WATLOWEZ-ZONE® PMUser’s GuidePID Controller Models

seal, simply slide together until the gasket is

compressed.

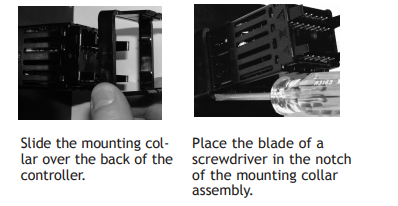

3. For a NEMA 4X (UL50, IP65) seal, alternately

place and push the blade of a screwdriver

against each of the four corners of the mounting collar assembly. Apply pressure to the face

of the controller while pushing with the screwdriver. Don't be afraid to apply enough

pressure to properly install the controller. The seal system is compressed more by mating

the mounting collar tighter to the front panel (see pictures above). If you can move the

case assembly back and forth in the cutout, you do not have a proper seal.

The tabs on each side of the mounting collar have teeth that latch into the ridges on the

sides of the controller. Each tooth is staggered at a different depth from the front so that

only one of the tabs, on each side, is locked onto the ridges at a time.

Note:

There is a graduated measurement difference between the upper and lower half of the

display to the panel. In order to meet the seal requirements mentioned above, ensure

that the distance from the front of the top half of the display to the panel is 16 mm

(0.630 in.) or less, and the distance from the front of the bottom half and the panel is

13.3 mm (0.525 in.) or less.

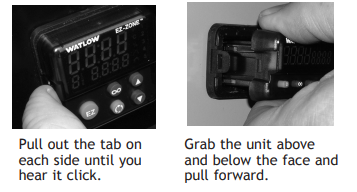

Removing the Mounted Controller from Its Case

From the controller's face, pull out the tabs on each side until you hear it click

2. On a PM6 control once the sides are released grab the unit above and below the face with

two hands and pull the unit out. On the PM4/8/9 controls slide a screwdriver under the

pry tabs and turn.

WARNING! ç

• This equipment is suitable for use in class 1, div. 2, Groups A, B, C and D or Non-Hazardous

locations only. Temperature Code T4A.

• WARNING – EXPLOSION HAZARD. Substitution of component may impair suitability for class 1,

div. 2.

• WARNING – EXPLOSION HAZARD. Do not disconnect equipment unless power has been

switched off or the area is known to be nonhazardous.

Returning the Controller to its Case

1. Ensure that the orientation of the controller is correct and slide it back into the housing.

Note:

The controller is keyed so if it feels that it will not slide back in do not force it. Check the

orientation again and reinsert after correcting.

2. Using your thumbs push on either side of the controller until both latches click.

Chemical Compatibility

This product is compatible with acids, weak alkalis, alcohols, gamma radiation and ultraviolet radiation. This product is not compatible with strong alkalis, organic solvents, fuels,

aromatic hydrocarbons, chlorinated hydrocarbons, esters and keytones.

WARNING! ç

All electrical power to the controller and controlled circuits must be disconnected before

removing the controller from the front panel or disconnecting other wiring. Failure to follow

these instructions may cause an electrical shock and/or sparks that could cause an explosion

in class 1, div. 2 hazardous locations.

Default Home Page Parameters

Watlow's patented user-defined menu system improves operational efficiency. The userdefined Home Page provides you with a shortcut to monitor or change the parameter values

that you use most often. The default Home Page is shown on the following page. When a parameter normally located in the Setup Page or Operations Page is placed in the Home Page,

it is accessible through both. If you change a parameter in the Home Page, it is automatically

changed in its original page. If you change a parameter in its original page it is automatically

changed in the Home Page.

Use the Advance Key ‰ to step through the other parameters. When not in pairs, the parameter prompt will appear in the lower display, and the parameter value will appear in the

upper display. You can use the Up ¿ and Down ¯ keys to change the value of writable parameters, just as you would in any other menu.

Note:

If a writable value is placed on the upper display and is paired with another read only

parameter on the lower display, the arrow keys affect the setting of the upper display. If

two writable parameters are paired, the arrow keys affect the lower display.

• The Attention attn parameter appears only if there is an active message. An example of

an active message could be a Input Error Er.i1, or it could be for information only like

Autotune tUn1 taking place.

• If Control Mode is set to Auto, the Process Value is in the upper display and the Set Point

(read-write) is in the lower display.

• If a profile is running, the process value is in the upper display and the Target Set Point

(read only) is in the lower display. If Control Mode is set to Manual, the Process Value is in

the upper display and Manual Power (read-write) is in the lower display.

• If Control Mode is set to Off, the Process Value is in the upper display and off (read only)

is in the lower display.

• If a sensor failure has occurred, dashes ---- will be displayed in the upper display and

the Manual Power (read-write) is in the lower display