Summary of ABB EL3000 Series Continuous Gas Analyzers

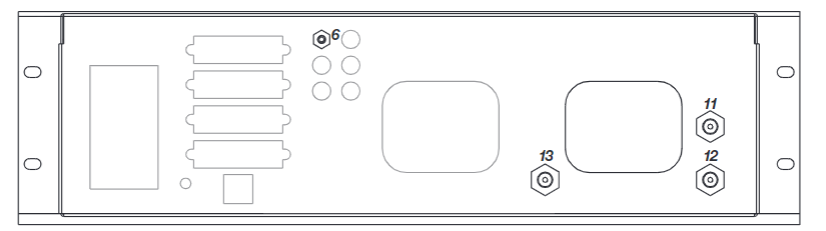

# Summary of ABB EL3000 Series Continuous Gas Analyzers ## I. Product Overview The EL3000 series is a range of continuous gas analyzers launched by ABB, designed to provide high-precision and user-friendly gas composition measurement solutions for process monitoring and emission monitoring. The series includes two models: **EL3020** (19-inch rack mounting, protection class IP20/IP40) and **EL3040** (wall-mounting, protection class IP65). It supports multiple measurement technologies, enabling simultaneous detection of up to 5 gas components, and is suitable for flammable gas measurement (specific versions) and hazardous area applications for non-flammable gases (explosion-proof versions). Core advantages include: automatic calibration (with pump and solenoid valve control), simplified calibration (no need for test gas cylinders, achievable via air or integral calibration cells), self-monitoring maintenance reminders, rich communication interfaces (Ethernet, Modbus, PROFIBUS), and application-oriented design (e.g., optional integrated pneumatics module). ## II. Core Measurement Technologies and Modules The EL3000 series adopts various measurement technologies to cover the detection needs of different gas components. Key modules and their characteristics are as follows: | Module Name | Measurement Principle | Applicable Gas Components | Core Parameters (Smallest/Largest Measurement Range) | Stability (Based on Smallest Range) | |---------------------|--------------------------------------|------------------------------------------|----------------------------------------------------------------------------------------------------------------------|------------------------------------------------------| | Uras26 | Non-dispersive infrared absorption | CO, CO₂, NO, SO₂, N₂O, CH₄, etc. | CO: 0–100 ppm / 0–100 vol.%; NO: 0–150 ppm / 0–750 ppm; SO₂: 0–100 ppm / 0–30 vol.% | Zero drift ≤1% of span/week; Sensitivity drift ≤1% of measured value/week | | Limas23 | UV resonance absorption/Non-dispersive UV absorption | NO, NO₂, SO₂ | NO: 0–50 ppm / 0–5000 ppm; SO₂: 0–100 ppm / 0–5 vol.% | Zero drift ≤3 ppm/week (for ranges ≤100 ppm); T90 ≤3 sec | | Magnos206/28 | Paramagnetic behavior of oxygen | O₂ | 0–2 vol.% / 0–100 vol.% (supports suppressed zero ranges, smallest span 2 vol.%) | Zero drift ≤3% of span/week; Repeatability ≤50 ppm O₂ | | Magnos27 | Thermomagnetic effect | O₂ in flue gas or nitrogen | 0–10 vol.% / 0–100 vol.% | Zero drift ≤1% of span/week; T90 = 10–22 sec | | ZO23 | Potentiometric measurement (zirconium dioxide cell) | O₂ in pure gases (N₂, CO₂, Ar) | 0–1 ppm / 0–250,000 ppm | Zero drift ≤1% of range/week; Detection limit ≤50 ppb O₂ | | Caldos27 | Difference in thermal conductivity | Binary gas mixtures (e.g., O₂ in Ar) | Varies by gas combination, e.g., O₂ in Ar: 0–10 vol.% / 90–100 vol.% | Linearity deviation ≤2% of span; T90 ≤2 sec | | Fidas24 | Flame ionization detection | Total hydrocarbons (THC) | 0–5 mg C/m³ / 0–5000 mg C/m³ (or 0–10 ppm C1 / 0–10000 ppm C1) | Zero drift ≤0.5 mg C/m³/week; Detection limit ≤20 µg C/m³ | | Electrochemical oxygen sensor | Electrochemical principle | O₂ | 0–5 vol.% / 0–25 vol.% | Sensitivity drift ≤1% of range/week; T90 ≤30 sec | ## III. Calibration and Operation 1. **Calibration Functions** - Supports automatic, manual, or Modbus externally controlled calibration. Automatic calibration can be triggered cyclically, via external signals, or manually. - Calibration methods: Uses integral calibration cells (verification recommended annually) or test gases. Solenoid valves can be configured to switch between 5 test gases, zero gas, and sample gas. 2. **Operation and Configuration** - Daily functions are operated directly on the analyzer; low-frequency functions (e.g., startup configuration) need to be configured offline using the "EasyLine Configuration Tool (ECT)" software before loading. - Display and operation: Equipped with a backlit graphics display (240×160 pixels), supporting 5-key menu operation, capable of displaying up to 5 measured values and status information simultaneously. ## IV. Interfaces and Communication - **Electrical Interfaces**: - Standard Ethernet (10/100BASE-T) supporting Modbus TCP/IP, ECT configuration, and QAL3 data transmission. - Optional modules: PROFIBUS (RS485/MBP), Modbus (RS485/RS232), digital I/O (4 inputs, 4 outputs), analog outputs (2-channel/4-channel, 4–20 mA). - **Modbus RTU Module**: Supports addresses 1–32, baud rates 4800–38400 bps, with function codes including 03 (Read Holding Registers) and 06 (Write Single Register), enabling remote status reading and control switching. ## V. Installation and Environmental Requirements 1. **Installation Conditions** - Ambient temperature: Operation +5~+45°C (for some modules +5~+40°C); Storage/transport -25~+65°C. - Sample gas conditions: Dew point must be at least 5°C lower than the temperature of the sample gas path (otherwise, a cooler or condensate trap is required); Flow rate 20–100 l/h (30–90 l/h for some modules); Absolute pressure 800–1250 hPa (customization required for high altitudes). - Corrosive gases: Components such as Cl₂ and HCl require preprocessing (cooling or absorption); Flammable gases require stainless steel pipeline versions, with concentrations not exceeding 100 ppm (ZO23) or 15 vol.% CH₄ equivalent (Fidas24). 2. **Installation Methods** - EL3020: 19-inch rack mounting (3U height, 4U with Magnos27); EL3040: Wall-mounting, with purge flow 10–20 l/h if purging is required. ## VI. Safety and Certifications - **Explosion-Proof Version**: EL3040 optionally holds II 3G Ex nA nC IIC T4 Gc explosion-proof certification, suitable for hazardous areas with non-flammable gases. - **Compliance**: Conforms to EN 15267 (emission monitoring performance), EN 14181 (QAL3 monitoring, optional), CE directives (Low Voltage, EMC, ATEX), CSA certification (North America), and GOST TR CU certification (Eurasian Customs Union). - **Functional Safety**: Magnos206 complies with EN 61508 standard, suitable for functional safety scenarios. ## VII. Special Functions and Options - **QAL3 Monitoring**: Optional function that automatically acquires, verifies, and records zero/reference point drift and precision, supports CUSUM and Shewhart control charts, stores data for 1 year, and is accessible via web browser. - **Integral Gas Feed**: EL3020 optionally features an integral gas feed module with solenoid valves, pumps, filters, etc., simplifying sample gas handling. - **Measurement Range Switching**: Supports manual, automatic (threshold-triggered), or external control switching, with switching status feedback via digital outputs. Document version: DS/EL3000-EN Rev. A. Technical parameters are subject to change. For more information, refer to official ABB materials.