ABB for electrical systems - CMES MService Condition Monitoring V7.7

ABB for electrical systems - CMES MService Condition Monitoring V7.7

Following cyber security-based recommendations must be considered using MService device in an in

dustrial Ethernet network environment:

• MService shall be connected to an isolated network in general. If MService is connected to a

plant network a firewall shall be considered to control access to MService web-based user inter

face.

• Insertion of a USB drive / pen-drive / stick into a USB port of MService shall be prevented at any

time except connecting an external hard-disk for data backup purpose. Inserting a faulty USB

drive (e.g. with faulty USB-HID(*) descriptor) can lead to a stop of MService functionality. In such

a case MService will not record any data from connected field devices any longer and a device

reboot is required.

To prevent an unrestricted access to the USB ports of MService USB Port Locks shall be used.

These port locks reduce the risk of data leakage, data theft and unauthorized uploads with a

software-free solution that physically blocks USB ports from unauthorized access. There’s even

an option to block multiple adjacent ports with one lock and allow continued secure use of au

thorized USB devices.

• User must log-off from MService when leaving the workplace to prevent another person using

the active login account. The log-off button must be used in this case as closing the Web

browser will not terminate the active web-session.

2 System Overview

2.1 Product Concept

The MService device implements an innovative approach to condition monitoring: The supervision of

the performance and health status of a MNS and MNS iS switchgear are made possible with a small

scale and easy-to-use embedded industrial PC.

The MService implements the whole condition monitoring concept from collecting field level real-time

data to performing assessment algorithms. Based on that, it is possible to work out a prognosis of

developing situations and prompting the operator for action. However, if the situation continues and

results in a tripping or failure, the MService offers clear diagnosis for fast problem resolution.

2.2 Supported Functions

MService Condition Monitoring covers the following main functions:

• Collection of operational data of the supervised modules

• Collection of all alarms and trips generated in the supervised modules

• Collection of maintenance warnings derived from additional assessment logic related to the su

pervised modules.

• Display of the MNS or MNS iS system structure highlighting modules signaling problems

• Display of historical data in trend displays

• Detailed information on the identification, location, and type of supervised modules

• Online supervision of temperature or power loss related problems within individual cubicles.

MService can supervise all modules in MNS and MNS iS, which are connected to the internal switchgear

communication bus. This includes:

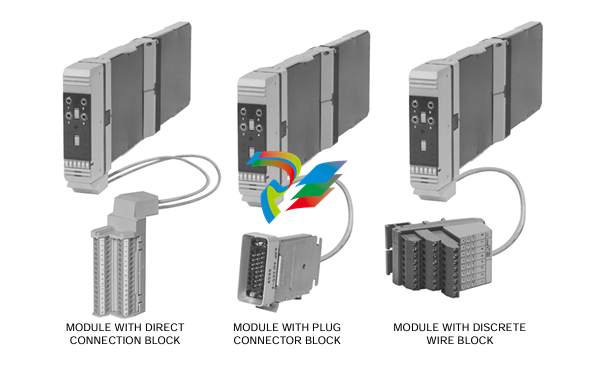

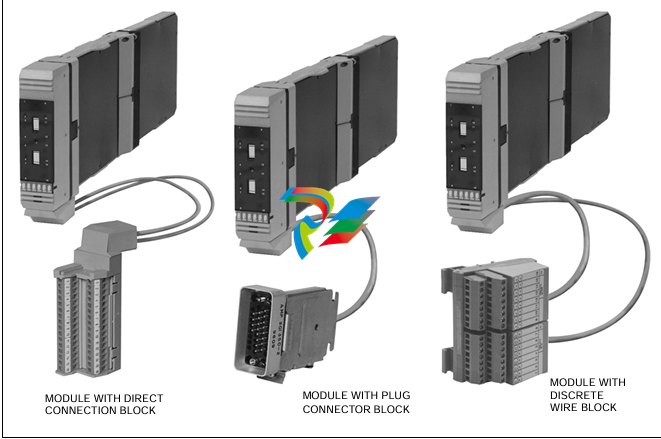

• Motor starter and feeder modules (all sizes), which are equipped with measuring and communi

cation electronic device MControl

• Motor starter and feeder modules (all sizes), which are equipped with intelligent device, UMC

and M10x, communicates to MLink.

• Circuit breakers connected to the switchgear communication with the interface MConnect

• Circuit breakers connected to the switchgear communication with the interface MLink

Excluded from supervision in MService are all modules not connected to the internal switchgear com

munication such as MSpeed (Variable Speed drives in MNS iS) and conventional modules.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)