WATLOWEZ-ZONE® PMUser’s GuidePID Controller Models

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

This EZ-ZONE® PM User’s Guide is copyrighted by Watlow Electric, Inc., © August 2016 with

all rights reserved.

EZ-ZONE PM is covered by U.S. Patent Numbers: 6005577; D553095; D553096; D553097;

D560175; D55766; and OTHER PATENTS PENDING

Chapter 1: Overview 1

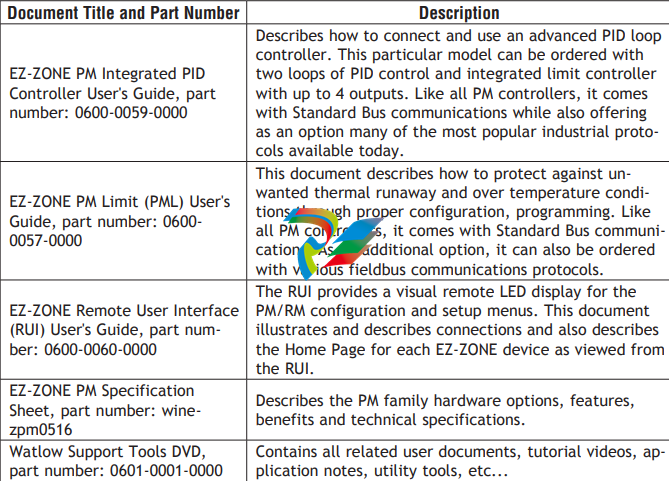

Available EZ-ZONE PM Literature and Resources

The DVD described above ships with the product and as stated contains all of the literature

above as well as much more. If the DVD is not available one can be acquired by contacting

Watlow Customer Service at 1-507-454-5300.

As an alternative to the DVD, all of the user documentation described above can also be

found on the Watlow website. Click on the following link to find your document of choice:

http://www.watlow.com/literature/index.cfm. Once there, simply type in the desired part

number (or name) into the search box and download free copies. Printed versions of all user

documents can also be purchased here as well.

Your Comments are Appreciated

In an effort to continually improve our technical literature and ensure that we are providing

information that is useful to you, we would very much appreciate your comments and suggestions. Please send any comments you may have to the following e-mail address:

TechlitComments@watlow.com

Introduction

The EZ-ZONE® PM takes the pain out of solving your thermal loop requirements. Watlow’s

EZ-ZONE PM controllers offer options to reduce system complexity and the cost of control

loop ownership. You can order the EZ-ZONE PM as a PID controller or an over-under limit

controller, or you can combine both functions in the PM Integrated Controller. You now have

the option to integrate a high-amperage power controller output, an over-under limit controller and a high-performance PID controller all in space saving, panel-mount packages. You

can also select from a number of industrial serial communications options to help you manage system performance.

Standard Features and Benefits

Advanced PID Control Algorithm

• TRU-TUNE+® Adaptive tune provides tighter control for demanding applications.

• Auto Tune for fast, efficient start ups

High-amperage Power Control Output

• Drives 15 amp resistive loads directly

• Reduces component count

• Saves panel space and simplifies wiring

• Reduces the cost of ownership

EZ-ZONE configuration communications and software

• Saves time and improves the reliability of controller set up

Parameter Save & Restore Memory

• Reduces service calls and down time

Agency approvals: UL Listed, CSA, CE, RoHS, W.E.E.E. FM

• Assures prompt product acceptance

• Reduces end product documentation costs

• Semi F47-0200

P3T Armor Sealing System

• NEMA 4X and IP65 offers water and dust resistance, can be cleaned and washed down (indoor use only)

• Backed up by UL 50 independent certification to NEMA 4X specification

Three-year warranty

• Demonstrates Watlow’s reliability and product support

Touch-safe Package

• IP2X increased safety for installers and operators

Removable cage clamp wiring connectors

• Reliable wiring, reduced service calls

• Simplified installation

EZ-Key/s

• Programmable EZ-Key enables simple one-touch operation of repetitive user activities

Programmable Menu System

• Reduces set up time and increases operator efficiency

Full-featured Alarms

• Improves operator recognition of system faults

• Control of auxiliary devices

Heat-Cool Operation

• Provides application flexibility with accurate temperature and process control

Profile Capability

• Pre-programmed process control

• Ramp and soak programming with four files and 40 total steps

Getting Started Quickly

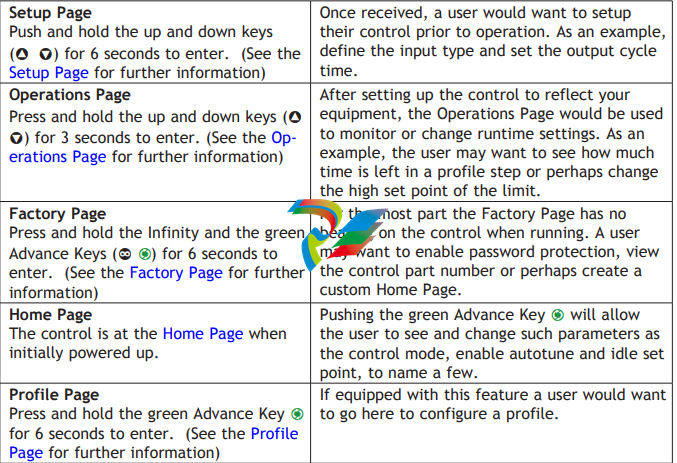

The PM control has a page and menu structure that is listed below along with a brief description of its purpose.

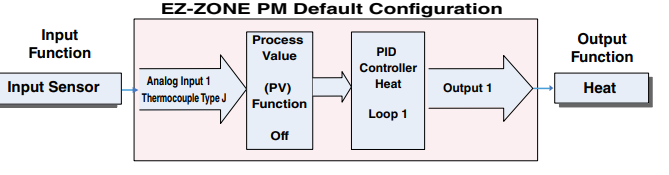

The default PM loop configuration from the factory is shown below:

• Analog Input functions set to thermocouple, type J

• Heat algorithm set for PID, Cool set to off

• Output 1 set to Heat

• Control mode set to Auto

• Set point set to 75 °F

If you are using the input type shown above, simply connect your input and output devices

to the control. Power up the control and push the up arrow ¿ on the face of the control to

change the set point from the default value of 75°F to the desired value. As the Set Point

increases above the Process Value, output 1 will come on and it will now begin driving your

output device. The PV function as shown in the graphic below is only available with PM4/8/9

models.

Note:

The output cycle time will have a bearing on the life of mechanical relay outputs and can

be different based on the type of output ordered. The output cycle time can be changed

in the Setup Page under the Output Menu.

A Conceptual View of the PM

The flexibility of the PM’s software and hardware allows a large range of configurations. Acquiring a better understanding of the controller’s overall functionality and capabilities while

at the same time planning out how the controller can be used will deliver maximum effectiveness in your application.