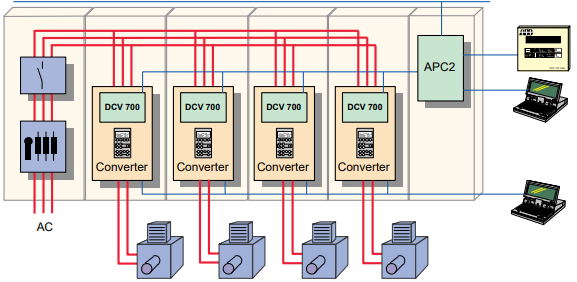

ABBDCV 700 thyristor panelsfor 6-/ and 12-pulse DC drive systems in Drive-MNS-cabinets 22 to 5150/10300 A 10 to 4900/9400 kW

Latest Technology, High Performance, and a User Friendly Concept – the New DCV 700 Series The DCV 700 series is a complete range of DC converters intended for the supply and control of DC machines, in stand-alone or multi-drive systems with high performance and reliability specifications. Wide Variety of Industrial Applications The DCV 700 series can handle the most demanding applications in: • rolling mills • pulp and paper • metals (casters, processing lines etc.) • material handling (cranes, hoists etc.) Digital Control To meet the most stringent control requirements, the DCV 700 features speed control, which reduces the effects from gear backlash and torsional vibration arising in mechanical systems. High-performance speed and torque control will fulfill all requirements for rapid response and control accuracy. Autotuning for armature current control will simplify the commissioning procedure. DCV 700 converters are fully digital and mounted in an enclosure complete with all necessary equipment, meeting the most stringent safety standards. The converter can be used for standard applications but has the flexibility to be customized for the most demanding applications. Comprehensive Product Range DCV 700 converters are available as 6-/ and 12- pulse 2- or 4-quadrant, in a current range 22 to 5150/10300 A and supply voltages of 200 to 1000 VAC. A selection of options is available to provide the user with a system meeting the most demanding technical requirements and performance expectations. Common control electronics throughout the range reduces spare parts inventory and training requirements.

Diagnostics Digital control allows comprehensive diagnostics, including for example detection of • overcurrent • overvoltage • earth faults Troubleshooting is easily undertaken via the Control Panel and the Commissioning and Maintenance Tools.

Commonality with AC Drives – Flexible System Configurations Some of the most important features and benefits common to both the DC and AC drives are: • application control system (APC) – fewer spare parts • link to automation systems • commissioning, maintenance and programming tools – less training • control panel – quick information • drive-MNS cabinets – standardization benefits; possibility to build mixed systems • EMC design available

Basic Functionality Figure 2. Drive and Torque Control, block diagram The thyristor bridge can be 2-quadrant (6 thyristors) or 4-quadrant (12 thyristors). For current ratings up to 700 A the thyristor bridge consists of integrated thyristor modules – more compact, cost effective, less components – so the fuses are installed outside the module, in the supply line. For higher current ratings, disc thyristors are used, so there is a branch fuse for each thyristor. Each thyristor is protected by a snubber circuit. AC voltage, AC current and DC voltage are monitored. These measurements are utilized by the converter software for supervision and protection. Overvoltage protection by means of varistors is also provided. Converters are always equipped with a cooling fan integrated in the converter module. The monitor and protective features, provided as standard and listed below, have been designed, keeping in mind, personnel safety, equipment integrity and continuity of the process. Motor: Loss of speed feedback Overtemperature Overload Overspeed Stall Armature overcurrent Armature current ripple Armature overvoltage Minimum field current Field overcurrent Converter: Thyristor temperature Supply: Main supply undervoltage Auxiliary supply undervoltage Wrong phase sequence The converter includes emergency stop and prevention of unexpected start-up as standard protective functions. The software also includes a fault logger storing up to 100 faults in real time. Information on internal signals is stored in the data logger and it can be displayed by the Commissioning and Maintenance Tool for easy fault finding. Converter software for application, drive, and torque control Drive Control receives either speed or torque reference and gives a torque reference to the Torque Control. Torque Control is controlling the armature current, the field current and the EMF. It receives the torque reference from the Drive Control or from the Application Controller (APC). Auto/manual tuning for armature current simplifies the commissioning and makes the tuning procedure flexible. Fully controlled thyristor bridges with many protection features offer the highest reliability and operational safety.

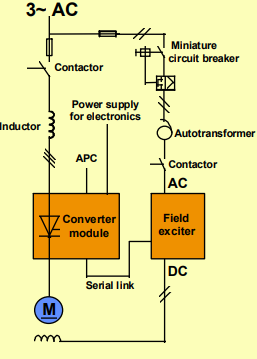

Field Exciters 2-phase, 4-quadrant, outside the converter module, 50 A Full controlled thyristor bridge, microprocessor controlled, with separate power supply (115/230 VAC) for the control electronics. To achieve high resolution in current measurement, the same solution as in the half controlled 50 A field exciter is used. This design offers field reversal and extra forcing possibilities. For steady state the full controlled bridge is working in half controlled mode in order to minimize voltage ripple. For fast changes of field current the bridge is working in full controlled mode. Insulation voltage 700 V, operation voltage ≤ 500 V (for operating voltages higher than 500 V an adaptation via T3 autotransformer is available). 3-phase, 2/4-quadrant, 22 ...450 A This field exciter is used for converter ratings of 2050...5150 A. For field current ratings above 50 A an external enclosed field exciter will be used. Current ratings are same as the armature current max. 450 A at 500 V AC and max. 400 A at 600 V AC. Several Solutions • Ratings from 6 to 450 A • Integrated, separate or external • 2-phase or 3-phase versions • Digital control • Auto/manual tuning In the DCV 700, an autotransformer is included to reduce voltage ripple in the field circuit by adapting the AC voltage to a suitable level. The field exciters are controlled via a serial link with a speed of 62.5 kBaud for fast and accurate control. Fig. 3 shows the connections of the field exciter. Diode Field Exciter 2-phase, integrated in the converter module, 6 A The diode field exciter is a diode bridge rated up to 6 A with internal minimum field supervision, without any need for adjustment. Digital Controlled Field Exciters 2-phase, 1-quadrant, integrated in the converter module, 16 A (max. 6 A in converter modules up to 50 A max. 8 A in converter modules up to 75 A, max. 16 A in converter modules 110...700 A) Half controlled thyristor/diode bridge, microprocessor controlled with the electronics supplied from the armature circuit converter. To achieve high resolution in current measurement, the current feedback can be adapted to different current levels such as 3, 5, 7, 9, 11, 13, 15, 17 A. Insulation voltage 600 V, operation voltage ≤ 500 V. 2-phase, 1-quadrant, outside the converter module, 50 A Half controlled thyristor/diode bridge, microprocessor controlled, with separate power supply (115/230 VAC) for the control electronics. To achieve high resolution in current measurement, the current feedback can be adapted to different current levels such as 3, 5, 7, 9, 11, 13, 15, 17, 21, 27, 33, 39, 45, 50 A. Insulation voltage 700 V, operation voltage ≤ 500 V (for operating voltages higher than 500 V an adaptation via T3 autotransformer is available)

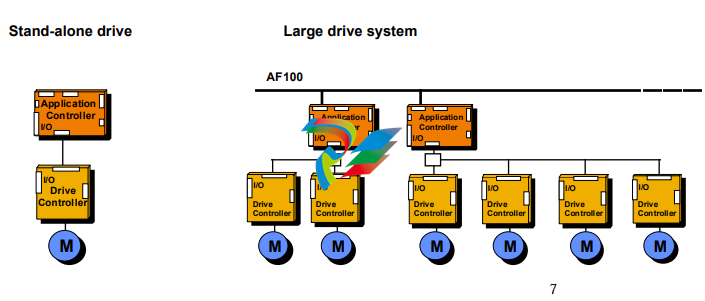

Control Configuration The control system provides a flexible and simple method of controlling different drive configurations. The configurations comprise the converter and its software, Application Controller, Engineering and Maintenance tools and different communication links to other automation systems. The control system includes an Application Controller (APC) and a Digital Drive Controller (DDC) with well defined functions and interface. The Application Controller (APC), common for both AC and DC drives, is a single board controller with all the software and hardware facilities needed to handle the application specific functions. The Digital Drive Controller (DDC) is not programmable but various functions and operating modes can be selected by a fixed number of parameters, which are set from the APC level. The motor control programs are located in the DDC, which is controlled by either a torque or a speed reference provided by the APC.

Stand-alone drive A single drive has one Digital Drive Controller DDC connected to the Application controller APC. Small drive system In small systems, one APC is connected from 1 up to 4 Digital Drive Controllers. The small drive configuration can also be used in master/slave applications. Large drive system Large systems are built by interconnecting application controllers through a communication bus, for example AF100. Common control functions can be distributed to separate nodes. Even very complex systems can be configured by using the same system design concept and its common building blocks, resulting in great savings in, for example, spare parts.

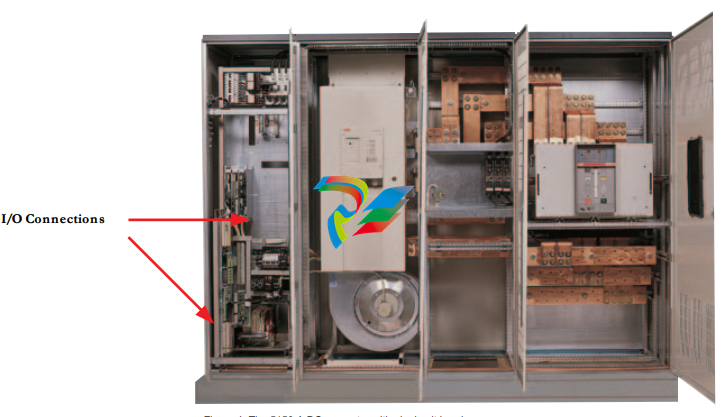

The I/O connections of the DCV 700 are in the Application Controller (APC) and in the Digital Drive Controller (DDC). The Application Controller APC includes: • 4 digital inputs • 2 digital outputs • 2 analogue inputs • 1 voltage reference output The I/O connections in the Drive Controller DDC are used for safety and other drive specific functions like emergency stop and motor temperature measurement: • 3 digital inputs • 4 digital outputs • 5 analogue inputs • 2 analogue outputs • 1 pulse encoder input • 1 emergency stop input • 1 emergency stop output • 1 current source • 1 voltage reference output • 1 actual armature current output Optional I/O boards are available to provide tailored solutions for the most demanding applications. The quantity of I/Os can be increased by using extended I/O board and speed measurement board. Extended / Remote I/O Board YPQ110A Connection to the APC can either be through parallel bus (extended) or through low speed serial bus (remote). • 8 digital inputs • 8 digital outputs • 4 analogue inputs • 2 analogue outputs • 3 voltage reference outputs Speed Measurement Board YPH107A The board can be used for accurate speed and position measurement. Connection to the APC is through the parallel bus. For positioning there is a 32 bit hardware counter. • 1 digital input for synchronisation • 1 pulse encoder input • 2 analogue outputs

Communication Various communication boards are available to provide communication links between the APC and overriding control systems.

AF100 Advant Fieldbus 100 is a high-speed serial bus, which is used for communication between APCs or between an APC and an overriding system such as ABB’s Advant Controller AC400-family. The bus administrator board CI626 (BA) is needed for controlling the bus when not using the Advant Controller AC450. The communication board YPK112A is used to connect the APC to the Advant Fieldbus 100.

UART Board YPK113A The UART board, YPK113A, is used to communicate with other overriding systems. Protocols for Siemens Simatic S5 and Allen Bradley DH are available together with SAMI protocol.

Technical Data Optional I/O Connections The technical data and dimensions are valid at the time of printing. We reserve the right to subsequent alterations. Extended/Remote I/O board YPQ110A

8 digital inputs Opto isolated inputs, control voltage 110 VAC/ 24 VDC. Hardware delay 2 ms. Digital filter time constants from 0.5 ms to 128 ms in 0.5 ms steps. Input impedance 3 kΩ for 24 VDC and 13 kΩ for 110 VAC. 8 digital outputs 6 relay outputs, normally open contacts. Max. voltage 230 VAC, max. current 2 A at 230 VAC, min. switching time 20 ms. 2 opto isolated transistor outputs. Max. voltage 60 V DC, max. current 100 mA, min. switching time 100 µs. 4 analogue inputs Differential inputs, resolution 12 bits+sign. Input ranges -10 to +10 V or -20 to +20 mA (0 to +10 V, 0 to +1 V and 0/4 to 20 mA by software scaling), input impedance is 400 kΩ. Accuracy ± 0.1 % at ± 10 V and ± 0.4 % at ± 1 V. Hardware filter time constant 5 ms. Digital filter time constants from 5 ms to 32 s in 1 ms steps. 2 analogue outputs Output voltage -10 to +10 V, output current -10 to +10 mA. Resolution 12 bits+sign, accuracy ± 0.1 %. 3 voltage reference +10 V voltage reference, accuracy ± 1 mV. outputs Max. load current 10 mA. -10 V voltage reference, accuracy ± 5 mV. Max. load current 10 mA. 5 mA current reference, accuracy ± 0.05 mA. Max. load resistance 1 kΩ. Extended, connection through parallel bus: max. 4 boards. Remote, connection through low speed serial bus: max. 8 nodes. Speed measurement board YPH107A 1 digital input for Control voltage 24 V AC/DC or 110 V AC/DC. synchronisation Input impedance 3 kΩ at 24 V and 13 kΩ at 110 V. Hardware delay 1 ms or 10 ms, software adjustable. 1 pulse encoder input 3 opto isolated channels (A, B and Z), differential or single ended tachometers. ± 13 mA current input or ± 24 V voltage input. Max. input frequency 300 kHz. 2 analogue outputs Output voltage ± 10 V, output current ± 10 mA. Resolution 12 bits, accuracy ± 1 %.