GEMotor Protection System Integrated process, control, and protection for low voltage motors

or generate an alarm when the voltage

drops below a specified voltage setting for

a programmable time delay.

Overvoltage

An overvoltage on running motor with a

constant load results in decreased current.

However, iron and copper losses increase,

causing an increase in motor temperature.

The current overload relay will not pickup

this condition and provide adequate

protection. The overvoltage element may

be used for protecting the motor in the

event of a sustaine overvoltage condition.

Contactor Failure

The MM2 monitors the contactor while

performing start and stop commands. If

the contactor does not change status an

‘open control circuit’ or ‘welded contactor’

alarm is triggered.

Additional Alarms

The MM2 has programmable alarms to

warn of a number of abnormal conditions.

These include: acceleration time exceeded,

abnormal inverter starter, incomplete start,

motor greasing, contactor inspection,

motor stop time, analog input, and process

interlock switch open.

Starters

MM2 can be programmed to serve as the

following types of motor starters:

• Full Voltage non-reversing,

• Full Voltage reversing,

• Wye/Delta open or close transition

starter,

• Two speed starter,

• Inverter (VSD) starter,

• Slip ring (rotor resistors) and primary

resistance starters,

• Autotransformer open or close

transition starter,

• Duty/Standby starter,

• Soft starter

Undervoltage Auto Restart

The motor can be automatically restarted

after a momentary power loss when this

feature is enabled. When the control

voltage drops below the dropout voltage

the contactors are de-energized. The MM2

can initiate timers to restart selected drives

upon the return of supply voltage. If control

voltage is restored within the programmed

restart time, the motor will be restarted

immediately. If the control voltage takes

longer to be restored, the MM2 can be

programmed to attempt a restart after a

programmed time delay.

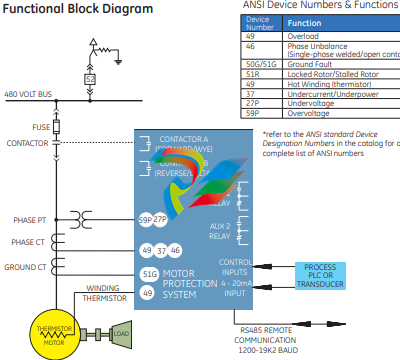

Outputs

The MM2 has one or two contactors (A

and B) which are used for motor starting.

There are also two auxiliary programmable

output relays available on the MM2,

which can be assigned to any one of 31

functions.

Switched Inputs

The MM2 has up to six fixed control inputs.

These are used for start A and B, stop, local

isolator, and contactor A and B status. The

MM2 also has up to 10 programmable

switch inputs. Each input can have one

of 33 interlock functions assigned to it. A

function can be assigned to one interlock

input only.

Analog Input

The analog input can be scaled to user

defined values. High and low alarm and trip

setpoints are recorded with time delays.

Monitoring and Metering

The MM2 offers advanced monitoring and

metering which includes:

Metering

The MM2 meters and displays:

• current of each phase

• Ground fault leakage current

• Motor load as a % of full load current

• Thermal capacity used (%)

• % Current unbalance

• Power (kW)

• Energy (kWh)

• Voltage

• Analog input

Trip Record

When the MM2 issues a trip command a

record is generated which includes the

cause and pre-trip actual values.

Statistics and Maintenance

The MM2 records statistical data about

relay and motor operation, allowing the

user to set the interval at which routine

maintenance tasks should be performed.

When the times are exceeded an alarm is

generated. These include:

• Motor greasing interval: number of

hours between bearing lubrication

• Contactor inspection: number of starts

after which the contactor contacts

must be inspected for wear

• Maximum motor stopped time: the

maximum number of hours the motor

can be left shut down

User Interfaces

When ordered with the Panel Mount

option, the MM2 comes equipped with a 40

character display, LED indicators, as well

programming and control push buttons.

Display and Keypad

The MM2 has a keypad and 40 character

display for local control and programming

without a computer. In the event of a

trip, alarm, or start block, the display will

automatically display a clear status

message.

In addition to the programming keys, the

panel mount option also provides 3 control

keys for starting and stopping the motor

locally.

Indicator LEDs

The panel mount MM2 has nine LED’s that

provide the status of the motor and relay

output contacts. Two additional LED’s

indicate whether the relay is in Auto or

Manual control mode.

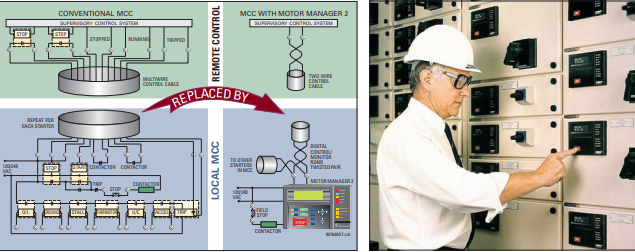

Communications

The MM2 uses a ModBus® RTU RS485

connection for communication. Up to 32

MM2s can be daisy-chained together on a

single communication channel. The MM2

supports a number of baud rates, ranging

from at 1200 to 19,200 bps. A RS232/485

converter module may be used to connect

a personal computer to the MM2.

Software

The MM2 comes with a Windows®-based

configuration program called MM2PC. It

allows access to all the features of the

MM2 with easy to use, pull-down menus.