ABBDistributed busbar protection REB500 including line and transformer protection Product Guide

Distributed busbar protection REB500

including line and transformer protection

Main features • Low-impedance busbar protection

• Stub and T-zone protection

• High functional reliability due to two independent measurement criteria:

- stabilized differential current algorithm

- directional current comparison algorithm

• Phase-by-phase measurement

• Reduced CT performance requirements

• High through-fault stability even in case of

CT saturation

• Full solid-state busbar replica

• No switching of CT circuits

• Only one hardware version for

- 1 and 5 A rated currents

- all auxiliary supply voltages between

48 V DC and 250 V DC

- nominal frequencies of 50, 60 and

16.7 Hz

• Short tripping times independent of the

plant’s size or configuration

• Centralized layout: Installation of hardware

in one or several cubicles

• Distributed layout: Bay units distributed

and, in the case of location close to the

feeders, with short connections to CTs, isolators, circuit breakers, etc.

• Connections between bay units and central

unit by fiber-optic cables

- maximum permissible length 1200 m

- for distributed and centralized layout

• fiber-optic connections mean interferenceproof data transfer even close to HV power

cables

• Replacement of existing busbar protection

schemes can be accomplished without restrictions (centralized layout) in the case of

substation extensions e.g. by a mixture of

centralized and distributed layout

• Easily extensible

• User-friendly, PC-based human machine

interface (HMI)

• Fully numerical signal processing

• Comprehensive self-supervision

• Binary logic and timer in the bay unit

• Integrated event recording

• Integrated disturbance recording for power

system currents

• A minimum of spare parts needed due to

standardization and a low number of varying units

• Communication facilities for substation

monitoring and control systems via

IEC 61850-8-1, IEC 60870-5-103 and LON

• IEC 62439 standard redundant station bus

communication

• IEC 61850-9-2 LE process bus communication

• Cyber security to support

- User Access Management

- User Activity Logging

Options

• Breaker failure protection (also separately

operable without busbar protection)

• End fault protection

• Definite time overcurrent protection

• Breaker pole discrepancy

• Current and voltage release criteria

• Disturbance recording for power system

voltages

• Separate I0 measurement for impedancegrounded networks

• Communication with substation monitoring

and control system (IEC 61850-8-1 /

IEC 60870-5-103 / LON)

• Internal user-friendly human machine interface with display

• Redundant power supply for central units

and/or bay units

Additional

main features

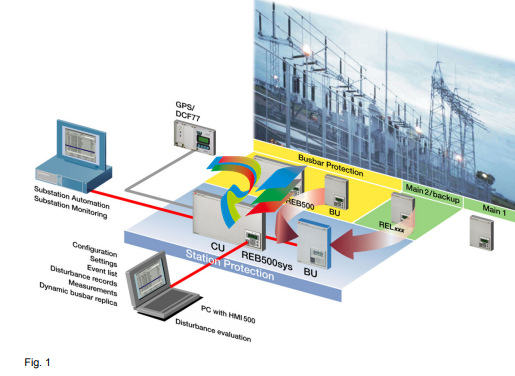

REB500sys combines the well-proven numerical busbar and breaker failure protection

REB500 of ABB with Main 2 or back-up protection for line or transformer feeders. The

Main 2 / Group 1 or back-up protection is

based on the well-proven protection function

library of ABB line and transformer protection

for 50, 60 and 16.7 Hz.

Main 2 / back-up bay protection

• Definite and inverse time over- and undercurrent protection

• Directional overcurrent definite and inverse

time protection

• Inverse time earth fault overcurrent protection

• Definite time over- and undervoltage protection

Distributed busbar protection REB500

including line and transformer protection

Page 3

• Three-phase current and three-phase voltage plausibility

Main 2 / back-up bay protection:

Line protection

• High-speed distance protection

• Directional sensitive earth fault protection

for grounded systems against high resistive faults in solidly grounded networks

• Directional sensitive earth fault protection

for ungrounded or compensated systems

• Autoreclosure for

- single-pole / three-pole reclosure

- up to four reclosure sequences

• Synchrocheck with

- measurement of amplitudes, phase

angles and frequency of two voltage

vectors

- checks for dead line, dead bus, dead

line and bus

Group 1 / back-up bay protection:

Transformer protection

• High-speed transformer differential protection for 2- and 3-winding and auto-transformers

• Thermal overload

• Peak value over- and undercurrent protection

• Peak value over- and undervoltage protection

• Overfluxing protection

• Rate of change frequency protection

• Frequency protection

• Independent T-Zone protection with transformer differential protection

• Power protection

Application REB500

The numerical busbar protection REB500 is

designed for the high-speed, selective protection of MV, HV and EHV busbar installations

at a nominal frequency of 50, 60 and 16.7 Hz.

The structure of both hardware and software

is modular enabling the protection to be easily

configured to suit the layout of the primary

system.

The flexibility of the system enables all configurations of busbars from single busbars to

quadruple busbars with transfer buses, ring

busbars and 1½ breaker schemes to be protected.

In 1½ breaker schemes the busbars and the

entire diameters, including Stub/T-Zone can

be protected. An integrated tripping scheme

allows to save external logics as well as wiring.

The capacity is sufficient for up to 60 feeders

(bay units) and a total of 32 busbar zones.

The numerical busbar protection REB500

detects all phase and earth faults in solidly

grounded and resistive-grounded power systems and phase faults in ungrounded systems

and systems with Petersen coils.

The main CTs supplying the currents to the

busbar protection have to fulfil only modest

performance requirements (see page 18). The

protection operates discriminatively for all

faults inside the zone of protection and

remains reliably stable for all faults outside the

zone of protection.

REB500sys

The REB500sys is foreseen in MV, HV and

EHV substations with nominal frequencies of

16.7, 50 Hz or 60 Hz to protect the busbars

and their feeders. The bay protection functions included in REB500sys are used as

Main 2 / Group 1 - or back-up protection.

The system REB500sys is foreseen for all single or double busbar configurations (Line variants L-V1 to L-V7 and Transformer variant TV1 to T-V4). In 1½ breaker configurations,

variant L-V5 can be used for the bay level

functions autoreclosure and synchrocheck.

The capacity is sufficient for up to 60 feeders

(bay units) and a total of 32 busbar zones.

The REB500sys detects all bus faults in solidly and low resistive-grounded power systems, all kind of phase faults in ungrounded

and compensated power systems as well as

feeder faults in solidly, low resistive-grounded,

compensated and ungrounded power systems.

The protection operates selectively for all

faults inside the zone of protection and

remains reliably stable for all faults outside the

zone of protection.

REB500sys is perfectly suited for retrofit concepts and stepwise upgrades. The bay unit is

used as a stand-alone unit for bay protection

functions (e.g. line protection, autoreclosure

and synchrocheck or 2- and 3 winding transformer protection or autonomous T-zone protection). The central unit can be added at a

later stage for full busbar and breaker failure

protection functionality.

Distributed busbar protection REB500

including line and transformer protection

Depending on the network voltage level and

the protection philosophy the following protection concepts are generally applied:

• Two main protection schemes per bay

and one busbar protection.

With REB500sys the protection concept

can be simplified. Due to the higher integration of functionality one of the main protection equipment can be eliminated.

• One main protection and one back-up

protection scheme per bay, no busbar

protection.

With REB500sys a higher availability of the

energy delivery can be reached, due to the

implementation of busbar and breaker failure protection schemes where it hasn't

been possible in the past because of economical reasons.

Nine standard options are defined for Main 2/

Group 1 or back-up bay level functions:

Line protection

- Line variant 1 (L-V1)

directional, non-directional overcurrent and

directional earth fault protection

- Line variant 2 (L-V2)

as line variant L-V1 plus distance prot.

- Line variant 3 (L-V3)

as line variant L-V2 plus autoreclosure

- Line variant 4 (L-V4)

as line variant L-V3 plus synchrocheck

- Line variant 5 (L-V5)

as line variant L-V1 plus autoreclosure and

synchrocheck.

- Line variant 6 (L-V6) for 16.7 Hz

non-directional overcurrent, distance protection, autoreclosure.

- Line variant 7 (L-V7) for 16.7 Hz

as line variant L-V6 plus directional earth

fault protection for grounded systems

Transformer protection

- Transformer variant 1 (T-V1)

2- or 3 winding transformer differential protection, thermal overload, current functions;

applicable also as autonomous T-zone protection.

- Transformer variant 2 (T-V2)

2-winding transformer differential protection, thermal overload, current functions,

overfluxing protection, neutral overcurrent

(EF).

- Transformer variant 3 (T-V3)

Distance protection for transformer back-up

or 2-winding transformer differential protection, thermal overload, current functions,

voltage functions, frequency functions,

power function, overfluxing protection.

- Transformer variant 4 (T-V4)

Transformer oriented functions/ back-up

functions -> thermal overload, current functions, voltage functions, frequency functions, power function, overfluxing protection.

Distributed busbar protection REB500

including line and transformer protection

Mode of

installation

There are three versions of installing the numerical busbar protection REB500 and the numerical station protection REB500sys:

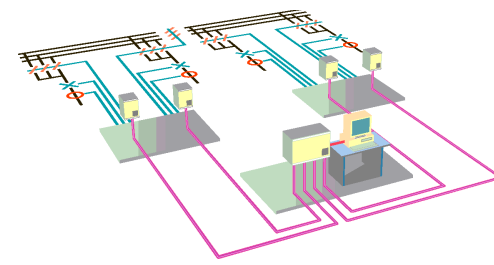

Distributed installation

In this case, the bay units (see Fig. 24) are

installed in casings or cubicles in the individual switchgear bays distributed around the

station and are connected to the central processing unit by optical fiber cables. The central processing unit is normally in a centrally

located cubicle or in the central relay room.

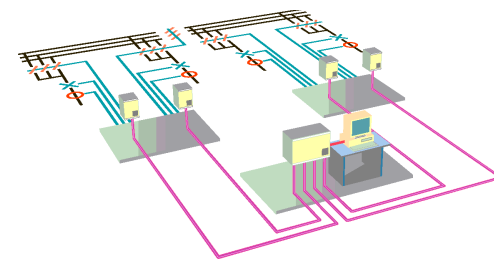

Centralized installation

19" mounting plates with up to three bay units

each, and the central processing unit are

mounted according to the size of the busbar

system in one or more cubicles (see Fig. 23).

A centralized installation is the ideal solution

for upgrading existing stations, since very

little additional wiring is required and compared with older kinds of busbar protection,

much more functionality can be packed into

the same space.

Combined centralized and distributed

installation

Basically, the only difference between a distributed and a centralized scheme is the

mounting location of the bay units and therefore it is possible to mix the two philosophies

Distributed busbar protection REB500

including line and transformer protection

Page 7

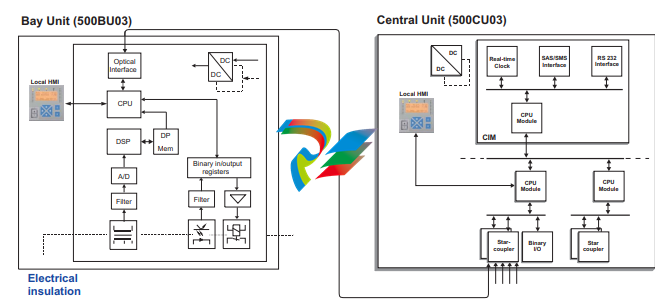

System design Bay unit (500BU03)

The bay unit (see Fig. 4) is the interface

between the protection and the primary system process comprising the main CTs, isolators and circuit-breaker and performs the

associated data acquisition, pre-processing,

control functions and bay level protection

functions. It also provides the electrical insulation between the primary system and the

internal electronics of the protection.

The input transformer module contains four

input CTs for measuring phase and neutral

currents with terminals for 1 A and 5 A. Additional interposing CTs are not required,

because any differences between the CT

ratios are compensated by appropriately configuring the software of the respective bay

units.

Optional input transformer module also contains five input voltage transformers for the

measurement of the three-phase voltages and

two busbar voltages and recording of voltage

disturbances or 6 current transformers for

transformer differential protection. (see

Fig. 12).

In the analog input and processing module,

the analog current and voltage signals are

converted to numerical signals at a sampling

rate of 48 samples per period and then

numerically preprocessed and filtered accordingly. Zero-sequence voltage and zero-current

signals are also calculated internally. The Process data are transferred at regular intervals

from the bay units to the central processing

unit via the process bus.

Every bay unit has 20 binary inputs and 16

relay outputs. The binary I/O module detects

and processes the positions of isolators and

couplers, blocking signals, starting signals,

external resetting signals, etc. The binary

input channels operate according to a patented pulse modulation principle in a nominal

range of 48 to 250 V DC. The PC-based HMI

program provides settings for the threshold

voltage of the binary inputs. All the binary output channels are equipped with fast operating

relays and can be used for either signaling or

tripping purposes (see contact data in Table

8).

A software logic enables the input and output

channels to be assigned to the various functions. A time stamp is attached to all the data

such as currents, voltages, binary inputs,

events and diagnostic information acquired by

a bay unit.

Where more binary and analog inputs are

needed, several bay units can be combined to

form a feeder/bus coupler bay (e.g. a bus coupler bay with CTs on both sides of the bus-tie

breaker requires two bay units).

The bay unit is provided with local intelligence

and performs local protection (e.g. breaker

failure, end fault, breaker pole discrepancy),

bay protection (Main 2 or back-up bay protections) as well as the event and disturbance

recording.

Distributed busbar protection REB500

including line and transformer protection

In the event that the central unit is out of operation or the optical fiber communication is disrupted an alarm is generated, the bay unit will

continue to operate, and all local and bay protection as well as the recorders (event and

disturbance) will remain fully functional

(stand-alone operation).

The hardware structure is based on a closed,

monolithic casing and presented in two

mounting solutions:

• Without local HMI: ideal solution if convenient access to all information via the central unit or by an existing substation

automation system is sufficient.

• With local HMI and 20 programmable LEDs

(Fig. 5): ideal solution for distributed and

kiosk mounting (AIS), since all information

is available in the bay.

For the latter option it is possible to have the

HMI either built in or connected via a flexible

cable to a fixed mounting position (see

Fig. 28).

In the event of a failure, a bay unit can be easily replaced. The replacement of a bay unit

can be handled in a simple way. During system start-up the new bay unit requests its

address, this can be entered directly via its

local HMI. The necessary setting values and

configuration data are then downloaded automatically.

Additional plug-and-play functionality

Bay units can be added to an existing

REB500 system in a simple way.

Fig. 5 Bay unit

Central unit (500CU03)

The hardware structure is based on standard

racks and only a few different module types

for the central unit (see Fig. 4).

The modules actually installed in a particular

protection scheme depend on the size, complexity and functionality of the busbar system.

A parallel bus on a front-plate motherboard

establishes the interconnections between the

modules in a rack. The modules are inserted

from the rear.

The central unit is the system manager, i.e. it

configures the system, contains the busbar

replica, assigns bays within the system, manages the sets of operating parameters, acts as

process bus controller, assures synchronization of the system and controls communication with the station control system.

The variables for the busbar protection function are derived dynamically from the process

data provided by the bay units.

The process data are transferred to the central processor via a star coupler module. Up to

10 bay units can be connected to the first central processor and 10 to the others. Central

processors and star coupler modules are

added for protection systems that include

more than 10 bay units. In the case of more

than 30 bay units, additional casings are

required for accommodating the additional

central processors and star coupler modules

required.

All modules of the central unit have a plugand-play functionality in order to minimize

module configuration.

One or two binary I/O modules can be connected to a central processing unit.

The central unit comprises a local HMI with 20

programmable LEDs (Fig. 6), a TCP/IP port

for very fast HMI500 connection within the

local area network.

Distributed busbar protection REB500

including line and transformer protection

Page 9

Functionality Busbar protection

The protection algorithms are based on two

well-proven measuring principles which have

been applied successfully in earlier ABB lowimpedance busbar protection systems:

• a stabilized differential current measurement

• the determination of the phase relationship

between the feeder currents (phase comparison)

The algorithms process complex current vectors which are obtained by Fourier analysis

and only contain the fundamental frequency

component. Any DC component and harmonics are suppressed.

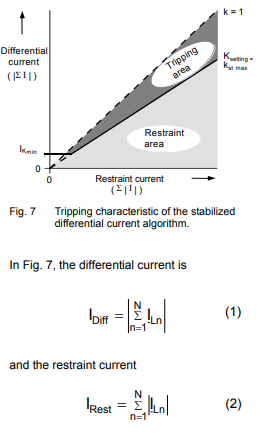

The first measuring principle uses a stabilized

differential current algorithm.

The currents are evaluated individually for

each of the phases and each section of busbar (protection zone).

where N is the number of feeders. The following two conditions have to be accomplished

for the detection of an internal fault:

where

kst stabilizing factor

kst max stabilization factor limit.

A typical value is kst max = 0.80

IK min differential current pick-up value

The above calculations and evaluations are

performed by the central unit.

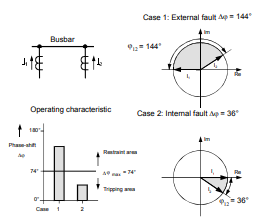

The second measuring principle determines

the direction of energy flow and involves comparing the phases of the currents of all the

feeders connected to a busbar section.

The fundamental frequency current phasors

1..n (5) are compared. In the case of an internal fault, all of the feeder currents have almost the same phase angle, while in normal

operation or during an external fault at least

one current is approximately 180° out of

phase with the others

The algorithm detects an internal fault when

the difference between the phase angles of all

the feeder currents lies within the tripping

angle of the phase comparator (see Fig. 8).

Distributed busbar protection REB500

including line and transformer protection

The task of processing the algorithms is

shared between the bay units and the central

processing unit. Each of the bay units continuously monitors the currents of its own fee-der,

preprocesses them accordingly and then filters the resulting data according to a Fourier

function. The analog data filtered in this way

are then transferred at regular intervals to the

central processing unit running the busbar

protection algorithms.

Depending on the phase-angle of the fault,

the tripping time varies at Idiff/Ikmin5 between 20 and 30 ms including the auxiliary

tripping relay.

Optionally, the tripping signal can be interlocked by a current or voltage release criteria

in the bay unit that enables tripping only when

a current above a certain minimum is flowing,

respectively the voltage is below a certain

value.

Breaker failure protection

The breaker failure functions in the bay units

monitor both phase currents and neutral current independently of the busbar protection.

They have two timers with individual settings.

Operation of the breaker failure function is

enabled either:

• internally by the busbar protection algorithm (and, if configured, also by the internal line protection, overcurrent or pole

discrepancy protection features) of the bay

level

• externally via a binary input, e.g. by the line

protection, transformer protection etc.

After the delay of the first timer has expired, a

tripping command can be applied to a second

tripping coil on the circuit-breaker and a

remote tripping signal transmitted to the station at the opposite end of the line.

This first timer operates in a stand-alone

mode in the bay unit.

If the fault still persists at the end of the second time delay, the breaker failure function

uses the busbar replica to trip all the other

feeders supplying the same section of busbar

via their bay units.

A remote tripping signal can be configured in

the software to be transmitted after the first or

second timer.

Phase-segregated measurements in each bay

unit cope with evolving faults.

End fault protection

In order to protect the “dead zone” between

an open circuit-breaker and the associated

CTs, a signal derived from the breaker position and the close command is applied.

The end fault protection is enabled a certain

time after the circuit-breaker has been opened. In the event of a short circuit in the dead

zone the nearest circuit-breakers are tripped.

This function is performed in a stand-alone

mode in the bay unit.

Overcurrent function

A definite time overcurrent back-up protection

scheme can be integrated in each bay unit.

(The operation of the function, if para-meterized, may start the local breaker failure protection scheme).

This function is performed in a stand-alone

mode in the bay unit.

Current release criteria

The current release criteria is only performed

in the bay unit. It is effective for a busbar protection trip and for an intertripping signal

(including end fault and breaker failure) and

prevents those feeders from being tripped that

are conducting currents lower than the setting

of the current release criteria.

Voltage release criteria

The voltage criterion is measured in the bay

unit. The function can be configured as

release criterion per zone through internal

linking in the central unit. This necessitates

the existence of one set of voltage transformers per zone in one of the bay units. Tripping

Distributed busbar protection REB500

including line and transformer protection

is only possible if the voltage falls short of

(U<) or exceeds (U0>) the set value.

Additionally this release criterion can be configured for each feeder (voltage transformers

must be installed). For details see Table 22.

Check zone criterion

The check zone algorithm can be used as a

release criterion for the zone-discriminating

low-impedance busbar protection system. It is

based on a stabilized differential current measurement, which only acquires the feeder currents of the complete busbar. The isolator /

breaker positions are not relevant for this criterion.

Neutral current detection I0

Earth fault currents in impedance-grounded

systems may be too low for the stabilized differential current and phase comparison functions to detect. A function for detecting the

neutral current is therefore also available, but

only for single phase-to-earth faults.

Pole discrepancy

A pole discrepancy protection algorithm

supervises that all three poles of a circuitbreakers open within a given time.

This function monitors the discrepancy between the three-phase currents of the circuitbreaker.

When it picks up, the function does not send

an intertripping signal to the central unit, but, if

configured, it starts the local breaker failure

protection (BFP logic 3).

This function is also performed in a standalone mode in the bay unit.

Event recording

The events are recorded in each bay unit. A

time stamp with a resolution of 1ms is attached to every binary event. Events are divided

into the three following groups:

• system events

• protection events

• test events

The events are stored locally in the bay unit or

in the central unit.

Disturbance recording

This function registers the currents and the

binary inputs and outputs in each bay. Voltages can also be optionally registered (see

Table 14).

A disturbance record can be triggered by

either the leading or lagging edges of all

binary signals or by events generated by the

internal protection algorithms. Up to 10 general-purpose binary inputs may be configured

to enable external signals to trigger a disturbance record. In addition, there is a binary

input in the central and the bay unit for starting

the disturbance recorders of all bay units.

The number of analog channels that can be

recorded, the sampling rate and the recording

period are given in Table 14. A lower sampling

rate enables a longer period to be recorded.

The total recording period can be divided into

a maximum of 15 recording intervals per bay

unit.

Each bay unit can record a maximum of 32

binary signals, 12 of which can be configured

as trigger signals.

The function can be configured to record the

pre-disturbance and post-disturbance states

of the signals.

The user can also determine whether the recorded data is retained or overwritten by the

next disturbance (FIFO = First In, First Out).

This function is performed in a stand-alone

mode in the bay unit (see page 7).

Note:

Stored disturbance data can be transferred via

the central unit to other computer systems for

evaluation by programs such as PSM505 [3].

Files are transferred in the COMTRADE format.

After retrieving the disturbance recorder data,

it is possible to display them graphically with

PSM505 directly.

Communication interface

Where the busbar protection has to communicate with a station automation system (SAS),

a communication module is added to the central unit. The module supports the interbay

bus protocols IEC 61850-8-1, IEC 60870-5-

103 and LON.

The IEC 61850-8-1 interbay bus transfers via

either optical or electrical connection:

• differential current of each protection zone

• monitoring information from REB500 central unit and bay units

• binary events (signals, trips and diagnostic)

• trip reset command

Distributed busbar protection REB500

including line and transformer protection

• disturbance recording data (via MMS file

transfer protocol)

• time synchronization with Simple Network

Time Protocol (SNTP)

• two independent time servers are supported. Server 2 as backup time

The LON interbay bus transfers via optical

connection:

• differential currents of each protection zone

• binary events (signals, trips and diagnostic)

• trip reset command

• disturbance recording data (via HMI500)

• time synchronization

The IEC 60870-5-103 interbay bus transfers

via either optical or electrical connection:

• time synchronization

• selected events listed in the public part

• all binary events assigned to a private part

• all binary events in the generic part

• trip reset command

Test generator

The HMI program (HMI500) which runs on a

PC connected to either a bay unit or the central processing unit includes a test generator.

During commissioning and system maintenance, the test generator function enables the

user to:

• activate binary input and output signals

• monitor system response.

• test the trip circuit up to and including the

circuit-breaker

• test the reclosure cycles

• establish and perform test sequences with

virtual currents and voltages for the bay

protection of the REB500sys

The test sequencer enables easy testing of

the bay protection without the need to decommission the busbar protection. Up to seven

se-quences per test stage can be started. The

sequences can be saved and reactivated for

future tests.

Isolator supervision

The isolator replica is a software feature without any mechanical switching elements. The

software replica logic determines dynamically

the boundaries of the protected busbar zones

(protection zones). The system monitors any

inconsistencies of the binary input circuits

connected to the isolator auxiliary contacts

and generates an alarm after a set time delay.

In the event of an isolator alarm, it is possible

to select the behavior of the busbar protection:

• blocked

• zone-selective blocked

• remain in operation

Differential current supervision

The differential current is permanently supervised. Any differential current triggers a timedelayed alarm. In the event of a differential

current alarm, it is possible to select the

behavior of the busbar protection:

• blocked

• zone-selective blocked

• remain in operation

Trip redirection

A binary input channel can be provided to

which the external signal monitoring the circuit-breaker air pressure is connected. Tripping is not possible without active signal.

When it is inactive, a trip generated by the

respective bay unit is automatically redirected

to the station at the opposite end of the line

and also to the intertripping logic to trip all the

circuit-breakers connected to the same section of busbar.

The trip redirection can also be configured

with a current criterion (current release criteria).

Distributed busbar protection REB500

including line and transformer protection

Page 13

Human machine interface (HMI)

The busbar protection is configured and maintained with the aid of human machine interfaces at three levels.

Local HMI

The local display interface installed in the central unit and in the bay units comprises:

• a four-line LCD with 16 characters each for

displaying system data and error messages

• keys for entering and display as well as 3

LEDs for the display of trips, alarms and

normal operation.

• in addition 20 freely programmable LEDs

for user-specific displays on the bay unit

500BU03 and central unit 500CU03.

The following information can be displayed:

• measured input currents and voltages

• measured differential currents (for the busbar protection)

• system status, alarms

• switchgear and isolator positions (within

the busbar protection function)

• starting and tripping signals of protection

functions

External HMI (HMI500)

More comprehensive and convenient control

is provided by the external HMI software running on a PC connected to an optical interface

on the front of either the central unit or a bay

unit. The optical interface is completely

immune to electrical interference. The PC

software facilitates configuration of the entire

busbar protection, the set-ting of parameters

and full functional checking and testing. The

HMI500 can also be operated via the LON

Bus on MicroSCADA for example, thus eliminating a separate serial connection to the central unit.

The HMI runs under MS WINDOWS NT, WINDOWS 98, WINDOWS 2000 and WINDOWS

XP. The HMI500 is equipped with a comfortable on-line help function. A data base comparison function enables a detailed

comparison between two configuration files

(e.g. between the PC and the central unit or

between two files on the PC).

Remote HMI

A second serial interface at the rear of the

central unit provides facility for connecting a

PC remotely via either an optical fiber, TCP/IP

or modem link. The operation and function of

HMI500 is the same whether the PC is connected locally or remotely.

Additional

functionalities

Bay level functions

These functions are based on the well established and well-proven functions built in the

ABB line and transformer protection. The bay

level functions contain all the relevant additional functions, which are normally requested

of a line and transformer protection scheme.

The line protection functions (L-V1 - L-V7) are

used as Main 2 or back-up for lines as well as

for transformer bays. The transformer protection functions (T-V1 - T-V4) are used as Group

2 or back-up bay protection for transformer

bays or as an independent T-Zone protection.

Distributed busbar protection REB500

including line and transformer protection

High-speed distance protection

• Overcurrent or underimpedance starters

with polygonal characteristic

• Five distance zones (polygon for forwards

and reverse measurement)

• Load-compensated measurement

• Definite time overcurrent back-up protection (short-zone protection)

• System logic

- switch-onto-fault

- overreach zone

• Voltage transformer circuit supervision

• Power swing blocking function

• HF teleprotection. The carrier-aided

schemes include:

- permissive underreaching transfer tripping

- permissive overreaching transfer tripping

- blocking scheme with echo and transient blocking functions

• Load-compensated measurement

- fixed reactance slope

- reactance slope dependent on load

value and direction (ZHV<)

• Parallel line compensation

• Phase-selective tripping for single and

three-pole autoreclosure

• Four independent, user-selectable setting

groups.

In the supervision mode the active and reactive power with the respective energy direction

is displayed by the HMI500.

Autoreclosure

The autoreclosure function permits up to four

three-phase autoreclosure cycles. The first

cycle can be single phase or three-phase.

If the REB500sys autoreclosure function is

employed, it can be used as a back-up for the

autoreclosure realized externally (separate

equipment or in the Main 1 protection).

When the autoreclosure function is realized

outside of REB500sys, all input and output

signals required by the external autoreclosure

equipment are available in order to guarantee

correct functionality.

Synchrocheck

The synchrocheck function determines the difference between the amplitudes, phase

angles and frequencies of two voltage vectors. The synchrocheck function also contains

checks for dead line and dead bus.

Transformer differential protection

• For two- and three-winding transformers

• Auto transformers

• Three-phase function

• Current-adaptive characteristic

• High stability for external faults and current

transformer saturation

• No auxiliary transformers necessary

because of vector group and CT ratio compensation

• Inrush restraint using 2nd harmonic

The transformer differential protection function

can also be used as an autonomous T-zone

protection in a 1½ breaker scheme.

Thermal overload

This function protects the insulation against

thermal stress. This protection function is normally equipped with two independently set

levels and is used when oil overtemperature

detectors are not installed.

Peak value over- and undercurrent protection

These functions are used for current monitoring with instantaneous response and where

insensitivity to frequency is required.

Peak value over- and undervoltage protection

This function is used for voltage monitoring

with instantaneous response and where insensitivity to frequency is required.

Frequency function

The function is used either as an over-/ underfrequency protection, or for load-shedding in

the event of an overload. Several stages of

the frequency protection are often needed.

This can be achieved by configuring the frequency function several times.

Rate of change frequency protection df/dt

This function is used for the static, dynamic

and adaptive load-shedding in power utilities

and industrial distribution systems. The function supervises the rate-of-change df/dt of one

voltage input channel. Several stages of the

rate-of-change frequency protection are often

Distributed busbar protection REB500

including line and transformer protection

Page 15

needed. This can be achieved by configuring

the rate-of-change frequency function several

times.

Definite time overfluxing protection

This function is primarily intended to protect

the iron cores of transformers against excessive flux. The function works with a definite

time delay. The magnetic flux is not measured

directly. Instead the voltage/frequency-ratio,

which is proportional to the flux is monitored.

Inverse time overfluxing protection

This function is primarily intended to protect

the iron cores of transformer against excessive flux. The function works with an inverse

time delay. The inverse curve ca be set by a

table of 10 values and the times t-min and tmax. The magnetic flux is not measured directly. Instead the voltage/frequency-ratio,

which is proportional to the flux is monitored.

Power function

This function provides single, or three phase

measurement of the real or apparent power.

The function can be configured for monitoring

reverse, active or reactive power (power

direction setting). Phase angle errors of the

CT/VT inputs can be compensated by setting.

The operating mode can be configured either

to underpower or to overpower protection.

Logics and delay/integrator

These functions allow the user the engineering of some easily programmable logical functions and are available as standard also in the

REB500 functionality.

Directional sensitive earth fault protection

for grounded systems

A sensitive directional ground fault function

based on the measurement of neutral current

and voltage is provided for the detection of

high-resistance ground faults in solidly or lowresistance grounded systems. The scheme

operates either in a permissive or blocking

mode and can be used in conjunction with an

inverse time earth fault overcurrent function.

In both cases the neutral current and voltage

can be derived either externally or internally.

This function works either with the same communication channel as the distance protection

scheme or with an independent channel.

Directional sensitive earth fault protection

for ungrounded or compensated systems

The sensitive earth fault protection function for

ungrounded systems and compensated systems with Petersen coils can be set for either

forwards or reverse measurement. The characteristic angle is set to ±90°

(U0 · I0 · sin ) in ungrounded systems and to

0° or 180° (U0 · I0 · cos ) for systems with

Petersen coils. The neutral current is always

used for measurement in the case of systems

with Petersen coils, but in ungrounded systems its use is determined by the value of the

capacitive current and measurement is performed by a measuring CT to achieve the

required sensitivity. To perform this function

the BU03 with 3I, 1MT and 5U is required.

Definite time over- and undercurrent protection

This function is used as Main 2 or as back-up

function respectively for line, transformer or

bus-tie bays. This function can be activated in

the phase- and/or the neutral current circuit.

Inverse time overcurrent protection

The operating time of the inverse time overcurrent function reduces as the fault current

increases and it can therefore achieve shorter

operating times for fault locations closer to the

source. Four different characteristics according to British Standard 142 designated normal

inverse, very inverse, extremely inverse and

long time inverse but with an extended setting

range are provided. The function can be configured for single phase measurement or a

combined three-phase measurement with

detection of the highest phase current.

Inverse time earth fault overcurrent protection

The inverse time earth fault overcurrent function monitors the neutral current of the system. Four different characteristics according

to British Standard 142 designated normal

inverse, very inverse, extremely inverse and

long time inverse but with an extended setting

range are provided.

Directional overcurrent definite / inverse

time protection

The directional overcurrent definite time function is available either with inverse time or definite time overcurrent characteristic. This

function comprises a voltage memory for

faults close to the relay location. The function

response after the memory time has elapsed

can be selected (trip or block).

Definite time over- and undervoltage protection

This function works with a definite time delay

with either single or three-phase measurement.

Distributed busbar protection REB500

including line and transformer protection

Additional functionalities (cont’d)

Three-phase current plausibility

This function is used for checking the sum and

the phase sequence of the three-phase currents.

Three-phase voltage plausibility

This function is used for checking the sum and

the phase sequence of the three-phase voltages.

Additional

features

Self-supervision

All the system functions are continuously

monitored to ensure the maximum reliability

and availability of the protection. In the event

of a failure, incorrect response or inconsistency, the corresponding action is taken to

establish a safe status, an alarm is given and

an event is registered for subsequent diagnostic analysis.

Important items of hardware (e.g. auxiliary

supplies, A/D converters and main and program memories) are subjected to various

tests when the system is switched on and also

during operation. A watchdog continuously

monitors the integrity of the software functions

and the exchange of data via the process bus

is also continuously supervised.

The processing of tripping commands is one

of the most important functions from the reliability and dependability point of view. Accordingly, every output channel comprises two

redundant commands, which have to be

enabled at regular intervals by a watchdog. If

the watchdog condition is not satisfied, the

channels are blocked.

Extension of the system

The system functions are determined by software, configured using the software configuration tool.

The system can be completely engineered in

advance to correspond to the final state of the

station. The software modules for new bays or

features can be activated using the HMI500

when the primary plant is installed or the features are needed.

Additional system functions, e.g. breaker failure, end fault protection or bay level

back-up / Main 2 functions can be easily activated at any time without extra hardware.

Resetting the trip commands/-signals

The following resetting modes can be selected for each binary output (tripping or signal

outputs):

• Latches until manually reset

• Resets automatically after a delay

Inspection/maintenance

A binary input is provided that excludes a bay

unit from evaluation by the protection system.

It is used while performing maintenance

respectively inspection activities on the primary equipment.

Redundant power supplies (Option)

Two power supply modules can be fitted in a

redundant arrangement, e.g. to facilitate

maintenance of station batteries. This is an

option for the central unit as well as for the

bay unit.

Time synchronization

The absolute time accuracy with respect to an

external time reference depends on the

method of synchronization used:

• no external time synchronization:

accuracy approx. 1 min. per month

• periodic time telegram with minute pulse

(radio or satellite clock or station control

system): accuracy typically ±10 ms

• periodic time telegram as above with second pulse: accuracy typically ±1 ms

• a direct connection of a GPS or DCF77 to

the central unit is possible: accuracy typically ±1 ms

• Furthermore, the time synchronization can

be done, if available, via the interbay bus

IEC103, LON or SNTP (in case IEC61850-

8-1 is used)

The system time may also be synchronized by

a minute pulse applied to a binary input on the

central unit.

Distributed busbar protection REB500

including line and transformer protection

Page 17

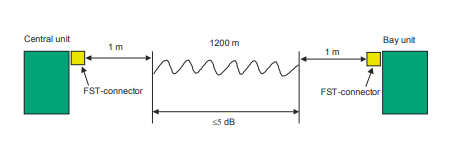

Requirements Optical fiber cables

A distributed busbar protection layout requires optical fiber cables and connectors with

the following characteristics:

• 2 optical fiber cores per bay unit

• glass fibers with gradient index

• diameter of core and sheath 62.5,

respectively 125 m

• maximum permissible attenuation 5 dB

• FST connector (for 62.5 m optical fibers)

• rodent protected and longitudinally waterproof if in cable ducts

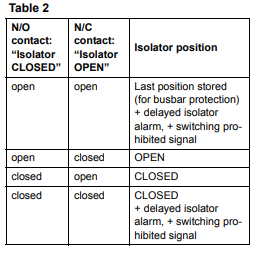

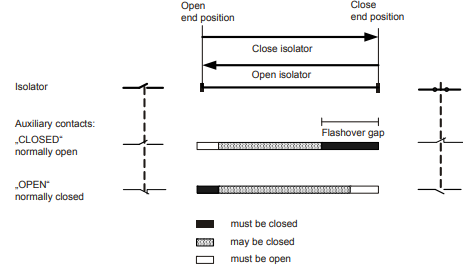

Isolator auxiliary contact

Auxiliary contacts on the isolators are connected to binary inputs on the bay units and

control the status of the busbar replica in the

numerical busbar protection.

One potentially-free N/O and N/C contact are

required on each isolator. The N/O contact

signals that the isolator is “CLOSED” and the

N/C contact that the isolator is “OPEN”. During the closing movement, the N/O contact

must close before the isolator main contact

gap reaches its flashover point.

Conversely, during the opening movement,

the N/O contact must not open before the isolator main contact gap exceeds its flashover

point.

If this is not the case, i.e. the contact signals

‘no longer closed’ beforehand, then the N/C

contact may not signal “OPEN” before the

flashover point has been exceeded.

Distributed busbar protection REB500

including line and transformer protection

Circuit-breaker replica

When the circuit-breaker replica is read in the

feeder or the bus-tie breaker, the circuitbreaker CLOSE command must also be connected.

Main current transformer

The algorithms and stabilization features used

make the busbar protection largely insensitive

to CT saturation phenomena. Main CTs types

TPS (B.S. class x), TPX, TPY, 5P.. or 10P.. are

permissible.

TPX, TPY and TPZ CTs may be mixed within

one substation in phase-fault schemes. The

relatively low CT performance needed for the

busbar protection makes it possible for it to

share protection cores with other protection

devices.

Current transformer requirements for stability during external faults (Busbar protection)

The minimum CT requirements for 3-phase

systems are determined by the maximum fault

current.

The effective accuracy limit factor (n') must be

checked to ensure the stability of the busbar

protection during external faults.

The rated accuracy limit factor is given by the

CT manufacturer. Taking account of the burden and the CT losses, the effective accuracy

limit factor n' becomes:

where:

n = rated accuracy limit factor

PN = rated CT power

PE = CT losses

PB = burden at rated current

In the case of schemes with phase-by-phase

measurement, n' must satisfy the following

two relationships:

where:

IKmax = max. primary through-fault current

I1N = rated primary CT current

Taking the DC time constant of the feeder into

account, the effective n' becomes:

(2) n' 10 for TN 120 ms, or

n' 20 for 120 ms <TN 300 ms.

where:

TN = DC time constant

Example: IKmax = 30000 A

I1N = 1000 A

TN 120 ms

Applying relationships (1) and (2):

(2) n' 10

Selected: n' 10

The current transformer requirements for

REB500sys for Line and Transformer protection are described in a separate publication

[1].

Pick-up for internal faults

In the case of internal busbar faults, CT saturation is less likely, because each CT only

conducts the current of its own feeder.

Should nevertheless CT saturation be possible, it is important to check that the minimum

fault current exceeds the setting for Ikmin.

Note:

For systems that measure I0, the REB500

questionnaire 1MRB520371-Ken should be

filled in and submitted to ABB, so that the CT

requirements can be checked in order to

ensure proper I0 measurement.