WATLOWEZ-ZONE® PMUser’s GuidePID Controller Models

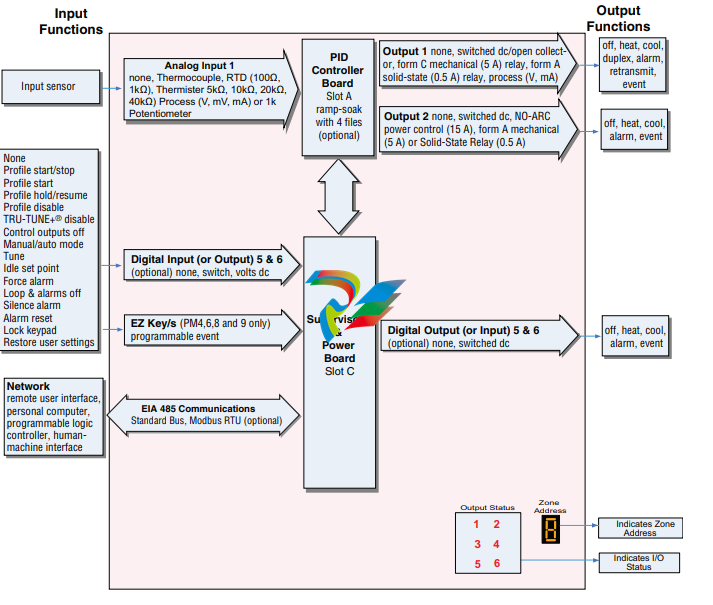

It is useful to think of the controller in three parts: inputs; procedures; and outputs. Information flows from an input to a procedure to an output when the controller is properly

configured. A single PM controller can carry out several procedures at the same time, for

instance closed-loop control, monitoring for several different alarm situations and operating

switched devices, such as lights and motors. Each process needs to be thought out carefully

and the controller’s inputs, procedures and outputs set up properly.

Inputs

The inputs provide the information that any given programmed procedure can act upon. In a

simple form, this information may come from an operator pushing a button or from a sensor

monitoring the temperature of a part being heated or cooled.

Each analog input typically uses a thermocouple or RTD to read the process temperature. It

can also read volts, current or resistance, allowing it to use various devices to read a wide

array of values.

A PM with digital input/output (DIO) hardware includes two sets of terminals where each of

which can be used as either an input or an output. Each pair of terminals must be configured

to function as either an input or output with the direction parameter in the Digital Input/

Output Menu (Setup Page). Each digital input reads whether a device is active or inactive.

The Function or EZ Key/s (PM4/6/8/9 only) on the front panel of the PM also operates as a

digital input by toggling the function assigned to it in the Digital Input Function parameter in

the Function Key Menu (Setup Page).

Internal Functions

The controller will use input signals to calculate a value and then perform an operation. A

sample of some functions may be as simple as:

• Compare an input value to the set point and calculate the optimal power for a heater

• Detect a failure of the primary sensing device and trip a contactor to remove power from

the heating element

• Reading a digital input to set a state to true or false

• Evaluate an incoming temperature to determine an alarm state (on or off)

To set up a function, it’s important to define the source, or instance, to use. For example, if

the control is equipped with DIO they can be configured to respond to an alarm. If configured

as such, the digital output must be tied to the desired alarm instance (1 to 4). Using this as

an example, the Function for the digital output would be defined as an Alarm where the Instance would be selected as 1, 2, 3, or 4 corresponding to the alarm instance that will drive

the output.

Keep in mind that a function is a user-programmed internal process that does not execute

any action outside of the controller. To have any effect outside of the controller, an output

must be configured to respond to a function..

Outputs

Outputs can perform various functions or actions in response to information provided by a

function such as, removal of the control voltage to a contactor; operating a heater, turning a

light on or off, unlocking a door, etc...

Assign a Function to any available output on the Setup Page within the Output Menu or Digital Input/Output Menu. Then select which instance of that function will drive the selected

output. For example, you might assign an output to respond to alarm 4 (instance 4).

You can assign more than one output to respond to a single instance of a function. For example, alarm 2 could be used to trigger a light connected to output 1 and a siren connected

to digital output 5.

Input Events and Output Events

Input and output events are internal states that are used exclusively by profiles. The source

of an event input can come from a real-world digital input or an output from another function. Likewise, event outputs may control a physical output such as an output function block

or be used as an input to another function.

What is a Profile

A profile is a set of instructions consisting of a sequence of steps. When a profile runs, the

controller automatically executes its steps in sequence. The step type determines what action the controller performs. Steps can change temperatures and other process values gradually over time, maintain the temperatures and process values for specific periods, or repeat

a sequence of steps numerous times. At each step the profile can activate or deactivate

outputs that control other equipment. Also a step can have the controller wait for specific

conditions before proceeding such as, waiting for a switch closure and/or a specific process

value to be detected by a sensor.

EZ-ZONE® PM PID Model System Diagram

Universal Sensor Input, Configuration Communications,

Red/Green 7-Segment Display

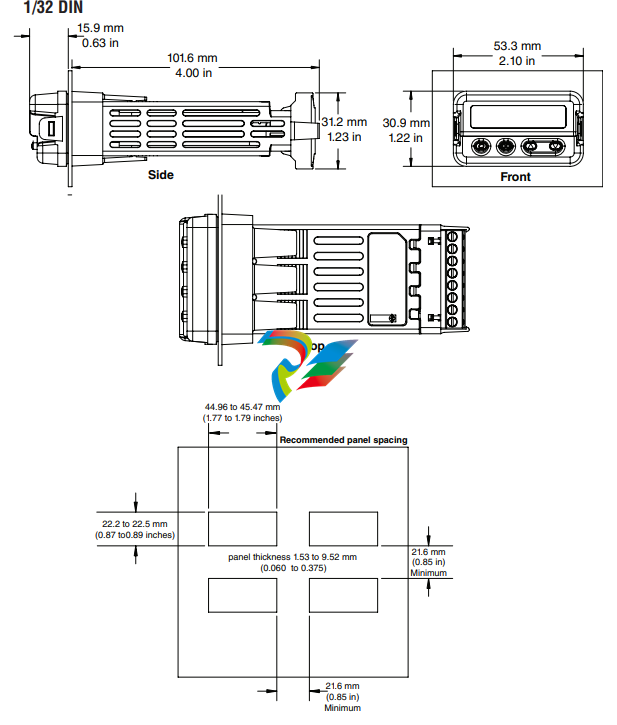

Chapter 2: Install and Wire

Installation

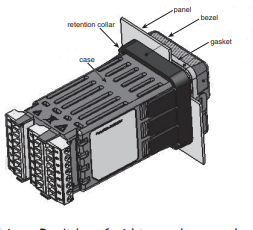

1. Make the panel cutout using the mounting template dimensions in this chapter. Insert the

case assembly into the panel cutout.

2. While pressing the case assembly firmly

against the panel, slide the mounting collar

over the back of the controller.

Note:

If the installation does not require a NEMA 4X