schneiderInstruction B0123HF and B0123HE Pressure Regulators and B1279UL Air Filter

Introduction

These regulators provide controlled air service to pneumatic instruments. The regulator regulates

a maximum supply pressure of 1.7 MPa (250 psi, 17 bar or kg/cm2) to the nominal levels required

by pneumatic instrumentation.

General

The B0123HF and B0123HE regulators have identical control ranges and are similar in

construction, except that the B0123HE has an integral filter element and drain feature.

Specifications

Installation

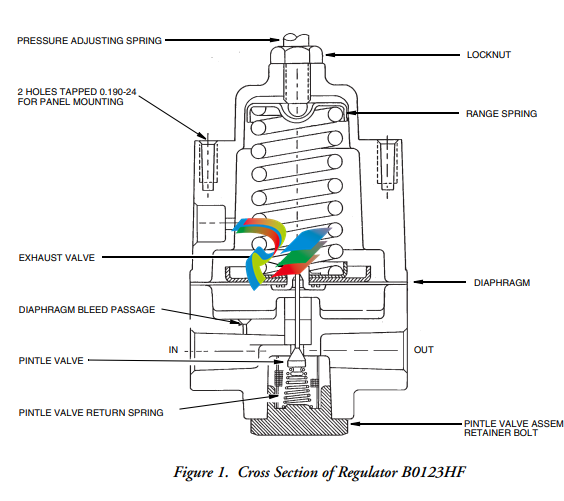

Part No. B0123HF Regulator

Refer to DP 011-158 for overall dimensions. The B0123HF can be supported by the supply and

regulated line piping, or panel mounted. Panel mounting is accomplished by utilizing the two

0.190-24 tapped holes in the top of the regulator. When installing regulator, care should be taken

that the IN and OUT ports are correctly oriented for the piping.

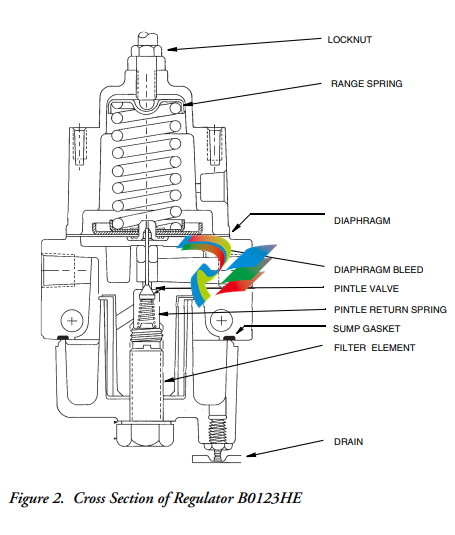

Part No. B0123HE Regulator

Refer to DP 011-157 for overall dimensions. The regulator should be installed as near as possible

to the instrument it is to service. It can be installed either vertically or horizontally, provided the

drain remains located at the lowest point on the assembly. The regulator has two

8 mm (0.320in) diameter holes passing entirely through the body for mounting on a suitable

bracket, or it can be supported by the supply and regulated line piping. It also has two

0.190-24 tapped holes in the body for mounting to a panel.

Operation

To increase pressure, turn the regulator adjustment knob in a clockwise direction. To decrease

pressure, turn the adjustment knob in a counterclockwise direction.

Supply Pressure 1.7 MPa (250 psi, 17 bat or kg/cm2)

Flow Capacity at 700 kPa

(100 psi, 7 bar or kg/cm2)

supply. Regulated to 140 kPa

(20 psi, 1.4 bar or kg/cm2)

33.6 m3

/hr

Sensitivity 25 mmH2O (1 inH2O)

Principle of Operation

(Refer to Figure 1 and Figure 2.)

The range spring, which has been compressed by the adjustment knob and screw, causes the

pintle valve to move downward, allowing air to flow. The pressure builds up against the

diaphragm until the pintle valve throttles. This is the set pressure which is closely maintained in

the following manner: A drop in the regulated line pressure will cause a decrease in the pressure

against the bottom of the diaphragm. The range spring forces the diaphragm down against the

reduced pressure causing the pintle valve to open, admitting more supply air, until the pressure

below the diaphragm balances the spring force. Diaphragm upward motion causes the exhaust

valve in the diaphragm to open. The excess pressure rises into the spring cavity through the

exhaust valve and vents to atmosphere via the exhaust vent.

Maintenance

To install normally replaced parts, the following procedures should be followed.

! CAUTION

Before removing the four cover screws, turn pressure adjusting screw (knob)

counterclockwise on the range spring.

Part No. B0123HF Regulator

1. Remove cover and clean all parts thoroughly.

2. Replace diaphragm and reassemble top assembly.

3. Invert the top assembly and install pintle valve and valve return spring.

Use repair kit, Part No. B0127VS, available from Foxboro. This kit contains a

replacement diaphragm and a pintle valve and spring. Replace air screen and plug

gasket using repair kit, Part No. B0127VV.

Part No. B0123HE Regulator

Periodic cleaning of the filter element is recommended. Shut off the air supply and drain

condensate.

1. Remove the large bolt from the bottom of the regulator and remove sump.

2. Lift out the filter element. Clean all parts thoroughly and reassemble in reverse order

of removal.

Repair Kit, Part No. B0127VS, available from Foxboro, contains a replacement

diaphragm and a pintle valve and spring. Repair Kit, Part no. B0127VT, contains a

resealing gasket, sump bolt washer, and a replacement drain valve.

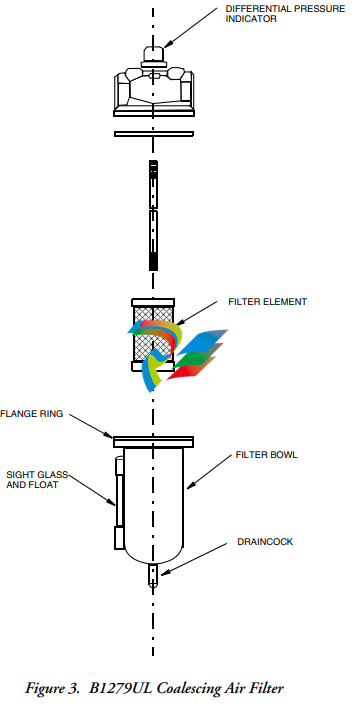

Part No. B1279UL Air Filter

Filter Element Replacement

To replace the filter element, relieve all air pressure from the filter. Unscrew flange ring

(counterclockwise from the bottom), and remove bowl. Remove the bottom adapter and the filter

element. To reassemble, install adapter bottom adapter, bowl, and flange ring,

.

Draining Instructions

To drain, turn draincock on bottom of bowl clockwise from bottom until all liquid is drained,

Turn draincock counterclockwise from bottom to reseal.

Differential Pressure Indicator

When the pressure drop across the filter element reaches 10-12 psi, the red indicators will be in

full view and the element should be replaced. Failure to replace the element when the pressure

drop exceeds 10 psi can be costly, both in terms of reduced air quality due to contaminant reentrapment and the power cost associated with forcing compressed air through an obstructed

filter.