schneiderSystem Planning and Installation Guide for Model PC-E984-3811385 & PC-E984-385D

Executive Functionalitv

381 E

Executive ID of 813 (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT and

CKSM.

Two standard Modbus ports, Time-of-Day clock, Peer Cop, Local I/O only.

385E

Executive ID of 81C (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT and

MSTR.

(MSTR is the user interface to Modbus Plus. It replaces the CKSM function

and uses its opcode.

One Modbus port, One Modbus Plus Port, Time-of-Day clock, Peer Cop,

Local I/O only.

Module Housings

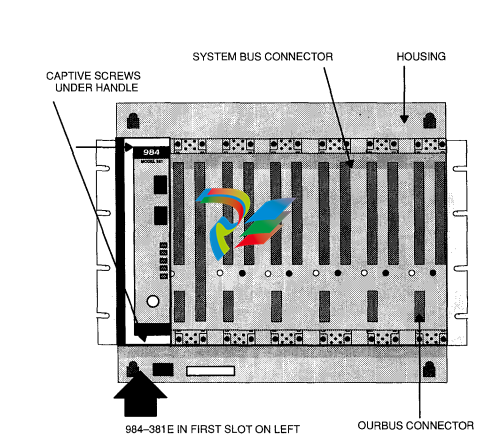

The Model 381 E/385E system uses Modicon 800 series housings for its controller

and I/O modules; specifically, a 19” primary housing with a seven module capacity

or a 27” primary housing with an eleven module capacity.

Primary Enclosure - With the single width Model “E” controller in your primary enclosure, the 19’ and 27” primary enclosures will accommodate up to 6 or IO I/O

modules, respectively.

Secondary Enclosure -The secondary housing will accommodate a one and onehalf wide P810, P800 or P884 auxiliary power supply if a power supply expander

is required and as many I/O modules as there is room remaining.

Specifically, the standard 19” or 27” secondary housings will accommodate five or

nine I/O modules along with a one and one-half wide (two-slot) auxiliary power

supply and a full seven or eleven I/O modules without the power supply.

The 1 g-inch primary housing with controller is shown in Figure 2. For simplicitys ’

sake, the 27” housing is not shown in this manual except as required in the illustration on panel mounting dimensions.

Construction

The Model “E” controller is housed in a rugged metal chassis designed to withstand specified temperature and humidity extremes as well as vibration, shock,

and ambient atmospheric conditions consistent with the “factory floor.”

The primary housing employs a shielded backplane which provides for internal

communications within the housing. The backplane protects the internal system

communications from both electromagnetic (EMI) and radio frequency interference

(RFI).

Captive screws secure all modules in the housings and they should be used to insure good electrical contact between the connector at the rear of the module and

backplane in the housing. Key pin protection is also available.

User memory is backed up by a lithium battery which has a one year service life.

It will hold-up for 14 days after the BAT LOW indicator comes on. The batterys ’

installed but unused service life is rated at one year, with a five year shelf life.

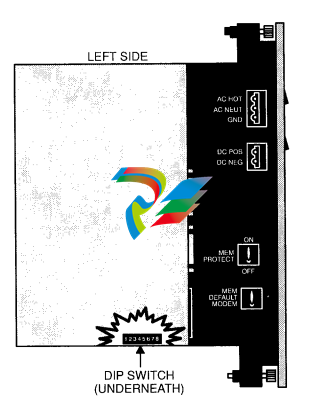

A manually operated memory-protect toggle switch prevents accidental access to

the users ’ program. This switch is located on the left side of the unit, above the 3

position communications toggle switch (see Figure 3).

Power Supply Function (AC and DC)

The Model 381 E/385E and 385D systems ’ controller module comes with a built-in

I/O power supply.

The Model “E” Controllers run on 97 through 276 VAC (47 to 63 Hertz) and 24Vdc.

As shown on Figure 3, Once connected, AC power is then switched ON/OFF with

a front panel rocker switch.

The PLC will also operate continuously on 24Vdc as its an alternate or exclusive

source. Figure 3 shows a primary power input connector for a customer supplied

24Vdc source. Once connected, DC power is then switched ON/OFF with a front

panel rocker switch.

Figure 3 Wiring Connectors, Communications and Memory Switches

The 385D input can range from 105 to 150 VDC with the nominal at 125 VDC controlled by a front panel rocker switch. The 24 VDC option is also available.

Note The primary power DC input feature was not designed, nor is it

suitable as an automatic battery backup provision in the event of an AC

outage. This is because the controllers ’ externally sourced DC input

joins with the AC.sourced, internally produced DC. At any given time,

the Controller is taking from the higher of the two DC voltage sources if

there is as little as a 1 V differential. The consequence of this would be

to draw down the DC battery if there were an extended period(s) of reduced AC voltage supply.

8 Controller Introduction

If you want a backup alternative, one could be configured from a user-supplied

DC power supply with its own backup batten and charger combination along with

appropriate monitoring provisions.

Communications Processing Function

The Models 381 E/385E/385D have Modbus capability for data transfer and remote

programming. Through this port, communication processing on the CPU board

can be linked from the controller to supervisory and programming devices such as

a host computer or Modicon programmer. The Modbus port allows you to schedule one Modbus service per scan. The Model 381 has a second Modbus port

which allows you to incorporate your controller into the Modbus network and still