STOBERDESCRIZIONE Il regolatore indicatore Serie SG65 è adatto al controllo di variabili fisiche quali temperatura, pressione e livello di liquidi, gas e vapori negli impianti industriali o di processo. Il valore misurato della variabile fisica viene

be disconnected from the power and, with the MDS 5xxx/L series, the 24 V power must be turned off. Remember the discharge

times (≥ 5 min.) for the DC link.

CAUTION

Immediately after the power is turned off, the DC link is still charged. Wait > 5 min. for the DC link to discharge

after turning off the power voltage. To prevent damage to device and accessory parts, install the accessory

afterwards.

CAUTION

Danger of electrostatic charges damaging the PCB!

Perform potential equalization before you touch a PCB (option module 1 and 2).

3.3.1 Option module 1 (fieldbus)

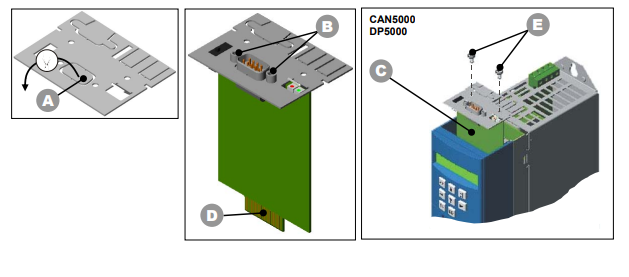

3.3.1.1 CANopen DS-301 (CAN5000) / PROFIBUS DP-V1 (DP5000)

Installation is the same for both modules.

• Make sure that the device is without power. Wait ≥ 5 min. for the DC link capacitors to discharge after turning off the power

supply voltage.

• Disconnect the cover plate by removing the two screws (E).

• Remove the prepunched area (A) for the sub D plug connector on the plate.

• Mount the plate on the board with the included UNC bolts (B).

• Slide the fieldbus board (C) with the gold-contacted terminal surfaces (D) into the black terminal block.

CAUTION

Be sure not to touch the gold contact surface with your fingers (danger of fouling and corrosion).

• Check correct position of the board.

• Secure the board with the two included screws (E).

• Then apply included labels (nameplate and adhesive label for switch setting (CAN)) to the cover plate.

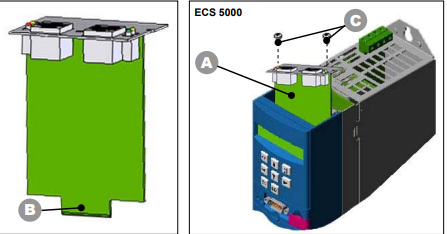

3.3.1.2 EtherCAT (ECS 5000)

• Make sure that the device is without power. Wait ≥ 5 min. for the DC link capacitors to discharge after turning off the power

supply voltage.

• Disconnect the cover plate by removing the two screws (C).

• Slide the EtherCAT board (A) with the gold-contacted terminal surfaces (B) into the black terminal block.

CAUTION

Be sure not to touch the gold contact surface with your fingers (danger of fouling and corrosion).

• Check correct position of the board.

• Secure the board with the two included screws (C).

• Then apply included labels (nameplate) to the cover plate.

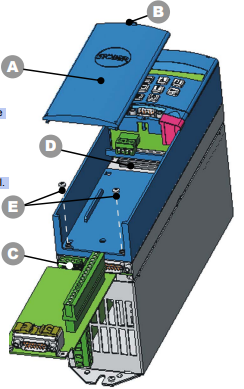

3.3.2 Option module 2 (terminals)

• Standard (SEA 5000, SEA 5001)

• Expanded (XEA 5001)

• Resolver (REA 5000)

Installation is the same for all modules.

• Make sure that the device is without power.

• Before installation, remove the blue plastic cover (A) below the serial interface

(terminal X3).

• Make sure that the device is without power.

• Unlock the snap-on lock (B) directly below terminal X3 and, on the snap-on

lock, pull the cover towards the front.

• To completely unhook the cover, pull this in the direction of the operator panel.

• Push the I/O terminal module with the gold-contacted terminal surface (C)

into the black terminal block (D).

CAUTION

Be sure not to touch the gold contact surface with your fingers

(danger of fouling and corrosion).

• Check correct position of the board.

• Secure the board with the two included screws (E).

• Now hook the plastic cover (A) with the two catches into the plastic housing.

• Press the plastic cover (A) against the plastic housing until the snap-on lock

(B) snaps in.

POSIDRIVE® MDS 5000 – Mounting Instructions STÖBER ANTRIEBSTECHNIK

4. Electrical Installation

15

4 ELECTRICAL INSTALLATION

This chapter gives you complete information on the subject of electrical installation.

Only specialized personnel who are qualified for this task may install, commission and control the device.

4.1 EMC

This chapter contains general information on EMC-suitable installation. These are only recommendations. Depending on the

application, the ambient conditions and the legal requirements, measures in addition to the following recommendations may be

required.

• Mount device or Bottom Brake Resistor on conductive surface (unpainted).

• Install the power cables in spatially separately from the signal lines (encoder, analog/digital signal lines).

• Use only shielded cable for motor lines (corresponding cabels can be ordered from STÖBER ANTRIEBSTECHNIK.).

• Apply shield of the motor cable over a large surface in the immediate vicinity of the MDS 5000. The EMC shield plate (EM

5000) for mounting on the bottom of the device is available as an accessory (see chap. 3.2.3 and chap. 7.1).

• With asynchronous machines, apply the shield to the terminal block over a large surface (e.g. PG shield screw connection).

• Use output deraters for motor lines > 50 m.

• When an additional transfer plug connector is to be installed in the motor cable, the cable shield may not be interrupted.

• When the brake line is installed in the motor cable, the brake line must be shielded separately.

• When the length of the cable for connection of a brake resistor is longer than 30 cm, this must be shielded and the shield

must be applied over a large surface in the immediate vicinity of the MDS 5000.