STOBERDESCRIZIONE Il regolatore indicatore Serie SG65 è adatto al controllo di variabili fisiche quali temperatura, pressione e livello di liquidi, gas e vapori negli impianti industriali o di processo. Il valore misurato della variabile fisica viene

• Connect the shield of the control lines on one side with reference ground of the reference value source (e.g., PLC or CNC).

• Shield, and, if necessary, twist reference value lines before installing.

4.2 RCD (Residual Current Protective Devices)

Network phases and neutral conductors are connected with the protective conductor via Y capacitors. When network voltage is

applied, a leakage current flows over these capacitors to the protective conductor. The greatest leakage current occurs during a

malfunction (asymmetric feedin via only one phase) and during power-on (sudden change in voltage). The maximum leakage

current due to asymmetric power feedin is 40 mA (network voltage of 400 V) for MDS inverters.

If RCD circuit breakers are necessary, the problem of power-on and off can be alleviated by using selective RCD circuit

breakers (switch-off delay) or RCD circuit breakers with increased tripping current (e.g., 300 or 500 mA). Only all-current

sensitive RCD circuit breakers may be used. Operation of several devices on one RCD circuit breaker is not recommended.

4.3 Power Connection

Protection via line circuit breakers in accordance with the values listed in chap. 2 (tripping characteristic C, in accordance with

EN 60 898) or suitable, delayed safety fuse.

Use class RK1 fuses for UL conformance: Class RK1 (e.g., Bussmann KTS-R-xxA / 600 V)

POSIDRIVE® MDS 5000 – Mounting Instructions STÖBER ANTRIEBSTECHNIK

4. Electrical Installation

16

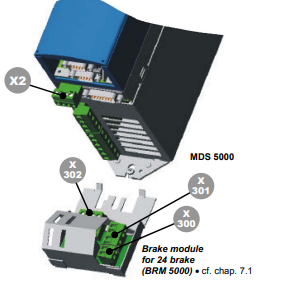

4.4 Brake Module for 24 V Brake

The relay in the basic device for brake control is equipped with hardgold contacts. This relay is designed for control of an

electro-magnetic brake. The brake module for 24 V brake is required for control of a 24 V brake (BRM 5000). A thermally

monitored and short-circuit-proof, electronic semi-conductor switch is available for switching the brake. When Brake module for

24 V brake is placed between relay and brake, the integrated filter suppresses the switch-off reactions. This also increases the

lifespan of the relay contacts.

For a 230 VAC brake we also recommend control via

a coupling relay and not directly via the existing relay.

Installation

• Connect terminal X302 with terminal X2

(for connection cable, see chap. 4.7.2).

• Connect the external 24 V to the power supply of the

brake on X300 an (for pin allocation, see chap. 5.3).

• The brake and thermal contact lines installed in the motor

cable are connected to X301 (for pin allocation, see chap. 5.3).

POSIDRIVE® MDS 5000 – Mounting Instructions STÖBER ANTRIEBSTECHNIK

4. Electrical Installation

17

4.5 DC Link Coupling

If you are using axes in a plant which operate in a network of generators and motors, the DC link coupling (DC coupling) can be

advantageous. When the DC-coupling is used, the excess energy of other axes is made available as drive power instead of

converting this excess power into heat with a brake resistor. Remember that you will need a brake resistor which can absorb the

power peaks when all drives in the DC-link network brake at the same time.

DANGER

Danger of damage to devices! When single-phase and three-phase devices are coupled,

the single-phase devices will be destroyed. Use only three-phase devices for the DC link

coupling!

CAUTION

Danger of damage to devices! When one device within the DC-link coupling network fails,

the complete DC-link coupling network must be disconnected from the power network since

other devices in the DC-link coupling network may be damaged. Be sure to adhere to the

wiring of the ready-for-operation relay shown in chapter 4.5.1 (X1.1 and X1.2). When a

failure occurs, replace all devices of one group.

NOTE

Please note that the parameter A38 DC power-input must be set before the DC link

coupling will function correctly.

Group 1: A38 = 0: inactive

Group 2 and 3: A38 = 1: active

For more details, also see the description of the parameter.

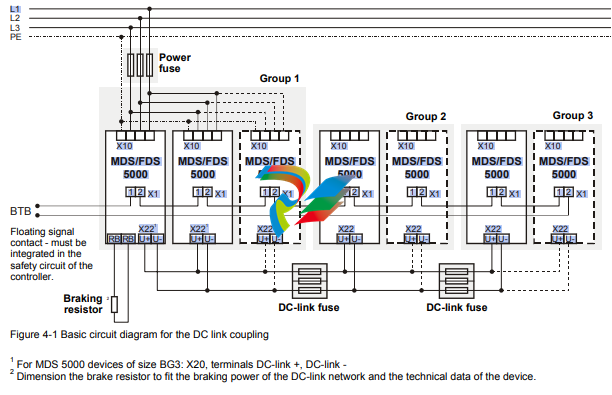

4.5.1 Basic Circuit Diagram

The following diagram shows the basic circuiting of the DC-link coupling. The inverters can be coupled together in up to three

groups. The table in chapter 4.5.2 shows the possible combinations. The combination determines the types of power fuse and

DC-link fuse.

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

X10 X10 X10 X10 X10 X10 X10

X1 X1 X1 X1 X1 X1 X1

X221

X221

X22 X22 X22 1

X22 X22

RB RB U+ U+ U+ U+ U- U- U- U- U+ U+ U+ U- U- U11 1 1 22 2 2 111 222

L1

NOTE

The certified version of the safety function is available for designs BG 0 to BG 2 as per EN

954-1 category 3. You will find the certificate under www.stoeber.de

The ASP 5001 may only be installed and repaired by STÖBER ANTRIEBSTECHNIK. This

is why you should include installation in the inverter with your order of the ASP 5001.

NOTE

When certified use is required, the inverter must be installed in a switching cabinet with a

protection rating of IP54.