ABB OTM_C_Summary of 21D Automatic Transfer Switch

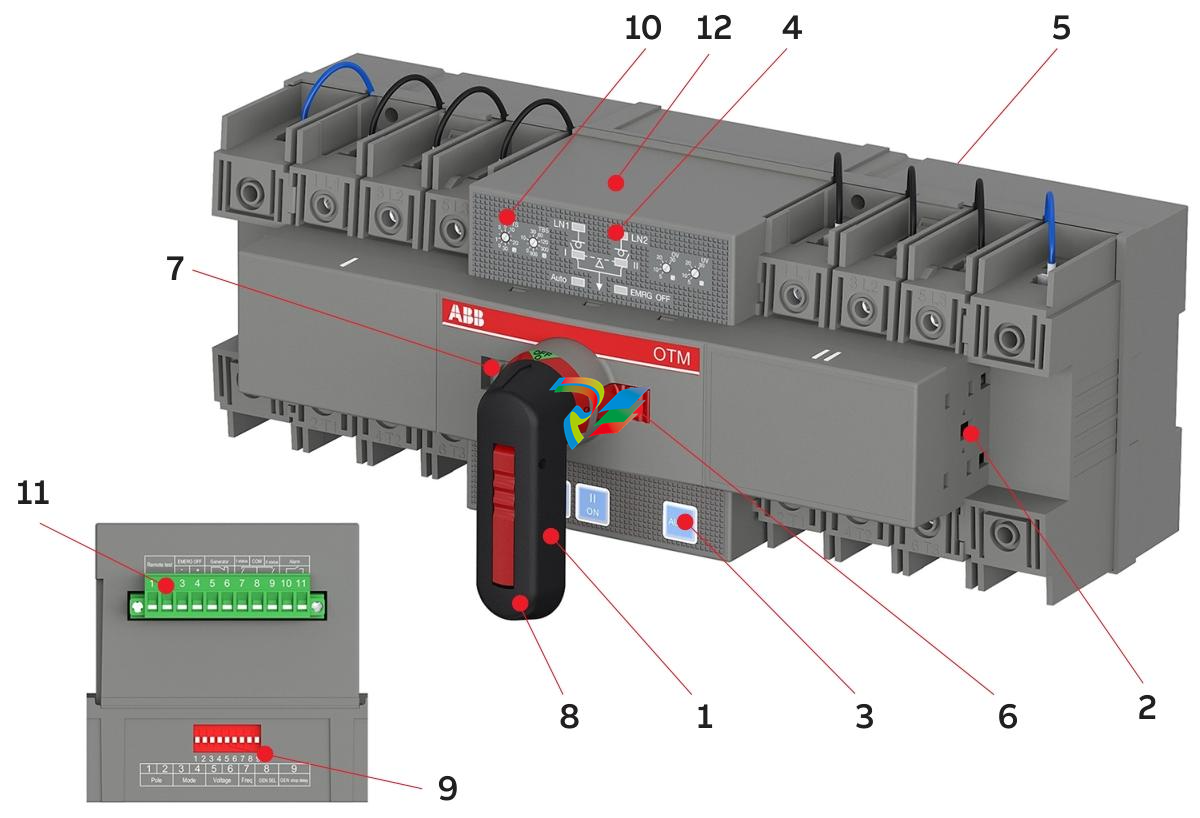

# Summary of ABB OTM_C_21D Automatic Transfer Switch ## I. Product Overview The OTM_C_21D is an automatic transfer switch launched by ABB, suitable for power source switching scenarios in three-phase or single-phase electrical networks. Its core functions include monitoring power abnormalities (no voltage, phase loss, overvoltage, undervoltage), enabling automatic/manual power switching, supporting generator start/stop control and remote testing, and achieving communication capabilities through an optional Modbus RTU module . The standard package includes an automatic transfer switch, an operating handle, a handle storage clip, a terminal plug, and an installation kit. It supports three operating modes: **Line 1 priority mode (default)**, no line priority mode, and manual return mode, meeting the power supply reliability requirements of different scenarios . ## II. Core Functions and Operating Modes ### 1. Switching Logic - **Line 1 Priority Mode**: Under normal conditions, Line 1 (primary power supply) is used. When an anomaly occurs on Line 1, it switches to Line 2 (backup power supply) after a transfer delay (Ts). When Line 1 recovers, it switches back to Line 1 after a return delay (TBs), and triggers a generator stop delay (Gs) simultaneously . - **No Line Priority Mode**: There is no priority between primary and backup power supplies. When an anomaly occurs on either line, it switches to the other line. It does not automatically return after the line recovers and only switches when the current line has an anomaly . - **Manual Return Mode**: It automatically switches to Line 2 when Line 1 is abnormal, but manual operation is required to return after Line 1 recovers, suitable for scenarios requiring manual confirmation . ### 2. Control Methods - **Manual Operation**: Inserting the handle automatically enters manual mode, disabling automatic switching. The switch can be toggled to positions I (Line 1), O (open), and II (Line 2) via the handle . - **Automatic Operation**: Pull out the handle and press the "AUTO" button; the LED lights up to indicate entry into automatic mode, with switching performed automatically according to preset logic . - **Testing Functions**: - **Local Test**: Manually trigger a switching cycle via the panel "I/O/II" buttons in automatic mode . - **Remote Test**: Short-circuit the remote test signal (≥100ms), and the switch simulates the switching process before returning to the initial position. The test can be canceled by pressing the "AUTO" button . ## III. Interfaces and Parameter Settings ### 1. Hardware Interfaces - **Buttons and Indicators**: Includes buttons "I (Line 1 closing)", "O (opening)", "II (Line 2 closing)", and "AUTO (automatic mode switching)"; LED indicators show power status (LN1/LN2), switch position (I/II), automatic mode (AUTO), and emergency stop (EMRG OFF) . - **Terminals**: There are 11 terminals in total, supporting remote test signal input, 24V DC emergency stop signal input, generator start/stop signal output, switch status feedback, and alarm signal output (dry contact, requiring external power supply) . - **DIP Switches and Knobs**: - 9-bit DIP switch: Sets the number of poles (2P/3P/4P), operating mode, rated voltage (220/380V, etc.), frequency (50/60Hz), generator enable, and stop delay (30s/240s) . - Rotary knobs: Adjust transfer delay (Ts: 0~30s), return delay (TBs: 0~900s), overvoltage threshold (OV: 5%~30%), and undervoltage threshold (UV: 5%~30%) . ### 2. Communication Function (Optional Modbus RTU Module) - **Parameters**: Address 1~32 (default 1), baud rate 4800~38400bps (default 9600bps), parity Even (default), stop bit 1 (default) . - **Function Codes**: Supports 03 (Read Holding Registers), 04 (Read Input Registers), 06 (Write Single Register), etc., enabling reading of switch status, voltage, alarm information, remote control of switching, and parameter configuration . - **Security Tips**: Firewalls, authentication measures, etc., need to be deployed to protect network communication; the Modbus protocol does not provide data encryption or authentication . ## IV. Technical Parameters and Installation ### 1. Technical Parameters | Item | Specification | |---------------------|-----------------------------------------------| | Rated Voltage | Single-phase 220~240V AC; Three-phase 380/400/415V AC | | Frequency | 50/60Hz | | Operating Voltage Range | 0.7~1.3 Ue | | Measurement Accuracy | ±3% | | Transfer Time | Total transfer time ≤2.5s, opening time 0.6~0.7s | | Output Relay Capacity | 3A AC1, 250V AC/24V DC | | Protection Class | IP20 (front panel) | | Operating Temperature | -25~55°C | | Altitude | Maximum 2000m | ### 2. Installation Requirements - **Installation Methods**: Supports screw fixing (M4 screws, torque 2Nm) or DIN rail mounting (requires locking clips to prevent falling off) . - **Dimensions**: 3-pole 233mm×130mm×95mm, 4-pole 286mm×130mm×95mm (length×width×height) . - **Wiring**: Terminals support a maximum of 70mm² wires, with up to 2 wires per terminal. Phase wires and neutral wires must be distinguished to avoid incorrect connection leading to faults . ## V. Maintenance and Troubleshooting ### 1. Maintenance Recommendations - Perform a switching test every 3 months to confirm that automatic/manual functions are normal . - Regularly check terminal connections, indicator lights, and mechanical component status, and clean dust . ### 2. Common Troubleshooting | Fault Phenomenon | Possible Cause | Solution | |-----------------------------------|-----------------------------------|-------------------------------------------| | LED not on despite normal power supply | Control unit not powered | Check and connect the power cord | | "AUTO" light not on or unresponsive | Handle not pulled out or electronic lock not released | Pull out the handle or remove the padlock, press "AUTO" to reset | | No automatic switching when power is abnormal | Not in automatic mode or dual power supplies faulty simultaneously | Confirm it is in automatic mode and troubleshoot power faults | | Emergency stop (EMRG OFF) function invalid | Signal not 24V DC or duration less than 1s | Connect the correct signal and extend the trigger time | | "AUTO" light blinking | Invalid DIP switch settings or generator enabled in no-priority mode | Correct DIP switch configuration and turn off the generator in no-priority mode | | Modbus unable to control or modify parameters | In local monitoring mode | Switch to remote control mode (set register 33 to 1) | ## VI. Optional Accessories and Safety Tips - **Optional Accessories**: Bridging bars (OMZC03/04), terminal shrouds (OTS125T), auxiliary contact blocks (OA7G10, etc.), Modbus RTU communication module . - **Safety Tips**: - Only qualified electricians are allowed to install and maintain; disconnect power and verify no voltage before operation . - The emergency stop signal must be connected to 24V DC; only manual operation is supported after triggering, and press "AUTO" to exit after canceling the signal . - Locking function: Supports padlocking to lock electrical operation (any position) or manual operation (only O position) to prevent misoperation . Document version: 34OTM_C_21D rev. E (November 2021). Technical parameters are subject to change. For more support, visit abb.com/lowvoltage .