ABBAC 800M Controller Hardware Product Guide

NOTICE

This document contains information about one or more ABB products and may include a

description of or a reference to one or more standards that may be generally relevant to

the ABB products. The presence of any such description of a standard or reference to a

standard is not a representation that all of the ABB products referenced in this document

support all of the features of the described or referenced standard. In order to determine

the specific features supported by a particular ABB product, the reader should consult the

product specifications for the particular ABB product.

ABB may have one or more patents or pending patent applications protecting the intellectual property in the ABB products described in this document.

The information in this document is subject to change without notice and should not be

construed as a commitment by ABB. ABB assumes no responsibility for any errors that

may appear in this document.

In no event shall ABB be liable for direct, indirect, special, incidental or consequential

damages of any nature or kind arising from the use of this document, nor shall ABB be

liable for incidental or consequential damages arising from use of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written permission from ABB, and the contents thereof must not be imparted to a third party nor used

for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and

may be used, copied, or disclosed only in accordance with the terms of such license. This

product meets the requirements specified in EMC Directive 2004/108/EC and in Low Voltage Directive 2006/95/EC.

TRADEMARKS

All rights to copyrights, registered trademarks, and trademarks reside with their respective owners.

Copyright © 2003-2013 by ABB.

All rights reserved.

Release: February 2013

Document number: 3BSE036352-510 A

Electrostatic Sensitive Device

Devices labeled with this symbol require special handling precautions as

described in the installation section.

GENERAL

WARNINGS

Equipment Environment

All components, whether in transportation, operation or storage, must be

in a noncorrosive environment.

Electrical Shock Hazard During Maintenance

Disconnect power or take precautions to insure that contact with energized parts is avoided when servicing.

SPECIFIC

WARNINGS

-50, -63 and Page 70: It is not allowed to manipulate CEX bus base plates

in a powered and running system. Before changing or removing a base

plate, all CEX modules on that segment must be removed.

Page 177: Explosion hazard - Substitution of components may impair

suitability for Class I, Zone 2.

Page 177: Explosion hazard - Do not replace batteries unless the power

has been switched off or the area is known to be non-hazardous.

Page 178: Explosion hazard - Do not disconnect equipment unless the

power has been switched off or the area is known to be non-hazardous.

SPECIFIC

CAUTIONS

Page 13: This Product guide does not contain last-minute product information and updates which might affect functionality and/or performance.

For information on late changes and restrictions, please refer to the

Release Notes, Control Software for AC 800M (3BSE021377*).

Page 54: Always check that the CPU and other hardware units have the

correct firmware version, before installing them. If the CPU is empty, CPU

firmware must be loaded via the COM4 port.

SPECIFIC

CAUTIONS

(continued)

Page 175: If you use other power supplies, except SD82X and SD83X, to

provide the 24V d.c. for AC 800M it is required that they also are CE

marked, UL listed and fulfill the LVD (SELVand PELV).

Page 176: The AC 800M modules are to be considered as open equipment, according to EN 61131-2 and UL508, and must be mounted in

non-public localities.

General

This Product Guide is primarily intended for sales representative within ABB.

An additional user group may be internal ABB customers and important external

customers, using the Product Guide as a complement to existing product

information.

Document Conventions

Microsoft Windows conventions are normally used for the standard presentation of

material when entering text, key sequences, prompts, messages, menu items, screen

elements, etc.

Warning, Caution, Information, and Tip Icons

This publication includes Warning, Caution, and Information where appropriate

to point out safety related or other important information. It also includes Tip to

point out useful hints to the reader. The corresponding symbols should be

interpreted as follows:

This Product guide does not contain last-minute product information and updates

which might affect functionality and/or performance. For information on late

changes and restrictions, please refer to the Release Notes, Control Software for

AC 800M (3BSE021377*).

Electrical warning icon indicates the presence of a hazard which could result in

electrical shock.

Warning icon indicates the presence of a hazard which could result in personal

injury.

Caution icon indicates important information or warning related to the concept

discussed in the text. It might indicate the presence of a hazard which could

result in corruption of software or damage to equipment/property.

Information icon alerts the reader to pertinent facts and conditions.

Tip icon indicates advice on, for example, how to design your project or how to

use a certain function

Although Warning hazards are related to personal injury, and Caution hazards are

associated with equipment or property damage, it should be understood that

operation of damaged equipment could, under certain operational conditions, result

in degraded process performance leading to personal injury or death. Therefore,

fully comply with all Warning and Caution notices.

Terminology

A complete and comprehensive list of terms is included in System 800xA System

Guide Functional Description (3BSE038018*). The listing includes terms and

definitions that apply to the 800xA System where the usage is different from

commonly accepted industry standard definitions and definitions given in standard

dictionaries such as Webster’s Dictionary of Computer Terms.

Applicable Specifications

EUROPEAN UNION DIRECTIVE COMPLIANCE

Units mentioned in this document for which the product is marked with the

logo comply with the EMC Directive EMCD 2004/108/EC and the Low

Voltage Directive LVD 2006/95/EC. See Appendix C, Directive Considerations.

UL LISTING

Units mentioned in this document are UL listed if the product is marked with the UL

logo.

indicates UL approval for the USA, and for both Canada and

the USA. The logo indicates UL approval for Canada only.

The applied standard is UL508, Industrial Control Equipment. Units approved for

use at hazardous locations also comply with the standard UL60079-15. To fulfill the

UL requirements for hazardous locations, the instructions in Appendix D, Standards

must be followed.

TÜV Approval

Units mentioned in this document are TÜV qualified for IEC 61508 SIL2 or SIL3 if

the product is marked with the TÜV logo.

Released User Manuals and Release Notes

A complete list of all User Manuals and Release Notes applicable to System 800xA

is provided in System 800xA Released User Manuals and Release Notes

(3BUA000263*).

System 800xA Released User Manuals and Release Notes (3BUA000263*) is

updated each time a document is updated or a new document is released. It is in pdf

format and is provided in the following ways:

• Included on the documentation media provided with the system and published

to ABB SolutionsBank when released as part of a major or minor release,

Service Pack, Feature Pack, or System Revision.

• Published to ABB SolutionsBank when a User Manual or Release Note is

updated in between any of the release cycles listed in the first bullet.

A product bulletin is published each time System 800xA Released User Manuals

and Release Notes (3BUA000263*) is updated and published to ABB

SolutionsBank.

Section 1 Overview

Introduction

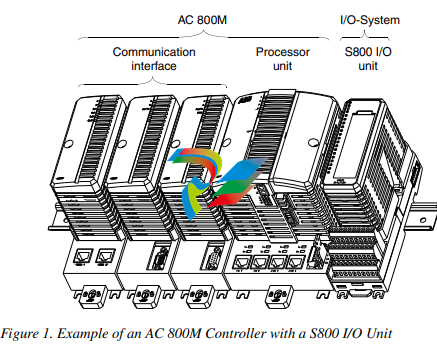

AC 800M can be defined as a hardware platform consisting of individual hardware

units. AC 800M hardware platform can be programmed to perform multiple

functions, depending on the specific unit configuration and operating system

selected.

The hardware units which form the AC 800M Controller are:

• Processor units (including base plates)

• Communication interfaces for different protocols (including base plates)

• Power supply units, providing various power output levels

• Battery back-up unit

• For High Integrity systems control applications with AC 800M HI, special

module SM810/SM811, is needed

Once configured, the AC 800M hardware platform effectively becomes

the AC 800M Controller.

Equipped with the specified Control Software, the AC 800M Controller can be used

for all kinds of process and industrial automation applications. With Control

Software, the controller can act either as a stand alone process controller or as a

controller, performing local control tasks, in a control network consisting of many

interconnected computers.

The AC 800M Controller is delivered without firmware. To provide the controller

with Control Software, it will first be necessary to load the firmware and create

the application separately by using the Control Builder interface.

The AC 800M Controller consists of a selection of units mounted on horizontal DIN

rails, as shown in Figure 1 on page 18, which can, if required, be housed within

an enclosure.

The majority of units consist of a base mounting plate and a removable cover, which

are attached to each other by means of screws. The base plate, which is always

mounted on the DIN rail, carries the majority of the connections to the processor,

power supplies and communication interfaces, as well as to the external buses and

systems

The processor unit used for the AC 800M HI Controller is physically identical to

other AC 800M controllers, simplifying service and spares support and providing

flexibility during the project build phase. The HI functionality is extended by the

addition of a SM810/SM811 and the SIL certified software license only. This

enables non-critical control schemes to upgraded to SIL certified schemes by the

addition of a plug-in SM810/SM811, plus selection of the appropriate license.

The basic unit for a AC 800M HI consists of PM865 and SM810/SM811,

see Figure 2.

Product Benefits

Some of the benefits of the AC 800M Controller are:

• Flexibility, the AC 800M Controller can be ordered as individual units which

may be mounted in accordance with the customers own requirements.

• Extremely small footprint.

• Simple DIN rail attachment / detachment procedures, using the unique slide

& lock mechanism.

• Modularity, allowing for step-by-step expansion. You only pay for what you

require at the present time.

• Reliability and simple fault diagnosis procedures.

• Controller redundancy for higher availability (CPU, CEX-Bus, communication

interfaces, S800 I/O).

• Built-in redundant Ethernet Communication ports.

• Built-in RS-232C communication ports.

• Low power consumption, thus no external fans required.

• Flexible process connection, using either local I/O or standard fieldbuses.

• S800 I/O redundancy.

• Supports S800 I/O High Integrity (with PM865 only).

Features

The major features of the AC 800M are:

• High performance and large application memory.

• Extensive availability.

• CPU redundancy (PM861/PM864/PM865/PM866,PM891).

• AC 800M High Safety Integrity Level 2 certified using PM865/SM810/SM811.

• AC 800M High Safety Integrity Level 3 certified using PM865/SM811.

• Built-in redundant Ethernet channels.

• Built-in RS-232C channels.

• Sectioned CEX-Bus using a pair of BC810.

• Quick and simple fault-finding with the aid of LEDs on each unit / channel.

• Built-in battery back-up of memory (except for PM891).

• External battery back-up.

• Use of industry standard power supply voltage - 24V d.c.

• Easy mounting on standard DIN rail.

• IP20 Class protection without the requirement for enclosures.

• Incorporation of a wide variety of communication possibilities.

• Hardware based on standards for optimum communication connectivity

(Ethernet, PROFIBUS DP).

• Support for PROFIBUS DP fieldbus.

• Support for FOUNDATION Fieldbus.

• Support for Advant Fieldbus 100.

• Support for Modbus TCP.

• Support for Field Device Tool (FDT) and Device Type Manager (DTM)

concept for tool routing of HART instruments.

• Support for connection to INSUM via Gateway (Ethernet/LON)

• Support for IEC 61850.

• Support for PROFINET IO.

• Support for EtherNet/IP.

• Support for connection to S100 I/O.

• Support for connection to Satt I/O.

• Support for TRIO/Genius.

• Support for Genius remote I/O discrete, analog and high-speed counter blocks.

• Support for ABB Drives via PROFIBUS, ModuleBus and DriveBus.

• Support for connection to MasterBus 300.

• Full EMC certification.

• Selected units UL certified (UL508 as open equipment, and for hazardous

locations according to UL60079-15 (Class 1 Zone 2)).

Section 2 Functional Description

Processor Unit - General

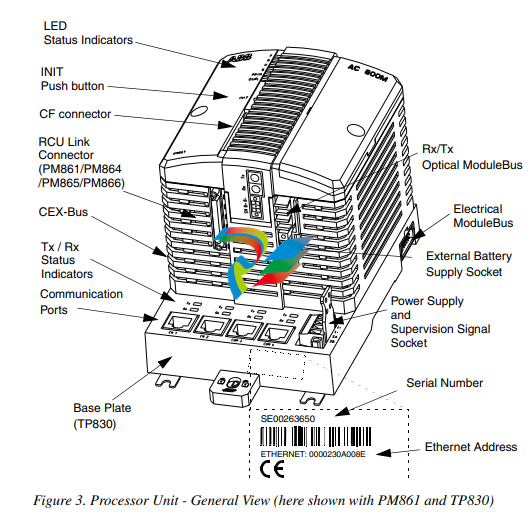

The processor unit (except PM891) consists of two parts:

• Processor unit,

PM851/PM851A/PM856/PM856APM860/PM860A/PM861/PM861A/PM864

/PM864A/PM865/

PM866, equipped with power supply and CPU-boards

• Base plate, TP830, with a unit termination board.

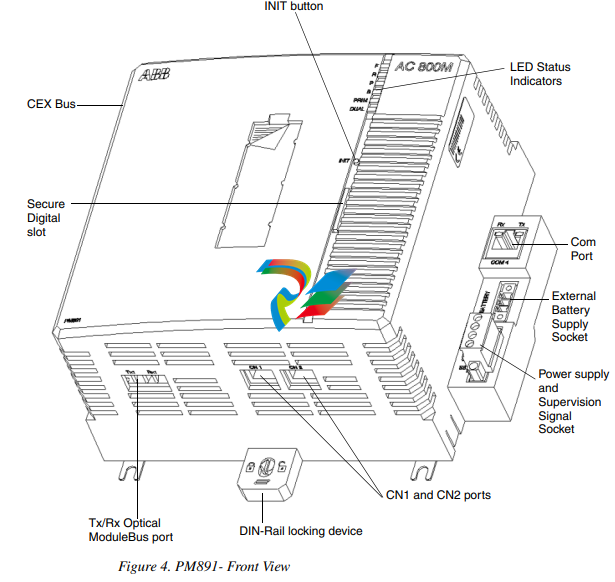

The PM891 processor unit is a monolithic unit equipped with power supply and

CPU-boards, and unit termination.

The CPU board contains the microprocessor and the RAM-memory. The memory

holds an executable version of the firmware, the controller system configuration and

an application program.

The processor unit also has an optical ModuleBus used for connecting additional

clusters of S800 I/O, and a connector housing for a plug-in backup media (Secure

Digital card for PM891, and Compact Flash card for other processor units).

PM851 is equivalent to PM856 unless stated otherwise.

PM861A and PM864A are equivalent to PM861 and PM864 respectively, unless

stated otherwis

PM8xx Unit (Except PM891) The base plate of PM8xx unit (except PM891) has two RJ45 Ethernet ports (CN1, CN2) for connection to the Control Network, and two RJ45 serial ports (COM3, COM4). One of the serial ports (COM3) is an RS-232C port with modem control signals, whereas the other port (COM4) is isolated and used for the connection of a configuration tool. Both the electrical ModuleBus and the communication expansion bus (CEX-Bus) connectors are mounted on the base plate. The built-in electrical ModuleBus can be used in single CPU configuration for connecting one cluster of S800 I/O units directly to the base plate (maximum number of units per cluster is 12). However, an additional seven clusters (each comprising up to 12 units) can be added to the optical ModuleBus. The CEX-Bus is used for extending the on-board communication ports with communication interface units. It is also possible to use redundant communication interfaces on the CEX-Bus. The CEX-Bus Interconnection unit BC810 is used to increase the availability on the CEX-Bus by dividing it into separate segments. All base plates are provided with a unique Ethernet address which provides every CPU with a hardware identity. The address can be found on the Ethernet address label attached to the TP830 base plate, as shown in Figure 3 on page 25. Note that a PM851/PM851A is restricted to one Ethernet (CN1) port, thus redundant Ethernet is not available

The PM891 unit has two RJ45 Ethernet ports (CN1, CN2) for connection to the Control Network, and one RJ45 serial port (COM4). The COM4 port is isolated and is used for the connection of a configuration tool. The communication expansion bus (CEX-Bus) is mounted on the unit. The CEX-Bus is used for extending the on-board communication ports with communication interface units. It is also possible to use redundant communication interfaces on the CEX-Bus. The CEX-Bus Interconnection unit BC810 is used to increase the availability on the CEX-Bus by dividing it into separate segments. The optical Modulebus at the bottom of the unit can be used for connecting seven clusters of S800 I/O units (each comprising up to 12 units). Each PM891 unit is provided with a unique Ethernet address which provides hardware identity to the unit. The address can be found on the Ethernet address label located on the right-hand side of the unit.

Following a changeover, the system operates as a system without redundancy with

only one processor unit in operation. You can replace the malfunctioning processor

unit while the system is running. After the replacement is carried out, the system

once again has a redundant processor unit.

If an error arises in the backup unit, you can also replace the backup unit while the

system is running.

Errors which occur in the backup unit can never affect the primary unit's operation.

The primary unit and the backup unit are logically separated from one another.

Hardware errors in the primary processor unit cause the system to perform a correct

changeover. These hardware errors are "single errors".

The application programming and the communication are totally unaffected by the

redundancy.

The serial port COM3, can not be used in redundant CPU configuration.

S800 I/O units are connected to the two CPUs by the optical ModuleBus. The

built-in electrical ModuleBus on the base plates can not be used for connection of

S800 I/O in redundant CPU configuration.

Communication

The number of ports and protocols, provided by the processor unit, can be expanded

by adding communication units to the CEX-Bus.

Examples of unit types that may be connected to the CEX-Bus are as follows:

• FOUNDATION Fieldbus High Speed Ethernet (FF HSE)

• PROFIBUS DP

• Dual RS-232C ports

• S100 I/O

• INSUM

• IEC 61850

• MasterBus 300

• Modbus TCP

• ABB Drives via DriveBus Interface

• TRIO/Genius

• Satt I/O via ControlNet (19” Satt rack I/O, S200 I/O and S200L I/O)

• AF 100

• PROFINET IO

• EtherNet/IP

This expansion provides the means of connecting remote I/O, fieldbus instruments

and additional RS-232C ports.

Battery Back-up

A battery is used to power the back-up for both the RAM and the real time clock in

the case of a power failure. Battery back-up can be provided in two ways:

• using the internal battery (as shown in Figure 6 on page 33). The internal

battery is not available in PM891.

• using an external battery unit, (SB821), for longer back-up times.

• using an external rechargeable battery unit, (SB822), for longer back-up times.

The external battery unit is mounted on the DIN rail and connected to the CPU via a

cable.

Power Supply

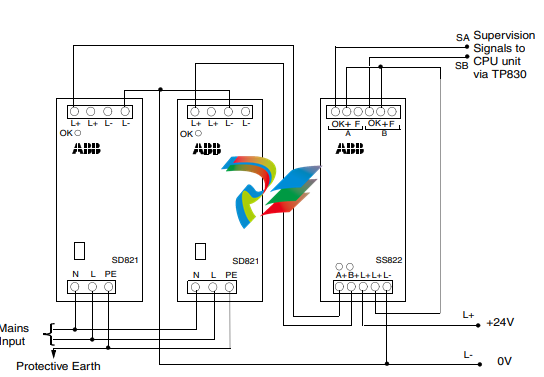

The power supply units (SD83x) are switch-mode power converters that convert a.c.

mains supply voltage to a regulated 24 V d.c. The mains input supply voltage can

either be 115 V a.c. or 230 V a.c. and is selected using a switch, mounted on the

front panel of the unit.

The power supply units can be used in both redundant and non-redundant

applications. When redundant power supply units are connected to a common load,

a voting device, (SS823), must be used to combine the two outputs to a single

output, via diodes. The redundant power supply units may be connected to

completely separate mains supplies or to the same mains supply, depending on the

configuration selected.

The L- output (0 V) of the power supply units can be used without being grounded.

If grounding is required, the power supply unit L- output (0 V) can be grounded

directly or via a suitable resistor.

The processor unit has no requirement for an uninterruptible power supply in order

to shut down safely. The processor unit has an internal power reservoir that lasts for

5 ms, which is sufficient for it to make a controlled power down. The power supply

units easily handle short power interruptions (<20 ms) that can normally occur

within any industrial environment. Despite this, it is sometimes necessary to protect

certain applications, from brief voltage failures, by installing Uninterruptible Power

Supply (UPS) devices.

For information on SD83x, refer to Power Supply Units - SD831, SD832, SD833,

and SD834 on page 102.

Powering from an External Source

The AC 800M Controller can be powered from an external +24 V DC source. This

source is often common for many different types of plant equipment, resulting in

long power cables to the AC 800M Controller. Furthermore, heavy load changes can

cause variations in controller supply voltage making it necessary to take precautions

against low voltage in order to prevent controller malfunction.

Should there be a risk that the +24 V at the PM8xx power terminals could drop

below 19.2 V for more than 1 ms, then an energy reservoir must be used for

Powering Units.

ABB strongly recommends using a DC/DC converter and extra energy reservoir in

case external DC-supply with longer cables than 10 m is used.

I/O System

There are several methods of connecting I/O systems to the AC 800M Controller:

• S100 I/O via CI856.

• S800 I/O units via the ModuleBus. Support for hot configuration during run,

redundancy on all levels, HART routing, and Sequence-of-Events (SOE).

• S800 I/O units via CI854/CI854A and CI840, PROFIBUS DP. Support for

HART routing, redundancy on all levels, and hot configuration during run.

• S800 I/O units via CI854/CI854A and CI801, PROFIBUS DP. Support for

HART routing, and hot configuration during run.

• S900 I/O units via CI854/CI854A, PROFIBUS DP.

• ABB Drives can be connected to the ModuleBus, via CI801. Some Drives

equipment can be connected directly to PROFIBUS or PROFINET IO. Please

refer to Drives-specific documentation for more information.

• Genius remote I/O (TRIO) via the CI862.

• Satt I/O on ControlNet (19” Satt rack I/O, S200 I/O and S200L I/O) via the

CI865.

• PROFINET IO via CI871

For further information about supported I/O-units, refer to I/O-specific

documentation, see Released User Manuals and Release Notes on page 16.

S800 I/O

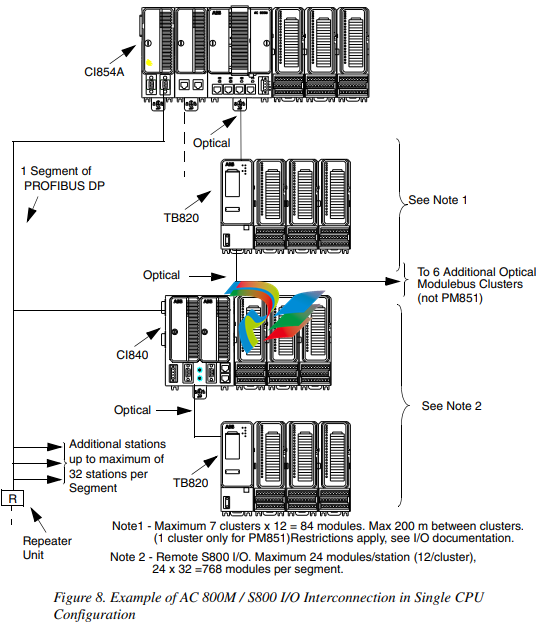

See Figure 8 on page 40 for examples of AC 800M / S800 I/O interconnection.

The top right area of Figure 8 on page 40 shows one cluster (or group) of units,

connected to the built-in electrical ModuleBus of an AC 800M Controller. The

maximum number of units per cluster is 12. However, a further seven clusters, each

comprising of up to 12 units, can be added to the optical ModuleBus. This results in

a total count of 96 units for the local ModuleBus.

S100 I/O

S100 I/O are connected to the AC 800M, via the communication unit CI856. A bus

extension cable TK575/TK580, together with DSBC174/DSBC176 or DSBC173A,

connects the S100 I/O units to the base plate, TP856, of CI856. Up to five S100 I/O

racks can be connected to the CI856.

Redundant S100 I/O bus extension can not be connected to CI856.

S900 I/O

S900 I/O are connected to the AC 800M, via PROFIBUS DP and CI854/CI854A.

The S900 I/O system is a remote I/O system for use in hazardous areas. Due to its

explosion protection certificates, the S900 process I/O system can be installed in

both hazardous areas (zone 1 and zone 2) and safe areas.

Other I/O Systems

A PROFIBUS DP segment (or node), shown on the top left-hand side of Figure 8 on

page 40, allows for a large increase in the numbers of units connected to each

AC 800M Controller. The segment is shown here with a Fieldbus Communications

Interface (FCI) unit (type CI840), connected to the PROFIBUS DP network. The

use of FCI units, or other types of adapters, allows the selection of units from

several I/O families.

In redundant CPU configuration, connection of S800 I/O is done only with the

optical ModuleBus. See Figure 9 on page 41. Each cluster of I/O units is

connected to two TB840s. Each processor unit is connected to one of the

TB840s. Note that the built-in electrical ModuleBus can not be used in redundant

CPU configuration.

Note that a PM851/PM851A is restricted to one optical ModuleBus cluster.

Genius remote I/O (TRIO)

TRIO is a remote I/O product that provides discrete, analog and high-speed counter

blocks for connection to the AC 800M. Configuration of the I/O block units and the

CI862 is done using Control Builder M.

The CI862 Communication Expansion Module (CEM), connects a TRIO Field Bus

to the controller AC 800M. The connection between CI862 and AC 800M is done

via the CEX-Bus.

A single CI862 can connect 30 blocks to a single LAN. The AC 800M can have up

to four single lans or four redundant lans. The maximum I/O with TRIO in an

AC 800M is 1000 IO points.The CI862 can be set redundant.

TRIO blocks, are self-contained, configurable I/O blocks used to interface field

devices to the CI862 communications bus. These blocks can be individually

installed on machines, in junction boxes, or grouped in racks or panels. A TRIO

block is made of cast aluminum, and weighs approximately 1.8 kg (4 pounds). It

measures approximately 22.5 x 10 x 7.5 cm (9 x 4 x 3 inches). Each block has its

own communications capability and microprocessor, and provides from 6 to 32

circuits for connecting input and output devices. You can place blocks on the bus in

any combination or sequence. You can use a mix of blocks on the same bus.

Satt I/O interface

The Satt I/O system consists of Rack I/O and Series 200 I/O family (S200 I/O,

S200L I/O and I/O 200C). CI865 connects to Rack I/O, via the adapter 200-RACN,

and to Series 200 I/O family, via the adapter 200-ACN.

The CI865 module is the AC 800M system’s communication interface for

Satt ControlNet and bridges different bus standards used on AC 800M and

Satt ControlNet. The CI865 module makes it possible to use older Satt I/O system

(Rack I/O and Series 200 I/O) with the AC 800M controller platform but it can not

be used as a general ControlNet interface. CI865 supports online replacement (Hot

Swap), and does not require any configuration before installation.

CI862 cannot be used in an AC 800M High Integrity controller

CI865 cannot be used in an AC 800M High Integrity controller.

FOUNDATION Fieldbus High Speed Ethernet (FF HSE)

The FF HSE communication interface unit CI860 makes it possible for AC 800M

controllers to communicate with FF HSE devices via Ethernet. The FOUNDATION

Fieldbus Linking Device LD 800HSE (see Appendix B, Recommended

Components) makes it possible for AC 800M controllers to communicate with

FOUNDATION Fieldbus H1 devices, via CI860 and Ethernet. An example system

structure with a single CPU is given in Figure 10 on page 42. An example system

structure with a redundant CPU is given in Figure 11 on page 43.

CI860 cannot be used in an AC 800M High Integrity controller.

The following schematic figures, with examples of I/O interconnections, do not

necessarily show the exact amount of connectors or their exact positions.

Drive System

ABB Standard (Std) and Engineered (Eng) Drives can be connected to AC 800M

through any of the following:

• The optical ModuleBus

• CI801 and PROFIBUS DP

• NPBA-12, RPBA-01, or FPBA-01 PROFIBUS DP Adaptor modules along

with CI854

• RETA-02 or FENA-01/-11 Ethernet Adapter modules along with CI871

(PROFINET IO)

• CI858 DriveBus Interface. .

ModuleBus

In single CPU configuration, ABB Drives can be connected to the processor unit via

the optical ModuleBus. See Figure 12 on page 47. The number of ABB Drives

which can be connected to the optical ModuleBus, can be described by the

following equation:

(No. of ABB Drives) < 84 - (12 x (No. of TB820s))

that is, each Drive uses one ModuleBus cluster.

PROFIBUS

In single and redundant CPU configuration, ABB Drives can be connected via

PROFIBUS DP and CI801. See Figure 12 on page 47. Only Standard Drives can be

connected to CI801. Fourteen (14) Standard Drives can be connected to each CI801

if there are no I/O units connected. For the number of Drives that can be connected

to the same CI801, when both I/O units (TB820) and Standard Drives are

connected, refer to documentation about FCI for PROFIBUS DP.

For more information about ABB Drives and its types (Std and Eng) refer to

S800 I/O documentation.

For information about Branching Unit (See Figure 12 on page 47) see ABB Drive

System documentation.

CI858 cannot be used in an AC 800M High Integrity controller.

ABB drives can also be connected via PROFIBUS DP (CI854/CI854A), with direct

connection to PROFIBUS DP slave modules NPBA-12, RPBA-01, and FPBA-01.

PROFINET IO and CI871

The RETA-02 Ethernet Adapter module and FENA-01/-11 Ethernet Adapter

module are optional devices for ABB drives, which enables the connection of the

drive to a PROFINET IO (PNIO) network. The drive is considered as a PNIO device

on the PROFINET IO network, and it is compatible with all PNIO controller

stations that support PROFINET IO and sub-slots.

DriveBus Interface

ABB drives can be connected to the AC 800M via the CI858 unit, see Figure 12 on

page 47 and Figure 13 on page 48. The drive interface can be used for controlling up

to 24 drives or inverter units.

Main communication functions of the drive connection are:

• dataset communication

• broadcast system time

• supervision and diagnostics functions

The data exchange between the AC 800M and the CI858 consists of eight datasets.

The drive connection is able to transfer at the maximum 8 datasets / 1 ms.

Connection of multiple drives requires the use of a branching unit, which enables

the construction of a logical bus with physical star topology, see Figure 13 on page

48. The branching units can be chained.

The following drives are supported by the drive connection:

• ACS 600 single drive

• ACS 600 multi drive

• ACS 600 thyristor supply units

• ACS 600 IGBT supply units

• ACS 800 product family

• ACS 140-AC S400

• DCS 600 and DCS 400

• ACS 6000 product family / large drives

• ACS 1000 product family

For more information about ABB Drives and its types (Std and Eng) refer to

S800 I/O documentation, see Released User Manuals and Release Notes on page

16.

For information about Branching Unit (Figure 13 on page 48) see ABB Drive

System documentation.

The following schematic figures, with examples of I/O interconnections, do not

show the placement of the connectors.

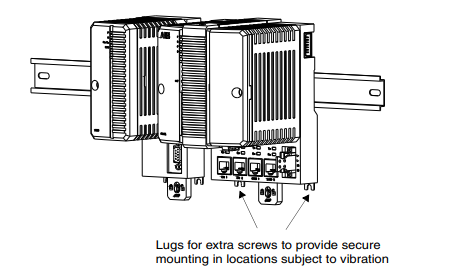

Installation

The AC 800M Controller consists of units that are mounted on a horizontal DIN rail

as shown in Figure 16 on page 51. Each base plate has a locking device that ensures

contact between the metal back plate and the DIN rail, providing an effective ground

connection.The locking device can be set to any of the following three positions,

OPEN, SLIDE or LOCKED, which makes installation and removal of the base

plates very simple.

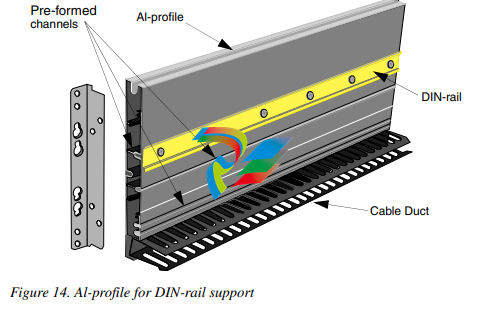

There are two ways of mounting the products concerned in cabinets, open rack or

other types of installations; aluminum profile with mounted DIN-rail, see Figure 14,

or DIN-rail mounted on a metal sheet of proper size, see Figure 15.

The aluminum profile or metal sheet shall be properly connected to protective earth.

DIN-rail type with height 7.5 mm shall be used. Refer to type NS 35/7.5 according

to standard EN 50022.

Figure 15. Mounted on Metal Sheet

It is not allowed to manipulate CEX bus base plates in a powered and running

system. Before changing or removing a base plate, all CEX modules on that

segment must be remove

The AC 800M and S800 I/O-units have protection class IP 20. If a higher IP class is

required, an additional enclosure is needed

Configuration

Using the Control Builder interface, it is possible to download controller firmware

and configure hardware (I/O and communication units). It is also possible to make

application programs with IEC61131-3 and compile and run programs off-line, as

an aid to process simulation, before finally downloading an application to the

controller.

The Control Builder interface is part of the Industrial IT 800xA System, which runs

on a PC and is normally connected to the AC 800M controller via the Control

Network, using the CN1 or CN2 port on the AC 800M controller. Alternatively, the

PC could be connected to the controller via the controller COM4 port (RS-232C). In

that case, use the tool cable TK212 and a serial port on the PC.

Note that a PM851/PM851A is restricted to one Ethernet (CN1) port, thus

redundant Ethernet is not available.

Note that Control Builder as standard does not support CI862. If CI862 is to be

used, suitable system extension must be installed.