rolls-royce User Manual Rolls-Royce Helicon X3 P&T Control System

Controller.)

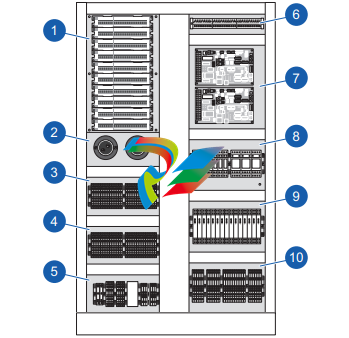

1. Rolls-Royce Marine Controller (Normal)

2. Rolls-Royce Marine Controller (Backup)

3. I/O modules

4. Power distribution

5. Network switches and terminals

6. Signal isolation amplifiers (optional)

7. Power Distribution

8. Main power supply (AC) / fuses

9. Backup power supply (DC) / fuses

3.7 I/O Cabinet

The I/O cabinet is often located in the thruster room near sensors and actuators. This

cabinet distributes signals to the different propulsion/thruster units. There is one I/O unit

per propeller/thruster.

The I/O cabinet sends signals to the actuators on the propellers/thrusters and receives

signals from the sensors. There is CAN bus communication between each I/O and

controller cabinet.

Normal Control

The output from the pitch controller is computed on the basis of the input signals from

pitch lever and the actuator position feedback.

Lever and feedback signals are scaled and checked against adjustable limits, with

corresponding alarm for exceeding the normal range. The levers have one set of

adjustments (minimum, zero and maximum) for each manoeuvre station. Multiple sets

of feedback adjustments (minimum, zero and maximum) are available for various

engine power take-outs.

In combined mode the lever signal is modified in a Combinator program, see chapter

Pitch and RPM Combinatory (combined Control).

4.1.2 Backup Control

The Backup Control system consists of closed loop control identical to the Normal

Control system. The Backup Control is a separate system, and is independent of the

Normal Control system. A system failure in the Normal Control system will

automatically switch to and engage the Backup Control.

Lever order signals and feedback are monitored and verified against adjustable alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant and

both visual and audible system failure alarm will be actuated at the manoeuvre stations.

4.1.3 Backup Control Operation

If a failure occurs on important parts of the Normal Control for the Pitch, Azimuth or

RPM Control function, the control will automatically be switched over to the Backup

Control system. A system failure audible and visible alarm will be activated on each of

the control panels.

The thruster control will continue to follow the lever in command and transfer is done

by using the common in command buttons. The command can be transferred between

all bridge position and the bridge control levers will continue to work as in normal

control.

A failure that occurs on important parts of the Backup Control for the Pitch, Azimuth or

RPM Control function will not affect the Normal Control system. If a system failure

occurs on the Backup Control an audible and visible alarm will be activated on each of

the control panels.

4.1.4 Backup Control Limitations

The Backup Control system has only interface to the control levers. The Backup Control

system does not have interface to External Control systems like Dynamic positioning

systems, Joysticks or Autopilots.

No pitch reduction or load function are included in the Backup system.

When operating using the backup system, the operator must be careful not to overload

the engine or the propeller system.

4.1.5 Local Control

If both the Remote Control system and the Backup Control should fail it is possible to

operate the propeller pitch locally from the pitch control valve.

4.1.6 Pitch Indication

The Pitch Indication system is independent of the Normal Pitch Control system by

means of separate transmitters and electronic circuits. The pitch indicators are connected

in series and are driven from the Backup Control system.

4.1.7 Pitch Order Scaling

The system may need to reduce the pitch order for different reasons. The pitch reduction

can either be activated from a digital or anlogue input signal.

To reserve engine power to heavy consumers as alternators, fire pumps, etc., it may be

necessary to reduce the available propeller output power. This is normally done by

means of a fixed propeller pitch reduction.

If the drive motor is a diesel engine the system is prepared to handle a fuel limiter

contact, from the RPM governor (i.e. high scavange air pressure). If the contact is closed

the pitch order will stop increasing to a higher value, only decrease of pitch order against

zero is possible.

For azimuth thrusters, a pitch reduction will be activated if the azimuth order is changed

faster then the thruster azimuth servo can follow.

4.2 Thruster Azimuth Control

The azimuth control function is to obtain the correct thruster azimuth position in

accordance to the control lever order. Valve controlled hydraulic motors or frequency

controlled electro motors perform the positioning of the thruster azimuth.

Detailed information regarding the hydraulic system or motor data is available in the

Thruster Instruction manual.

Note: Test point angle signals are ranged +/- 100%, representing +/- 180 degrees.

Some test points are named with degrees, displaying the angle in degrees

.png)

.png)

.png)