EMERSONMVME55006E Single-Board Computer Installation and Use

ESD

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system. Electronic components,

such as disk drives, computer boards, and memory modules can be extremely

sensitive to electrostatic discharge (ESD). After removing the component from its

protective wrapper or from the system, place the component flat on a grounded,

static-free surface (and, in the case of a board, component side up). Do not slide the

component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available at electronics stores) that is attached to an

active electrical ground. Note that a system chassis may not be grounded if it is

unplugged.

Personal Injury or Death

Dangerous voltages, capable of causing death, are present in this equipment.

Use extreme caution when handling, testing, and adjusting.

Configuring the Hardware

This section discusses certain hardware and software tasks that may need to be performed

prior to installing the board in a chassis.

To produce the desired configuration and ensure proper operation of the MVME5500, you may

need to carry out certain hardware modifications before installing the module.

Most options on the MVME5500 are software configurable. Configuration changes are made

by setting bits in control registers after the board is installed in a system.

Jumpers and switches are used to control those options that are not software configurable.

These settings are described further on in this section. If you are resetting the board jumpers

or switches from their default settings, it is important to verify that all settings are reset properly.

Configuring the Board

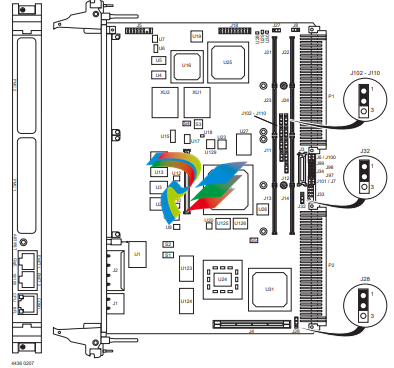

Figure 1-1 illustrates the placement of the jumpers, headers, switches, connectors, and various

other components on the MVME5500. There are several manually configurable headers and

switches on the MVME5500 and their settings are shown in Table 1-2. Each default setting is

enclosed in brackets. For pin assignments on the MVME5500, refer to Chapter 5, Connector

Pin Assignments.

Table 1-2 MVME5500 Jumper Settings

The MVME5500 is factory tested and shipped with the configuration described in the following

section.

1.6.2 Ethernet 2, PMC/SBC Mode, and P2 I/O Selection Headers (J6,

J7, J28, J32, J34, J97 – J110)

All of the headers described below are used in conjunction with each other to select various

modes of operation for 10/100BaseT Ethernet, PMC/SBC mode, and P2 I/O mode.

1.6.2.1 Ethernet

Four 3-pin planar headers (J6, J7, J100, J101) and four 2-pin planar headers (J34, J97, J98,

J99) are for 10/100/BaseT Ethernet 2 selection.

Ethernet 1 is the Gigabit Ethernet port and is front panel only.

Figure 1-1 MVME5500 Board Layout

For J6, J100, J7 and J101, install jumpers across pins 2-3 on all four headers for rear P2

Ethernet. For front-panel Ethernet, install jumpers across pins 1-2 on all four headers.

For J34, J97, J98 and J99, no jumpers are installed for front-panel Ethernet. For rear P2

Ethernet, install jumpers across pins 1-2 on all four headers when in SBC/IPMC761 mode.

1.6.2.2 PMC/SBC Mode Selection

The MVME5500 is set at the factory for PMC mode. The SBC/IPMC761 mode should only be

selected when using the IPMC761 module in conjunction with the MVME761 transition

module.The PMC mode should be selected when using PMC modules with specific user I/O in

conjunction with the corresponding transition module. PMC mode should also be selected when

using PrPMC modules.

Two 3-pin planar headers (J28, J32) control the supply of +/- 12 volts to the P2 connector; one

or both of these voltages are required by the MVME712 or MVME761 module when operating

in SBC mode. For PMC mode, jumpers are installed across pins 1-2 on both headers. For

SBC/IPMC761 mode, install jumpers across pins 2-3 on both headers. For SBC/IPMC712

mode, install a jumper across pins 2-3 for J32 and install a jumper across pins 1-2 for J28

Product Damage

When J28 is configured for SBC/IPMC mode, –12V is supplied to P2 pin A30. If there

is an incompatible board plugged into this P2 slot, damage may occur.

When J32 is configured for SBC/IPMC mode, +12V is supplied to P2 pin C7. If there is

an incompatible board plugged into this P2 slot, damage may occur.

P2 I/O Selection

Nine 3-pin planar headers (J102 –J110) are for P2 I/O selection. Jumpers are installed across

pins 1-2 on all nine headers when in PMC mode. Install jumpers across pins 2-3 on all nine

headers when in SBC/IPMC761 or SBC/IPMC712 mode to connect the extended SCSI signals

to P2

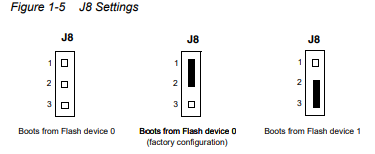

Flash Boot Bank Select Header (J8)

A 3-pin planar header selects the boot Flash bank. No jumper or a jumper installed across pins

1-2 selects Flash 0 as the boot bank. A jumper installed across pins 2-3 selects Flash 1 as the

boot bank.

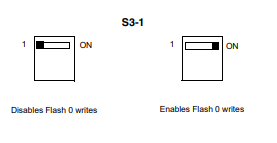

Flash 0 Programming Enable Switch (S3-1)

This switch enables/disables programming of Flash 0 as a means of protecting the contents

from being corrupted. The switch set to OFF disables all Flash 0 programming. The switch set

to ON enables the programming, this is the factory setting

Safe Start ENV Switch (S5-1)

This switch selects programmed or safe start ENV settings. When set to OFF, it indicates that

the programmed ENV settings should be used during boot. Set to ON indicates that the safe

ENV settings should be used.

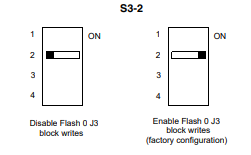

Flash 0 Block Write Protect Switch (S3-2)

This switch supports the Intel J3 Flash family write protect feature. Set to OFF, it enables the

lock-down mechanism. Blocks locked down cannot be unlocked with the unlock command. The

switch must be set to ON in order to override the lock-down function and enable blocks to be

erased or programmed through software. Refer to the Intel J3 Flash data sheet, listed in

Appendix C, Related Documentation, for further details.

SROM Initialization Enable Switch (S5-2)

This switch enables/disables the GT-64260B SROM initialization. When set to 2, it enables the

GT-64260B device initialization via I2C SROM. Set to ON disables this initialization sequence

PCI Bus 0.0 Speed Switch (S4-1)

This switch can force PCI bus 0.0 to run at 33 MHz rather than the standard method of allowing

the PMC board to control whether the bus runs at 33 MHz or 66 MHz. Set to 1, it allows the

PMC board to choose the PCI 0.0 bus speed. Set to ON forces PCI bus 0.0 to run at 33 MHz

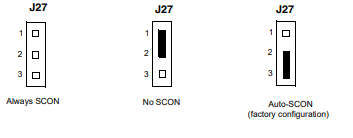

VME SCON Select Header (J27)

A 3-pin planar header allows the choice for auto/enable/disable SCON VME configuration. A

jumper installed across pins 1-2 configures for SCON disabled. A jumper installed across pins

2-3 configures for auto SCON. No jumper installed configures for SCON always enabled.

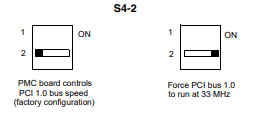

PCI Bus 1.0 Speed Switch (S4-2)

This switch can force PCI bus 1.0 to run at 33 MHz rather than the standard method of allowing

the PMC board to control whether the bus runs at 33 MHz or 66 MHz. Set to 1, it allows the

PMC board to choose the PCI 1.0 bus speed. Set to ON forces PCI bus 1.0 to run at 33 MHz

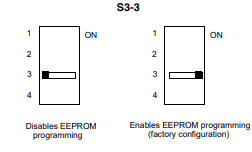

EEPROM Write Protect Switch (S3-3)

This switch enables/disables programming of the on-board EEPROMs as a means of protecting

the contents from being corrupted. Set to 1, it disables EEPROM programming by driving the

WP pin to a logic high. Set to ON to program any of the EEPROMs at addresses A0, A6, A8,

and/or AA.

Setting the PMC Vio Keying Pin

Signalling voltage (Vio) is determined by the location of the PMC Vio keying pin. Each site can

be independently configured for either +5V or +3.3V signalling. The option selected can be

determined by observing the location of the Vio keying pin.

Figure 1-13 S3-3 Settings

Disables EEPROM Enables EEPROM programming

programming (factory configuration)

Installing the RAM5500 Module

Procedure

To upgrade or install a RAM5500 module, refer to and proceed as follows:

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to the

chassis as a ground. The ESD strap must be secured to your wrist and to ground

throughout the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power off and remove

the AC cord or DC power lines from the system. Remove the chassis or system

cover(s) as necessary for access to the VME boards.

3. Carefully remove the MVME5500 from its VME card slot and lay it flat, with

connectors P1 and P2 facing you.

4. Inspect the RAM5500 module that is being installed on the MVME5500 host board

to ensure that standoffs are installed in the four mounting holes on the module.

5. With standoffs installed in the four mounting holes on the RAM5500 module, align

the standoffs and the P1 connector on the module with the four holes and the P4

connector on the MVME5500 host board and press the two connectors together

until they are firmly seated in place.

7. Reinstall the MVME5500 assembly in its proper card slot following the procedure in

the next section. Be sure the host board is well seated in the backplane connectors.

Do not damage or bend connector pins.

8. Replace the chassis or system cover(s), reconnect the system to the AC or DC

power source and turn the equipment power on.

1.8 Installing PMCs

This section discusses the installation of a PMC module onto the MVME5500 and the

installation of a primary and secondary PMCspan module onto the PMC/MVME5500 processor

module.

If you have ordered one or more of the optional RAM500 memory mezzanine boards for the

MVME5500, ensure that they are installed on the board prior to proceeding. If they have not

been installed by the factory, and you are installing them yourself, please refer to Installing the

RAM5500 Module on page 28 for installation instructions. It is recommended that the memory

mezzanine modules be installed prior to installing other board accessories, such as PMCs,

IPMCs or transition modules.

1.8.1 Mounting the PMC Module

PMC modules mount on top of the MVME5500. Perform the following steps to install a

PMCmodule on your MVME5500.

Personal Injury or Death

Dangerous voltages, capable of causing death, are present in this equipment.

Use extreme caution when handling, testing and adjusting.

Product Damage

Inserting or removing modules with power applied may result in damage to module

components.

Avoid touching areas of integrated circuitry, static discharge can damage these

Procedure

This procedure assumes that you have read the user’s manual that came with your PMCs.

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an

electrical ground. Note that the system chassis may not be grounded if it is

unplugged. The ESD strap must be secured to your wrist and to ground throughout

the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power off and remove

the AC cord or DC power lines from the system. Remove chassis or system cover(s)

as necessary for access to the VME modules.

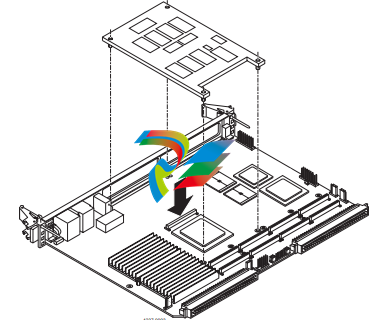

3. If the MVME5500 has already been installed in a VMEbus card slot, carefully

remove it as shown in Figure 1-17 and place it with connectors P1 and P2 facing

you. Remove the filler plate(s) from the front panel of the MVME5500.

4. Insert the appropriate number of Phillips screws (typically 4) from the bottom of the

MVME5500 into the standoffs on the PMC module and tighten the screws (refer to

Figure 1-15).

5. Align the PMC module’s mating connectors to the MVME5500’s mating connectors

and press firmly into place.

1.8.2 Primary PMCspan

To install a PMCspan26E-002 PCI expansion module on your MVME5500, perform the

following steps while referring to the figure on the next page:

Figure 1-15 Typical Placement of a PMC Module on a VME Module

Procedure

This procedure assumes that you have read the user’s manual that was furnished with your

PMCspan.

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an

electrical ground. Note that the system chassis may not be grounded if it is

unplugged. The ESD strap must be secured to your wrist and to ground throughout

the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power off and remove

the AC cord or DC power lines from the system. Remove chassis or system cover(s)

as necessary for access to the VME modules.

3. If the MVME5500 has already been installed in a VMEbus card slot, carefully

remove it as shown in Figure 1-17 and place it with connectors P1 and P2 facing

you.

4. Attach the four standoffs to the MVME5500. For each standoff:

Insert the threaded end into the standoff hole at each corner of the MVME5500 and

thread the locking nuts into the standoff tips and tighten.

5. Place the PMCspan on top of the MVME5500. Align the mounting holes in each

corner to the standoffs and align PMCspan connector P4 with MVME5100

connector J25.

Figure 1-16 PMCspan Installation on a VME Module

6. Gently press the PMCspan and MVME5500 together and verify that P4 is fully

seated in J4.

7. Insert four short screws (Phillips type) through the holes at the corners of the

PMCspan and into the standoffs on the MVME5500. Tighten screws securely.

1.8.3 Secondary PMCspan

The PMCspanx6E-010 PCI expansion module mounts on top of a PMCspanx6E-002. To install

a PMCspanx6E-010, perform the following steps while referring to the figure on the next page:

Personal Injury or Death

Dangerous voltages, capable of causing death, are present in this equipment.

Use extreme caution when handling, testing and adjusting.

Product Damage

Inserting or removing modules with power applied may result in damage to module

components.

Avoid touching areas of integrated circuitry, static discharge can damage these

circuits.

Procedure

This procedure assumes that you have read the user’s manual that was furnished with the

PMCspan, and that you have installed the selected PMC modules on your PMCspan according

to the instructions provided in the PMCspan and PMC manuals.

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an

electrical ground. Note that the system chassis may not be grounded if it is

unplugged. The ESD strap must be secured to your wrist and to ground throughout

the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power off and remove

the AC cord or DC power lines from the system. Remove chassis or system cover(s)

as necessary for access to the VME module

3. If the Primary PMC Carrier Module and MVME5500 assembly is already installed in

the VME chassis, carefully remove it as shown in Figure 1-17 and place it with

connectors P1 and P2 facing you.

4. Remove four screws (Phillips type) from the standoffs in each corner of the primary

PCI expansion module.

5. Attach the four standoffs from the PMCspanx6E-010 mounting kit to the

PMCspanx6E-002 by screwing the threaded male portion of the standoffs in the

locations where the screws were removed in the previous step.

6. Place the PMCspanx6E-010 on top of the PMCspanx6E-002. Align the mounting

holes in each corner to the standoffs and align PMCspanx6E-010 connector P3 with

PMCspanx6E-002 connector J3.

7. Gently press the two PMCspan modules together and verify that P3 is fully seated

in J3.

8. Insert the four screws (Phillips type) through the holes at the corners of

PMCspanx6E-010 and into the standoffs on the primary PMCspanx6E-002. Tighten

screws securely.

The screws have two different head diameters. Use the screws with the smaller

heads on the standoffs next to VMEbus connectors P1 and P2.

You are now ready to install the module into the VME chassis. Follow the procedure, Installing

the Board on page 33.

Installing the Board

Procedure

Use the following steps to install the MVME5500 into your computer chassis.

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an

electrical ground (refer to Unpacking Guidelines). The ESD strap must be secured

to your wrist and to ground throughout the procedure.

2. Remove any filler panel that might fill that slot.

3. Install the top and bottom edge of the MVME5500 into the guides of the chassis.

Only use injector handles for board insertion to avoid damage/deformation to the

front panel and/or PCB.

4. Ensure that the levers of the two injector/ejectors are in the outward position.

5. Slide the MVME5500 into the chassis until resistance is felt.

6. Simultaneously move the injector/ejector levers in an inward direction.

7. Verify that the MVME5500 is properly seated and secure it to the chassis using the

two screws located adjacent to the injector/ejector levers.

8. Connect the appropriate cables to the MVME5500.

1.9.1 Connection to Peripherals

When the MVME5500 is installed in a chassis, you are ready to connect peripherals and apply

power to the board.

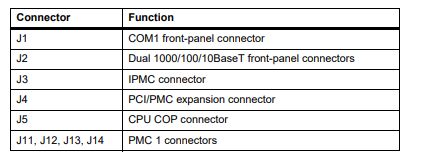

Figure 1-1 on page 20 shows the locations of the various connectors while Table 1-3 lists them

for you. Refer to Chapter 5, Connector Pin Assignments for the pin assignments of the

connectors listed below.

If a PMC module is plugged into PMC slot 1, the memory mezzanine card cannot be used

because the PMC module covers the memory mezzanine connector.

Figure 1-17 Installation into a Typical VME Chass

Completing the Installation

Verify that hardware is installed and the power/peripheral cables connected are appropriate for

your system configuration.

Replace the chassis or system cover, reconnect the system to the AC or DC power source, and

turn the equipment power on.

1.10 Startup and Operation

This section gives you information about:

z The power-up procedure

z Switches and indicators

1.11 Applying Power

After you verify that all necessary hardware preparation is complete and all connections are

made correctly, you can apply power to the system.

When you are ready to apply power to the MVME5500:

z Verify that the chassis power supply voltage setting matches the voltage present in the

country of use (if the power supply in your system is not auto-sensing)

z On powering up, the MVME5500 brings up the MotLoad prompt, MVME5500>

1.12 Switches and Indicators

The MVME5500 board provides a single push button switch that provides both Abort and Reset

(ABT/RST) functions. When the switch is depressed for less than three seconds, an abort

interrupt is generated to the processor. If the switch is held for more than three seconds, a

board hard reset is generated.

The MVME5500 has two front-panel indicators:

z BFL, software controlled. Asserted by firmware (or other software) to indicate a

configuration problem (or other failure).

z CPU, connected to a CPU bus control signal to indicate bus activity.

The following table describes these indicators:

Table 1-4 Front-Panel LED Status Indicators

Function Label Color Description

CPU Bus Activity CPU Green CPU bus is busy.

Board Fail BFL Yellow Board has a failure.

Functional Description

2.1 Overview

This chapter describes the MVME5500 on a block diagram level.

2.2 Block Diagram

Table 2-1 shows a block diagram of the overall board architecture.

Figure 2-1 Block Diagram

Features

The following table lists the features of the MVME5500.

Table 2-1 MVME5500 Features Summary

Processor

The MVME5500 supports the MPC7457 processor in the 483-pin CBGA package. The

processor consists of a processor core, an internal 256KB L2 and an internal L3 tag and

controller, which supports a backside L3 cache.

2.5 L3 Cache

The MVME5500 uses two 8Mb DDR synchronous SRAM devices for the processor’s L3 cache

data SRAM. This gives the processor a total of 2MB of L3 cache. These SRAM devices require

a 2.5V core voltage. The MVME5500 provides 1.5V as the SRAM I/O voltage. The L3 bus

operates at 200 MHz.

2.6 System Controller

The GT-64260B system controller for PowerPC architecture processors is a single chip solution

that provides the following features:

z A 64-bit interface to the CPU bus

z A 64-bit SDRAM interface

z A 32-bit generic device interface for Flash, etc.

z Two 64-bit, 66 MHz PCI bus interfaces

z Three 10/100Mb Ethernet MAC ports (two ports not used)

z A DMA engine for moving data between the buses

z An interrupt controller

z An I2C device controller

z PowerPC bus arbiter

z Counter/timers

.png)

.png)