EMERSONMVME55006E Single-Board Computer Installation and Use

ESD

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system. Electronic components,

such as disk drives, computer boards, and memory modules can be extremely

sensitive to electrostatic discharge (ESD). After removing the component from its

protective wrapper or from the system, place the component flat on a grounded,

static-free surface (and, in the case of a board, component side up). Do not slide the

component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available at electronics stores) that is attached to an

active electrical ground. Note that a system chassis may not be grounded if it is

unplugged.

Personal Injury or Death

Dangerous voltages, capable of causing death, are present in this equipment.

Use extreme caution when handling, testing, and adjusting.

Configuring the Hardware

This section discusses certain hardware and software tasks that may need to be performed

prior to installing the board in a chassis.

To produce the desired configuration and ensure proper operation of the MVME5500, you may

need to carry out certain hardware modifications before installing the module.

Most options on the MVME5500 are software configurable. Configuration changes are made

by setting bits in control registers after the board is installed in a system.

Jumpers and switches are used to control those options that are not software configurable.

These settings are described further on in this section. If you are resetting the board jumpers

or switches from their default settings, it is important to verify that all settings are reset properly.

Configuring the Board

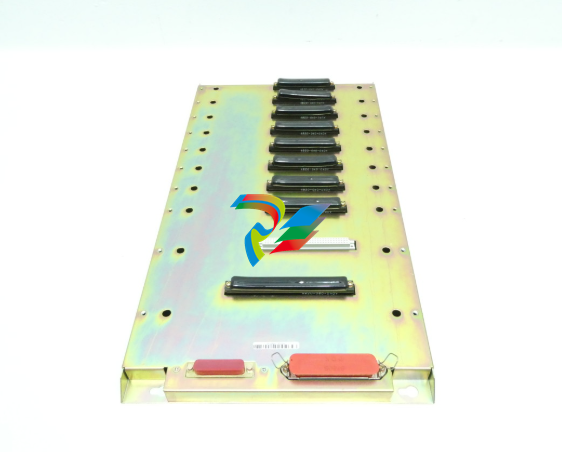

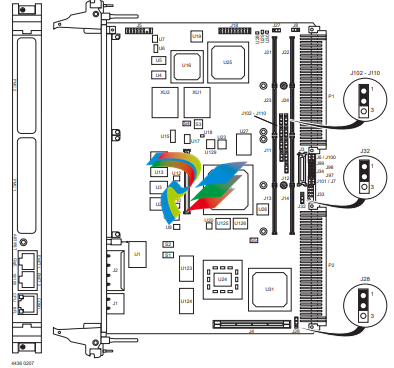

Figure 1-1 illustrates the placement of the jumpers, headers, switches, connectors, and various

other components on the MVME5500. There are several manually configurable headers and

switches on the MVME5500 and their settings are shown in Table 1-2. Each default setting is

enclosed in brackets. For pin assignments on the MVME5500, refer to Chapter 5, Connector

Pin Assignments.

Table 1-2 MVME5500 Jumper Settings

The MVME5500 is factory tested and shipped with the configuration described in the following

section.

1.6.2 Ethernet 2, PMC/SBC Mode, and P2 I/O Selection Headers (J6,

J7, J28, J32, J34, J97 – J110)

All of the headers described below are used in conjunction with each other to select various

modes of operation for 10/100BaseT Ethernet, PMC/SBC mode, and P2 I/O mode.

1.6.2.1 Ethernet

Four 3-pin planar headers (J6, J7, J100, J101) and four 2-pin planar headers (J34, J97, J98,

J99) are for 10/100/BaseT Ethernet 2 selection.

Ethernet 1 is the Gigabit Ethernet port and is front panel only.

Figure 1-1 MVME5500 Board Layout

For J6, J100, J7 and J101, install jumpers across pins 2-3 on all four headers for rear P2

Ethernet. For front-panel Ethernet, install jumpers across pins 1-2 on all four headers.

For J34, J97, J98 and J99, no jumpers are installed for front-panel Ethernet. For rear P2

Ethernet, install jumpers across pins 1-2 on all four headers when in SBC/IPMC761 mode.

1.6.2.2 PMC/SBC Mode Selection

The MVME5500 is set at the factory for PMC mode. The SBC/IPMC761 mode should only be

selected when using the IPMC761 module in conjunction with the MVME761 transition

module.The PMC mode should be selected when using PMC modules with specific user I/O in

conjunction with the corresponding transition module. PMC mode should also be selected when

using PrPMC modules.

Two 3-pin planar headers (J28, J32) control the supply of +/- 12 volts to the P2 connector; one

or both of these voltages are required by the MVME712 or MVME761 module when operating

in SBC mode. For PMC mode, jumpers are installed across pins 1-2 on both headers. For

SBC/IPMC761 mode, install jumpers across pins 2-3 on both headers. For SBC/IPMC712

mode, install a jumper across pins 2-3 for J32 and install a jumper across pins 1-2 for J28

Product Damage

When J28 is configured for SBC/IPMC mode, –12V is supplied to P2 pin A30. If there

is an incompatible board plugged into this P2 slot, damage may occur.

When J32 is configured for SBC/IPMC mode, +12V is supplied to P2 pin C7. If there is

an incompatible board plugged into this P2 slot, damage may occur.

P2 I/O Selection

Nine 3-pin planar headers (J102 –J110) are for P2 I/O selection. Jumpers are installed across

pins 1-2 on all nine headers when in PMC mode. Install jumpers across pins 2-3 on all nine

headers when in SBC/IPMC761 or SBC/IPMC712 mode to connect the extended SCSI signals

to P2

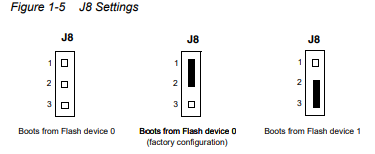

Flash Boot Bank Select Header (J8)

A 3-pin planar header selects the boot Flash bank. No jumper or a jumper installed across pins

1-2 selects Flash 0 as the boot bank. A jumper installed across pins 2-3 selects Flash 1 as the

boot bank.

Flash 0 Programming Enable Switch (S3-1)

This switch enables/disables programming of Flash 0 as a means of protecting the contents

.png)