NIOPERATING INSTRUCTIONS AND SPECIFICATIONS NI 9505

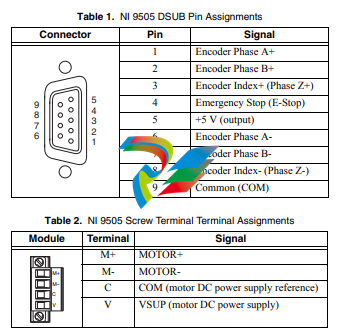

The NI 9505 also has a screw terminal connector that provides

connections to a motor DC power supply and a DC brushed servo

motor. Connect the positive lead of the power supply to terminal 4,

VSUP, and the negative lead to terminal 3, COM. Refer to Table 2

for the terminal assignments.

Note You must use 2-wire ferrules to create a secure

connection when connecting more than one wire to a

single terminal on the NI 9505 screw terminal.

Caution Do not turn on or plug in the motor DC power

supply until the screw terminal connector is fully inserted.

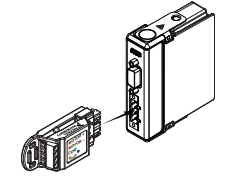

Optional Screw Terminal Accessory

Use the NI 9931 Screw Terminal Accessory instead of the

detachable screw terminal connector to increase the output power

of the module at temperatures below 70 ºC. The NI 9931 is

available from ni.com (NI part number 780571-01) or by calling

your National Instruments sales representative. Refer to the

Specifications section for more information. Refer to Figure 5 for

an illustration.

Figure 5. NI 9505 Module with Optional Screw Terminal Accessory

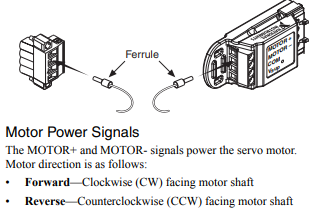

Wiring for High Vibration Applications

National Instruments recommends using ferrules to terminate

wires to the detachable screw terminal connector or the NI 9931

Screw Terminal Accessory when you use the NI 9505 in high

vibration applications. Refer to Figure 6 for an illustration.

Figure 6. 4-Terminal Screw Terminal Connector or

Accessory with a Ferrule

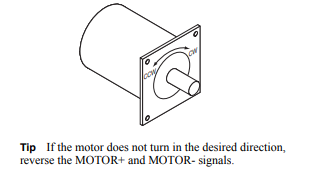

Motor Power Signals

The MOTOR+ and MOTOR- signals power the servo motor.

Motor direction is as follows:

• Forward—Clockwise (CW) facing motor shaft

• Reverse—Counterclockwise (CCW) facing motor shaf

Encoder Signals

The encoder signals consist of a Phase A, Phase B, and Index

(Phase Z) input. The NI 9505 supports differential and

single-ended inputs for Phase A, Phase B, and Index (Phase Z)

signals. Figures 8 and 9 show simplified schematic diagrams of the

encoder input circuit connected to differential and single-ended

inputs. You can also accommodate open-collector output encoders

by using a 1 kΩ pull-up resistor on each line to +5 VDC. Refer to

the Specifications section for more information about the encoder

inputs.

The encoder signals are raw digital input signals. These signals are

used in the LabVIEW FPGA Module for position and/or velocity

feedback. Figures 8 and 9 illustrate the use of the encoder signals

in a position and velocity loop in the LabVIEW FPGA Module.

Refer to the examples installed at labviewexamples

CompactRIOModule SpecificNI 9505 for examples of using

the encoder signals. Refer to the NI 9505 Reference Help book

in the LabVIEW Help, available by selecting Help»Search the

LabVIEW Help, for more information.

If the encoder cable length is greater than 3.05 m (10 ft), use

encoders with differential line driver outputs for your applications.

Power for a +5 V encoder—generated by a power supply inside the

NI 9505—is available on pin 5 of the DSUB connector.

Note The internal power supply is powered through the

Vsup pin.

Closed-loop servo applications require consistent directional

polarity between the motor and encoder for correct operation.

One industry-standard directional polarity is as follows:

• Positive = forward = clockwise (CW) facing motor shaft

• Negative = reverse = counterclockwise (CCW) facing motor

shaft

Refer to Figure 7 for a depiction of clockwise and

counterclockwise rotation. If encoder counting does not behave as

expected, change the encoder polarity in the FPGA or swap the

Phase A and Phase B connections.

When connecting the encoder wiring to the NI 9505, use shielded

wire of at least 24 AWG. You must use cables with twisted pairs

and an overall shield for improved noise immunity. Refer to

Figure 4 for a connection example.

Note Using an unshielded cable may produce noise,

which can corrupt the encoder signals and cause lost

counts, reduced accuracy, or other erroneous encoder and

drive operation.

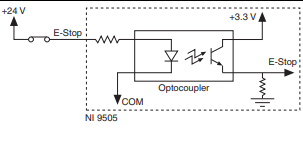

Emergency Stop Signal

The E-Stop signal is an input to the drive from an emergency stop

switch. Figure 10 shows a simplified schematic of the emergency

stop input circuit. When the emergency stop switch is closed,

current flows through the circuit, and the drive is enabled. When

an external event activates the emergency stop switch, the switch

opens and current stops flowing, disabling the drive. The E-Stop

functionality is disabled by default. Refer to the NI 9505 Reference

Help book in the LabVIEW Help, available by selecting Help»

Search the LabVIEW Help, for information about how to enable

this signal using the Enable E-Stop Property.

Figure 10. Emergency Stop Input Circuit

Cable Requirements for EMC Compliance

Use the following guidelines when selecting cables for the

NI 9505:

• Use shielded cables with a low impedance connection to

chassis ground to minimize noise and signal crosstalk.

• Tie the VSUP cable shield to chassis ground at the module side