Tuning

■8 Multi-Function Inputs

■1 Multi-Function Outputs

■Failure Relay

■Built-in PID Control

■Pre-Set Speeds

■Wire Operation

■Multi-step Programmable Run Patterns

■Auto Torque Boost

■DC Injection Braking

■Stall Prevention

■Built-In Braking Circuit for 0.75 ~ 7.5kW units

Options

■Communications Board:

�RS-485

�DeviceNet

�F-Net

�ModBus-RTU

�ProfiBus DP

�Extended I/O Module

-Sub-A Board:

3 Multi-Function Input

3 Multi-Function Output

-Sub-B Board :

Encoder Plus Input

Encoder Plus Output

-Sub-C Board :

3 Multi-Function Input

3 Multi-Function Output

Aux. Analog Reference Frequency (Isolated)

■Cable for Remote Keypad Operations

■Dynamic Braking Units for 11~75kW Inverters

■Dynamic Braking Resistors

Application

■Traverse

■Draw

■MMC (Mult Motor Control)

■Converting

■Material Handling

■Web Processing

■Fan/Pump Controls

■Conveyors

■Industrial Washing machine, etc.

Conformity to global standards

■UL and cUL listed for North America

■CE marked for Europe

■Quality process controlled by ISO9001, ISO14000

Starvert iS5

03

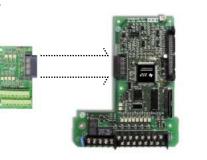

Extended I/O boards

The iS5 has several additional I/O boards that can be easily mounted into the connection terminal on control

board. Each I/O board is standardized for a specific I/O requirement.

The three main I/O boards are "Sub-board A", "Sub-board B" and "Sub-board C".

This helps system engineer to design most adequate and cost effective system

using the exactly necessary number of I/Os and functions.

It is extendable and changeable in case of system upgrade or change.

The control parameters and detailed functions for these boards

are not shown until any of them is inserted.

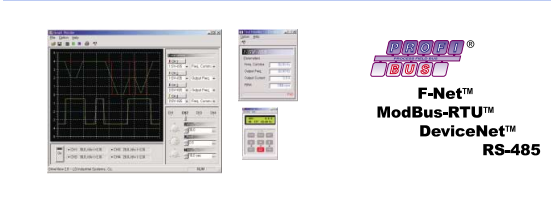

Diversity of communication interfaces

The iS5 provides most popular communication interfaces such as Device Net, Profibus DP, Modbus-RTU,

RS485 and F-Net (LG proprietary protocol for LG PLC communication).

The "DriveviewTM" software offers Window® based computer monitoring tool through RS-485 interface with

graphic capture, keypad emulator, parameter edit, and text monitor. It is applicable for all LG inverters

Built-in PID control

It is valuable in process control. The built-in PID algorithm controls flow, temperature, pressure, etc. through the

proportional, integral and differential calculus between the feedback value and reference value in closed loop.

The high speed CPU makes the calculation easy and fast.

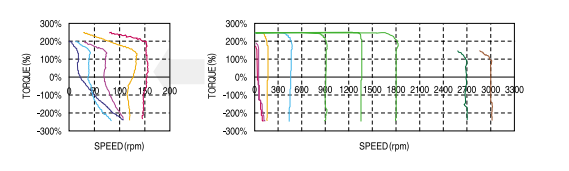

Sensorless vector control

The iS5 adopts sensorless vector control algorithm, and it improves not only the torque control characteristics, but the speed

controlability in an uncertain condition caused by the load variation as well.

The iS5 especially generates strong torque at a low speed range as shown below.

Auto tuning

The auto tuning algorithm in iS5 sets the motor factors automatically. It brings the traditional commissioning difficulties mainly in

low speed by the load variation and the low torque generation to a settlement.

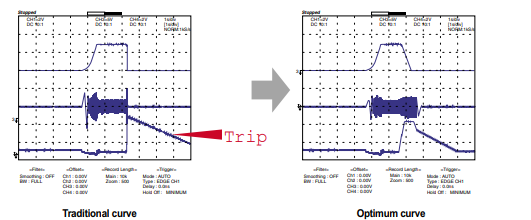

Optimum acceleration and deceleration

To make a maximum torque during the acceleration and deceleration, so called "trip free" function is acting during acceleration

and deceleration. Both of Acceleration and deceleration may cause a trip in case that it is manually programmed. The 32-bit

DSP CPU monitors the current transition during the acceleration and deceleration to program an optimum curve that is under

the triptrigering level automatically.

For your safety, please read user's manual thoroughly before operating.

• Contact the nearest authorized service facility for examination, repair, or adjustment.

• Please contact a qualified service technician when you need maintenance.

Do not disassemble or repair by yourself!

Safety Instructions • Any maintenance and inspection shall be performed by the personnel having expertise concerned.

.png)

.png)

.png)