GE Energy Mark* VIe Control Product Description

Introduction

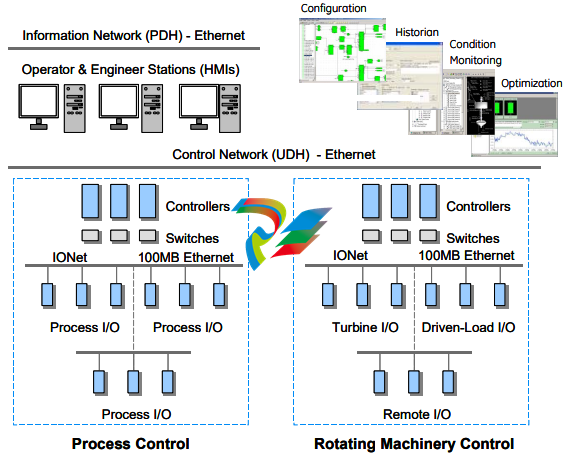

Mark* VIe is a flexible control system for multiple applications. It features highspeed, networked I/O for simplex, dual, and triple redundant systems. Industrystandard Ethernet communications are used for I/O, controllers, and supervisory

interface to operator and maintenance stations, and third-party systems.

ToolboxST* is used for Mark VIe and related controls as a common software

platform for programming, configuring I/O, trending, and analyzing diagnostics. It

provides a single source of quality, time-coherent data at the controller and plant

level for effectively managing equipment assets.

Architecture

A single-board controller is the heart of the system. It includes the main processor

and redundant Ethernet drivers for communicating with networked I/O and

additional Ethernet drivers for the control network. A QNX® real-time, multitasking

operating system is used for the main processor and I/O. Application software is

provided in a configurable control block language, and is stored in non-volatile

memory. It conforms to IEEE-854 32-bit floating-point format.

IONet is a dedicated, full-duplex, point-to-point protocol that provides a

deterministic, high-speed 100 MB communications network suitable for local or

remote I/O with a fiber interface. It provides communication between the main

processor(s) and networked I/O blocks, called I/O packs.

100 MB Ethernet is used for

communication to local and

remote I/O packs. The IONet

is available in single, dual,

and triple configurations.

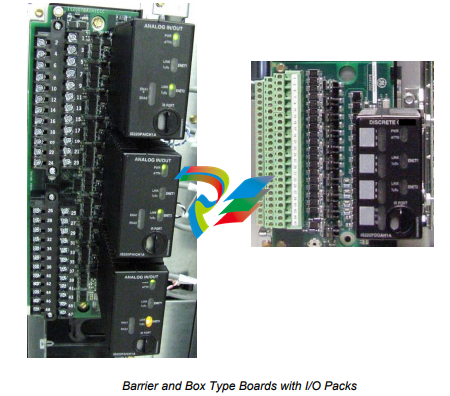

Each I/O pack is mounted on a board with barrier or box-type terminal blocks. The

I/O pack contains two Ethernet ports, a power supply, a local processor, and a data

acquisition board. Computation power grows as I/O packs are added to the control

system, enabling an overall control system frame rate of 10 ms in simplex, dual, or

triple redundant configuration. Some process sub-systems require even more

performance; therefore, the local processors in each I/O pack run algorithms at

higher rates as required for the application.

Redundancy

Every application has different requirements for redundancy depending on the

importance of the process. Mark VIe provides a wide range of redundancy options

that can be supplied in virtually any combination and mounted local or remote. Some

of these redundancy options include:

• Power sources and supplies single, dual, and triple

• Controllers (main processor) single, dual, and triple

• I/O network redundancy single, dual, and triple

• I/O packs per terminal board single, dual, and triple

• Ethernet Ports / I/O pack single or dual

System Architecture

Controllers are continuously online and read input data directly from IONet. Dual

redundant systems transmit inputs from one or redundant I/O packs on dual IONets

to dual controllers. Outputs are transmitted to an output I/O pack that selects either

the first healthy signal or the signal of choice. Three output packs can be provided to

vote output signals for mission-critical field devices.

Dual redundant systems can be configured for single, dual, and triple sensors. Their

dual internal networks and controllers keep the process online if a controller or

power supply fails. Triple redundant systems are available to protect against soft or

partial failures of devices that continue to run but with incorrect signals/data.

These systems out vote a failed component with a 2-out-of-3 selection of the signal.

Application software in all three controllers runs on the voted value of the signal

while diagnostics identify the failed device. These sophisticated diagnostics

minimize the mean-time-to-repair (MTTR) while the on-line repair capability

maximizes the mean-time-between-forced-outages (MTBFO). Field sensors for these

systems can be single, dual, or triple.

A second controller can be provided to separate the application software for different

pieces of equipment. For example, a core engine control for an air-fuel governor can

run in one controller while a second controller can be dedicated to auxiliary control.

Note Every I/O pack communicates directly on IONet, which enables each I/O pack

to be replaced individually without affecting any other I/O in the system. Also, the

I/O pack can be replaced without disconnecting any field wiring.

I/O Interface

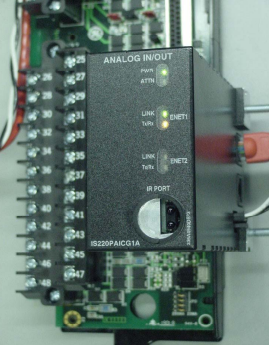

One or multiple I/O packs are mounted on each board to digitize the sensor signal,

perform algorithms, and communicate with a separate controller that contains the

main processor. I/O packs have a local processor board that runs a QNX operating

system and a data acquisition board that is unique to the type of input device. Local

processors run algorithms at faster speeds than the overall control system.

An on-board temperature sensor

provides continuous monitoring of

the environment in remote

locations.

An infrared transceiver is useful for low-level diagnostics. I/O values can be

monitored, I/O pack host/function names can be programmed, and error statuses can

be checked. This requires a Windows®-based diagnostic tool on a laptop or a

handheld computer.

• Dual 100 MB Ethernet ports

• 100 MB full duplex ports

• Online repair per I/O pack

• Operation -30°C to 65°C (-22 °F to 149 °F)

• Accuracy -30°C to 65°C (-22 °F to 149 °F)

• I/O packs rated Class 1, Div. 2

• Ambient temperature sensor

• LEDs: power status and attention

• LEDs: Ethernet link-connected and communication-active

• LEDs: application-specific

• Processor: 32-bit RISC CPU 266 mHz

• Infrared Transceiver: Low level diagnostics, monitor I/O,

set host/function names, error status

• Power: 28 V dc (typical)

• Internal solid-state circuit breaker and soft start

The I/O Processor contains a temperature sensor that is accurate to within ±2°C

(±3.6 °F). Detection of an excessive temperature generates a diagnostic alarm, and

the logic is available in the database (signal space) to facilitate additional control

action or unique process alarm messages. In addition, the temperature is

continuously available in the database.

A power supply provides a regulated 28 V dc power feed to each I/O pack. The

negative side of the 28 V dc is grounded through the I/O pack metal enclosure and its

mounting base. The positive side has solid-state circuit protection built-into the I/O

pack with a nominal 2 A trip point. Online repair is possible by removing the

28 V dc connector, replacing the I/O pack, reinserting the power connector, and

downloading software from the software maintenance tools.

Note Every I/O pack communicates directly on IONet, which enables each I/O pack

to be replaced individually without affecting any other I/O in the system. Also, the

I/O pack can be replaced without disconnecting any field wiring

Terminal Blocks

Signal flow begins with a sensor connected to a terminal block on a board. There are

two types of boards available. T-type boards contain two 24 point, barrier-type,

removable, terminal blocks. Each point can accept two 3.0 mm2

(#12AWG) wires

with 300 V insulation per point with spade or ring type lugs. In addition, captive

clamps are provided for terminating bare wires. Screw spacing is 9.53 mm (0.375

inch) minimum, center-to-center.

A shield strip is provided next to each block, which is actually the left-hand side of

the metal base where the board is mounted. Wide and narrow boards are arranged in

vertical columns of high and low-level wiring that can be accessed from top and/or

bottom cable entrances. An example of a wide board is a board that contains

magnetic relays with fused circuits for solenoid drivers. T-type boards are normally

surface mounted, but can also be DIN-rail mounted.

S-type boards have one I/O pack for simplex and dual redundant systems. They are

half the size of T-type boards and are DIN-rail or surface mounted. Two versions of

the boards are available, H1 and H3. H1 boards have fixed terminal blocks, and H3

boards have removable terminal blocks. A H2 version is available for mounting of

custom blocks such as spring-cage or insulation displacement.

S-type boards have box type terminal blocks that accept one 3.0 mm2

(#12AWG)

wire or two 2.0 mm2

(#14AWG) wires with 300 V insulation per point. Screw

spacing is 5.08 mm (0.2 inch) minimum, center-to-center. A shield strip is provided

to the left of each block. It can be connected to a metal base for immediate grounding

or floated to allow individual ground wires from each board to be wired to a

centralized, cabinet ground strip.

I/O Types

General purpose I/O is used for both turbine applications and process control.

Turbine-specific I/O is used for direct interface to the unique sensors and actuators

on turbines. This reduces or eliminates a substantial amount of interposing

instrumentation. As a result, many potential single point failures are eliminated in the

most critical area for improved running reliability and reduced long-term

maintenance. Direct interface to the sensors and actuators also enables the

diagnostics to directly interrogate the devices on the equipment for maximum

effectiveness. This data is used to analyze device and system performance. Also,

fewer spare parts are needed.

I/O Type - General Purpose Board

Redundant

Packs/Boards

24 DI (125 V dc, group isolated) 1 ms SOE TBCIH1 1 or 2 or 3

24 DI (24 V dc, group isolated) 1 ms SOE TBCIH2 1 or 2 or 3

24 DI (48 V dc, group isolated) 1 ms SOE TBCIH3 1 or 2 or 3

24 DI (115/230 V ac, 125 V dc, point isolated) 1 ms SOE on 125 V dc TBCIH1 1 or 2 or 3

24 DI (24 V dc, point isolated) TBCIH2 1 or 2 or 3

24 DI (24 V dc, group isolated) STCIH1 1

12 C mechanical relays w/6 solenoids, coil diagnostics (115/230 V ac, 24/125 V dc) TRLYH1B 1 or 3

12 C mechanical relays w/6 solenoids, voltage diagnostics (115/230 V ac, 125 V dc) TRLYH1C 1 or 3

12 C mechanical relays w/6 solenoids, voltage diagnostics (24 V dc) TRLYH2C

6 A mechanical relays for solenoids, solenoid impedance diagn. (24/125 V dc) TRLYH1D 1 or 3

12 A solid-state relays/inputs (115/230 V ac) TRLYH1E 1 or 3

12 A solid-state relays/inputs (125 V dc) TRLYH2E 1 or 3

12 A solid-state relays/inputs (24 V dc) TRLYH3E 1 or 3

36 mechanical relays, 12 voted form A outputs TRLYH1F 3

12 fused branches WPDFH1A

36 mechanical relays, 12 voted form B outputs TRLYH2F 3

12 fused branches WPDFH2A

10 AI (V/I inputs) and (2AO (4-20/0-200 mA outputs) TBAIH1C 1 or 2 or 3

10 AI (V/I inputs) and (2AO (4-20/0-200 mA outputs) STAIH1A 1 or 2 or 3

16 AO (4-20 mA outputs) 8 per I/O pack TBAOH1C 1 or 2

8 AO (4-20 mA outputs) STAOH1A 1

12 thermocouples TBTCH1B 1 or 2 or 3

24 thermocouples (12 per I/O pack) TBTCH1C 1 or 2

12 thermocouples STTCH1A 1

16 RTDs 3 wires/RTD (8 per I/O pack) TRTDH1C 1 or 2

8 RTDs 3 wires/RTD SRTDH1A 1

6 serial ports for I/O drivers RS-232, RS422, RS485 SSCAH1A 1

10/2 analog I/O - HART communications SHRAH1A 1

PROFIBus communications SPIDH1A 1

I/O Type - Turbine Board

Redundant

Packs/Boards

Mixed I/O: 4 speed inputs/pack, synchronizing, shaft V/I monitor TTURH1C 1 or 3

2 servo channels: up to 3 coils, 4 LVDTs/channel, includes excitation TSVCH1A 1 or 3

8 vibration (seismic, proximity, accel.), 4 position, 1 reference probe, buffered out TVBAH1A 1 or 2 or 3

Controller

Features

• Single board including:

Main Processor

Control Network Communications - Ethernet

IO Network Communications – Ethernet

USB and COM ports

• Processor: Freescale 8349, 667MHz

• Operating system: QNX

• Base mounting

• Status LEDs

Environment

• Operating temperature 0°C to +65 °C

• No fans required

Features

• Single board including:

Main Processor

Control Network Communications - Ethernet

IO Network Communications – Ethernet

USB and COM ports

• Processor: Freescale 8349, 667MHz

• Operating system: QNX

• Base mounting

• Status LEDs

Environment

• Operating temperature 0°C to +65 °C

• No fans required

Mark VIe Controller

The single-board controller is a

compact and flexible design for

processing and network

communications.

The controller is a single board, which is base-mounted in the cabinet. For dual and

triple redundant systems, a second and third board can be mounted adjacent for a

compact packaging arrangement. An 8349, 667 MHz processor is provided with a

QNX operating system. The board is powered by 18-36 V dc, 12 watt source.

This rugged design is rated for an operating range of 0 to 65°C (32 to 149 °F) to

match the maximum operating temperature of the I/O modules. Also, it does not

require any cooling fans even at maximum temperature, and is suitable for NFPA

Class 1, Div. 2 applications.

Each controller has three 100 MB Ethernet drivers for the IONet, so that each

controller can communicate with up to three network switches. In redundant systems,

this allows each controller to monitor redundant inputs directly and compare them

for any potential discrepancies. Connectors are color-coded and labeled to simplify

maintenance.

Controllers also have two Ethernet drivers for the control network to communicate

peer-to-peer with other Mark VI, Mark VIe, and EX2100 generator excitation

controls, as well as operator and maintenance stations. Controllers can be

synchronized between units or to a local or remote time source for accurate plantwide sequence of events monitoring.

Switches manage the

communication traffic to

eliminate collisions and

increase network determinism

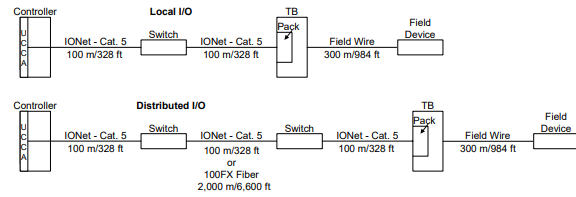

Communication between the controller and the I/O packs is performed with the

internal IONet. This is a 100 MB Ethernet network available in non-redundant, dual

redundant, and triple redundant configurations. Ethernet Global Data (EGD) and

other protocols are used for communication. EGD is based on the UDP/IP standard

(RFC 768). EGD packets are broadcast at the system frame rate from the controller

to the I/O packs, which respond with input data.

IONet conforms to the IEEE 802.3 standard. It is supplied as 100BaseTx and

100BaseFx (fiber) for greater distances, noise rejection, lightning immunity, and

ground immunity. A star topology is used with the controller on one end, a network

switch in the middle, and I/O packs at the end

Maximum IONet Distances Including Field Devices

Industrial grade switches are used for the IONet that meet the codes, standards,

performance, and environmental criteria for industrial applications including an

operating temperature of -40°C to 85°C (-40 °F to 185 °F) and Class 1, Div. 2.

Switches have provision for redundant 10 to 30 V dc power sources (200/400 mA)

and are mounted on a DIN-rail. LEDs indicate the status of the IONet link, speed,

activity, and duplex.

100BaseTx 100BaseFx

IEEE specification 802.3u 802.3u

Wire speed 100 Mbps 100 Mbps

Cable type UTP Cat. 5 Fiber (multi-mode)

Connector type RJ-45 SC

Maximum length of a segment at full-duplex 100 m/328 ft 2 km/6,600 ft

Maximum taps per segment 2 2

Maximum I/O packs per network 199 199

Maximum number of switches 2 2

Topology Star Star

Operator and Maintenance Tools

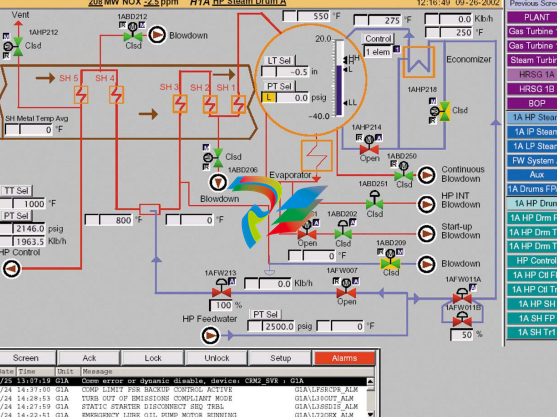

Operator Interface

The operator interface is commonly referred to as the Human-Machine Interface

(HMI). It is a computer with a Microsoft® Windows-based operating system,

client/server capability, a CIMPLICITY® graphics display system, and software

maintenance tools (ToolboxST). It can be applied as:

• Primary operator station for one unit or the entire plant

• Maintenance station gateway

• Engineers station

• Gateway for communications

All local and remote data in

the Mark VIe is accessible for

screens with high-resolution

time tags for alarms and

events.

The HMI can be re-initialized or replaced with the process running with no impact

on the control system. It communicates with the main processor board in the Mark

VIe controller(s) through the control network Unit Data Highway (UDH) and to

third-party control and monitoring systems through the information network Plant

Data Highway (PDH).

System (process) alarms for fault conditions are time-tagged at frame rate in the

controller(s) and transmitted to the HMI alarm management system. System events

are time-tagged at frame rate, and sequence of events (SOE) for contact inputs are

time-tagged at 1 ms in the I/O packs. Alarms can be sorted according to ID,

Resource, Device, Time, and Priority. Operators can add comments to alarm

messages or link specific alarm messages to supporting graphics.

A standard alarm/event log stores data for 30 days and can be sorted in chronological

order or according to the frequency of occurrence. In addition, a trip history is

provided that stores the key control parameters and alarms/events for the last 30

trips. This includes up to 200 alarms, 200 events, 200 SOE messages, and analog

data before and after the trip.

Data is displayed in English or Metric engineering units with a one-second update

rate and one second to repaint a typical display graphic. Operator commands can be

issued to increment/decrement a setpoint, or a numerical value can be entered for a

new setpoint.

Security for HMI users is important to restrict access to certain maintenance

functions, such as editors and tuning capability, and to limit certain operations.

A system called User Accounts is provided to limit access or use of particular HMI

features.

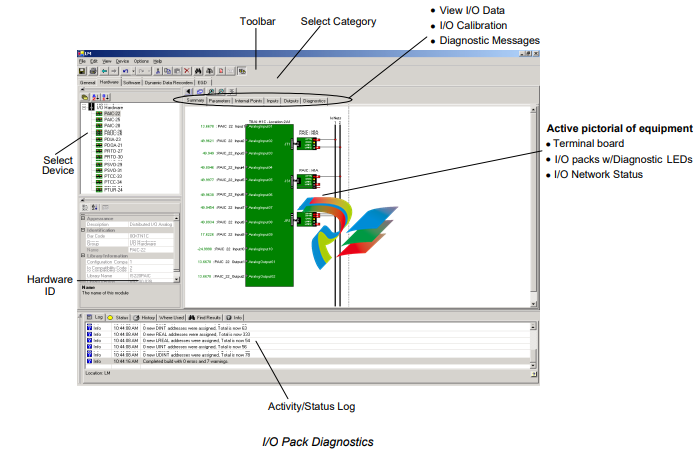

Software Maintenance Tools (ToolboxST)

The Mark VIe is a fully programmable control system. Application software is

maintained by factory software automation tools that select proven GE control and

protection algorithms and integrate them with the I/O, sequencing, and displays for

each application. Multiple block libraries are provided with general-purpose blocks,

math blocks, macros (user blocks), and application-specific blocks.

Changes to the application software can be made with multi-level password

protection and downloaded to the controller(s) while the system is running without

rebooting the main processors. In redundant control systems, the application

software in each controller is identical, and is represented as a single program to

maintenance personnel. Downloads of changes are automatically distributed to the

redundant controllers by the control system, and any discrepancies between the

controllers are monitored by diagnostics. All application software is stored in the

controller(s) in non-volatile memory.

Application software is run sequentially, and dynamic data displays in function block

and ladder diagram formats. Maintenance personnel can add, delete, or change

analog loops, sequencing, I/O assignments, and tuning constants. To simplify

editing, data points can be selected, dragged, and dropped on the screen from one

block to another. Points can also be dragged from the application software diagrams

onto trends. Other features include Boolean (digital) forcing, analog forcing, and

trending at the rate the application software is running, frame rate.

Application software documentation is created directly from source code and can be

compiled and printed at the site. This includes the application software diagram, I/O

assignments, the settings of tuning constants, and such. The software maintenance

tools are available for use in the HMI or as a separate software package on a

Windows-based computer.

Diagnostics

High/low (hardware) limit checking is provided for each analog input. These limits

are not configurable, and are selected to be outside the normal operating range but

inside the linear hardware operational range (before the hardware reaches saturation).

Diagnostic messages for hardware limit checks and all other hardware diagnostics

for the board can be accessed with the software maintenance tools. A composite

diagnostic alarm state is provided in the database for each I/O pack, and a separate

logic state is provided to indicate a high/low (hardware) limit fault of any analog

input or the associated communications for that signal.

Diagnostic and system (process) alarms are time-stamped in the controller(s) and

transmitted to operator and maintenance stations. Communication links to a plantdistributed control system (DCS) can contain both the software (system) diagnostics

and composite hardware diagnostics.

Diagnostic LEDs are provided on I/O packs as previously shown for the Analog I/O

pack. Standard LEDs indicate: power status, attention (abnormality detected),

Ethernet link connected, and Ethernet link communicating. LEDs on discrete I/O

packs also indicate the status of each point. All boards feature an electronic ID that

contains the board name, revision, and a unique serial number. When power is

applied to the I/O processor, it reads the ID of the terminal board, application board,

and itself. It then uses this information for a start permissive, diagnostics, and system

asset management. Since the terminal boards can be mounted remote at the

equipment, local temperature sensors monitor the temperature at each I/O pack.

Excessive temperature causes an alarm message. The alarm state and current

temperature value are available for display and for use in the application software

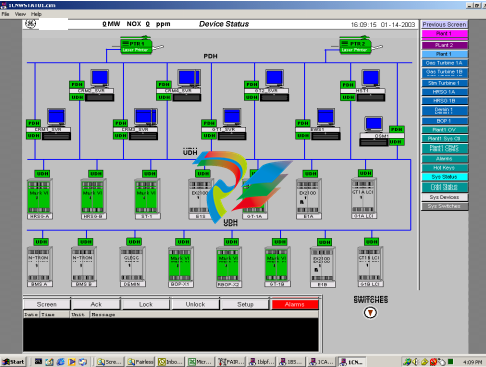

Plant level control systems integrate the diagnostic data from the individual turbine

and generator controls with the overall plant. This allows maintenance personnel to

quickly identify the defective control node, switch, or station and locate the

particular device needing service.

Network Diagnostics for:

z Operator Stations

z Maintenance Stations

z Engineers Stations

z Switches on:

- Plant Data Highway

- Unit Data Highway

- IONet

z Control Nodes

- Boards Within Nodes

- I/O Packs