STOBERDESCRIZIONE Il regolatore indicatore Serie SG65 è adatto al controllo di variabili fisiche quali temperatura, pressione e livello di liquidi, gas e vapori negli impianti industriali o di processo. Il valore misurato della variabile fisica viene

Instructions, National Electrical Code and any additional local codes”, or the equivalent.

Suitable for use on a circuit capable of delivering not more than 10 kA rms. Symmetrical

Amperes, 480 Volts Maximum” when Protected by RK1 Class Fuses as specified in the

chapter technical data.

Subject to technical changes without prior notification which changes serve to

improve the devices. This documentation is purely a product description. It does

not represent promised properties in the sense of warranty law.

1.2 Software

Use of the POSITool software The POSITool software package can be used to select an application, adjust parameters

and signal monitoring of the 5th generation of STÖBER inverters. The functionality is

specified by the selection of an application and the transmission of these data to an

inverter.

The program is the property of STÖBER ANTRIEBSTECHNIK GmbH + Co. KG and is

protected by copyright. The program is licensed for the user.

The software is provided exclusively in machine-readable format.

The customer receives from STÖBER ANTRIEBSTECHNIK GmbH + Co. KG a nonexclusive right to use the program (license) if the program was obtained legally.

The customer has the right to utilize the program for the above stated activities and

functions and to make and install copies of the program, including one backup copy, for

support of said utilization.

The conditions of this license apply to all copies. The customer is obligated to place the

copyright note and all other ownership notes on every copy of the program.

The customer is not authorized to use, copy, change or pass on/transmit the program for

reasons other than those covered by these conditions; the customer is also not

authorized to convert the program (reverse assembly, reverse compilation) or compile

the program in any other manner, or to sublicense, rent or lease the program.

Product maintenance The obligation to perform maintenance applies to the two last current program versions

prepared and released for use by STÖBER ANTRIEBSTECHNIK GmbH + Co. KG.

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG can either correct program errors or

provide a new program version. The choice is up to STÖBER ANTRIEBSTECHNIK

GmbH + Co. KG. If, in individual cases, the error cannot be corrected immediately,

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG will provide an intermediate solution

which, if necessary, requires adherence by the user to special operating regulations.

The claim to error correction only exists when reported errors are reproducible or can be

recorded by machine-made outputs. Errors must be reported in reconstructable form

giving useful information for error correction.

The obligation to correct errors is invalidated for such programs which the customer

changes or manipulates unless the customer can prove when reporting the error that the

manipulation is not the cause of the error.

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG is obligated to keep the currently valid

program versions in a specially protected place (fire-resistant data safe, safety deposit

box at a bank).

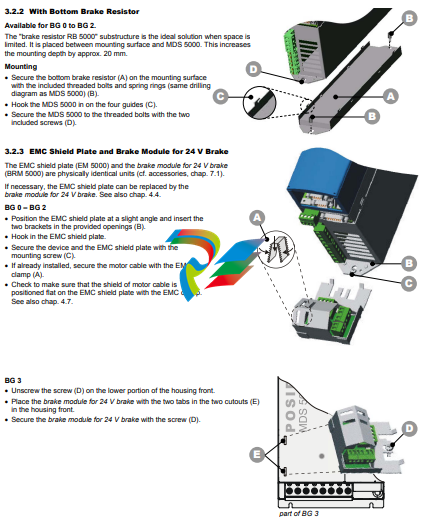

3.2.2 With Bottom Brake Resistor

Available for BG 0 to BG 2.

The "brake resistor RB 5000" substructure is the ideal solution when space is

limited. It is placed between mounting surface and MDS 5000. This increases

the mounting depth by approx. 20 mm.

Mounting

• Secure the bottom brake resistor (A) on the mounting surface

with the included threaded bolts and spring rings (same drilling

diagram as MDS 5000) (B).

• Hook the MDS 5000 in on the four guides (C).

• Secure the MDS 5000 to the threaded bolts with the two

included screws (D).

3.2.3 EMC Shield Plate and Brake Module for 24 V Brake

The EMC shield plate (EM 5000) and the brake module for 24 V brake

(BRM 5000) are physically identical units (cf. accessories, chap. 7.1).

If necessary, the EMC shield plate can be replaced by the

brake module for 24 V brake. See also chap. 4.4.

BG 0 – BG 2

• Position the EMC shield plate at a slight angle and insert the

two brackets in the provided openings (B).

• Hook in the EMC shield plate.

• Secure the device and the EMC shield plate with the

mounting screw (C).

• If already installed, secure the motor cable with the EMC

clamp (A).

• Check to make sure that the shield of motor cable is

positioned flat on the EMC shield plate with the EMC clamp.

See also chap. 4.7.

BG 3

• Unscrew the screw (D) on the lower portion of the housing front.

• Place the brake module for 24 V brake with the two tabs in the two cutouts (E)

in the housing front.

• Secure the brake module for 24 V brake with the screw (D)

Installation of Accessories

Only specialized personnel who are qualified for this task may install accessories (cf. chap. 7). Suitable measures must be

provided against damage by electrostatic discharging (in accordance with DIN EN 50082-2). Before installation, the device must