Summary of ABBREF615 Feeder Protection and Control Relay Product Guide

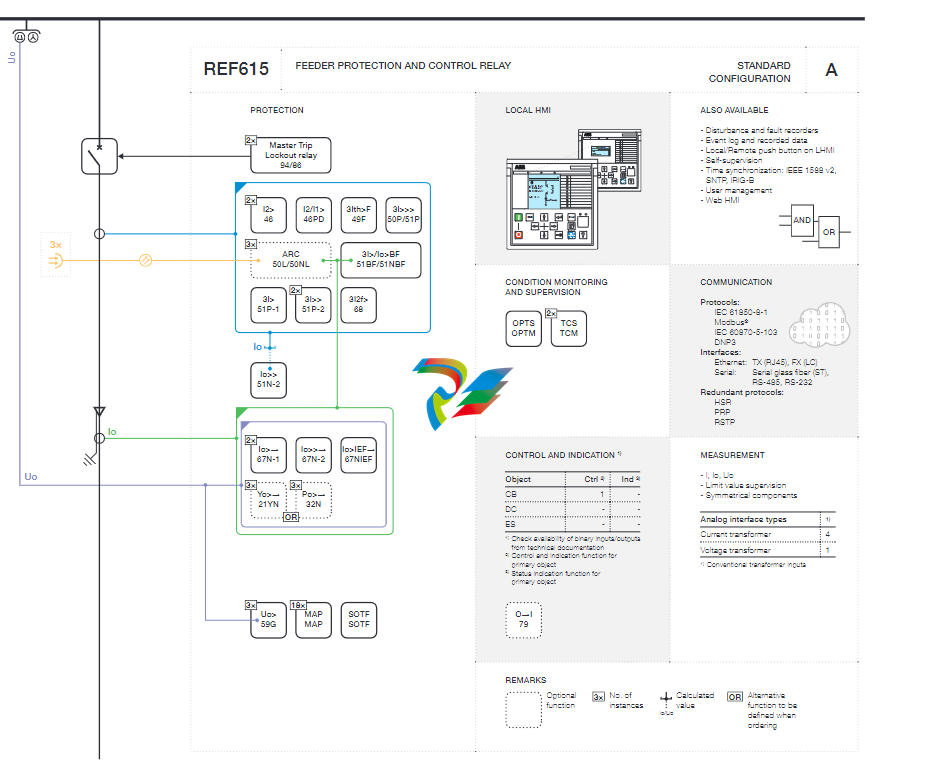

# Summary of REF615 Feeder Protection and Control Relay Product Guide (Based on ABB Relion® 615 Series, Product Version 5.0 FP1) ## I. Product Overview REF615 is a dedicated feeder protection and control relay in ABB's Relion® 615 series, designed for **protection, control, measurement, and supervision** of overhead lines and cable feeders in utility substations and industrial power systems. Its core features include: - **Application Scenarios**: Covers radial, looped, and meshed distribution networks (including distributed generation), supporting isolated neutral, resistance-earthed, compensated, and solidly earthed networks. - **Design Advantages**: Adopts a compact and withdrawable unit design, fully supports the IEC 61850 standard for communication and interoperability (including Edition 2), and can serve as primary protection or redundant backup protection. - **Core Functions**: Integrates protection, control, measurement, condition monitoring, and fault recording, with flexible configuration to adapt to diverse application requirements. ## II. Standard Configurations and Flexibility REF615 offers **12 standard configurations (A-N)**, each optimized for specific application scenarios, with key differences in protection functions, measurement ranges, and hardware interfaces. Core configuration features are as follows: | Configuration Type | Typical Application Scenarios | Key Function Highlights | |--------------------|-------------------------------|-------------------------| | A/B/C/D | Basic overcurrent and earth-fault protection (with directional/non-directional options) | Supports transient/intermittent earth-fault protection; Configurations B/D include circuit-breaker condition monitoring (RTD option). | | E/F/H/J | Industrial systems with voltage/frequency protection, supporting distributed generation grid connection | Configuration F/J adds directional overvoltage/undervoltage protection; J/K/L/N offer optional power quality monitoring (harmonics, voltage unbalance). | | G/L | Compact switchgear (e.g., ABB UniGear Digital) with combi-sensor inputs | Supports IEC 61850-9-2 LE process bus; Sensors feature no saturation and low energy consumption, suitable for space-constrained scenarios. | | K/N | High-impedance restricted earth-fault protection, busbar differential protection (most comprehensive functions) | Configuration N supports high-impedance differential protection and multifrequency admittance-based earth-fault protection, adapting to complex network topologies. | All configurations can be customized via the **PCM600 tool** with logic (e.g., timers, flip-flops) and support signal matrix and graphical application configuration to meet user-specific needs. ## III. Core Protection Functions REF615 integrates comprehensive protection functions covering various grid fault scenarios: 1. **Overcurrent Protection**: Directional/non-directional overcurrent protection (low/high/instantaneous stages) supporting ANSI/IEC inverse time curves. 2. **Earth-Fault Protection**: - Basic functions: Directional/non-directional earth-fault protection adapting to different earthing networks. - Advanced functions: Optional admittance-based, harmonics-based, and wattmetric-based earth-fault protection; Multifrequency admittance protection (in L/N configurations) for high-impedance earthed networks. 3. **Auxiliary Protection**: - Arc protection: Rapid arc fault detection via optical sensors to reduce equipment damage and personnel risks. - Frequency protection: Over/under frequency and frequency rate-of-change protection (in H/J/K/L/N configurations). - Thermal overload protection: Three-phase thermal protection for feeders, cables, and distribution transformers. - Others: Negative-sequence overcurrent protection, phase discontinuity protection, overvoltage/undervoltage protection, etc. ## IV. Applications and Integration 1. **Applicable Networks**: Adapts to isolated neutral, resistance-earthed, compensated, and solidly earthed networks; supports radial, looped, meshed networks, and distributed generation integration. 2. **Typical Applications**: - Primary and backup protection for overhead line/cable feeders. - Interconnection of industrial self-owned power plants and distribution networks (safe grid connection via synchrocheck function). - Compact switchgear scenarios (G/L configurations using combi-sensors to reduce wiring). 3. **ABB Ecosystem Integration**: - Integrates with the **COM600S Substation Management Unit** for station-level data aggregation, Web HMI monitoring, and fault analysis. - Supports IEC 61850 GOOSE horizontal communication and process bus sampled values (IEC 61850-9-2 LE), replacing traditional hardwiring. - Compatible with control systems like MicroSCADA Pro and System 800xA, enabling remote monitoring and data management. ## V. Control and Measurement 1. **Control Functions**: - Supports local/remote control of circuit breakers, disconnectors, and earthing switches via HMI or communication interfaces. - Integrates interlocking logic configuration and synchrocheck function (ensuring voltage/frequency/phase matching during grid connection). 2. **Measurement and Monitoring**: - Basic measurements: Three-phase current (I), voltage (U), residual current (Io), residual voltage (Uo), power (P/Q), energy, frequency (f), etc. - Advanced functions: Symmetrical component calculation, load profile recording (historical data stored periodically), condition monitoring (circuit breaker spring charging time, SF6 pressure, etc.). 3. **Power Quality**: Monitors voltage variation, voltage unbalance, current total demand distortion (TDD), and voltage total harmonic distortion (THD). ## VI. Communication and Data Management 1. **Communication Protocols**: Supports IEC 61850 Edition 2 (including GOOSE and sampled value transmission), Modbus, DNP3, IEC 60870-5-103; Profibus DPV1 is supported via SPA-ZC 302. 2. **Redundancy and Synchronization**: - Network redundancy: HSR, PRP protocols, or RSTP self-healing rings ensure communication reliability. - Time synchronization: Supports IEEE 1588 v2 (4µs accuracy), SNTP, and IRIG-B to meet process bus timestamp requirements. 3. **Data Recording**: - Disturbance recorder: Up to 12 analog and 64 binary channels with configurable triggering. - Event log: Stores 1024 time-stamped events in non-volatile memory. - Fault records: 128 latest fault data entries, including key parameters like current, voltage, and angle. ## VII. Technical Specifications and Safety 1. **Hardware Parameters**: - Dimensions: 177mm (width) × 177mm (height, 4U) × 201mm (depth); Weight: 4.1kg (with plug-in unit). - Power supply: AC 100-240V or DC 24-250V, maximum power consumption <18W. - Inputs/outputs: 3-phase current inputs, residual current/voltage inputs (varies by configuration); expandable binary I/Os, with high-speed outputs (HSO) to reduce operation time. 2. **EMC and Safety**: Complies with IEC 61000-4 series tests for strong anti-interference capability; supports four-level role-based access control (Viewer/Operator/Engineer/Administrator) and communication encryption (TLS) for cybersecurity. ## VIII. Conclusion As a core product in the Relion® 615 series, REF615 features **high flexibility, comprehensive protection functions, and advanced communication capabilities**, adapting to feeder protection needs from simple distribution networks to complex industrial systems. Its support for the IEC 61850 standard and diverse configurations enables seamless integration into ABB's substation automation ecosystem, providing comprehensive保障 for the safe and reliable operation of power systems.