ABBAC 800M PROFIBUS DP Configuration

NOTICE

This document contains information about one or more ABB products and may include a

description of or a reference to one or more standards that may be generally relevant to

the ABB products. The presence of any such description of a standard or reference to a

standard is not a representation that all of the ABB products referenced in this document

support all of the features of the described or referenced standard. In order to determine

the specific features supported by a particular ABB product, the reader should consult the

product specifications for the particular ABB product.

ABB may have one or more patents or pending patent applications protecting the intellectual property in the ABB products described in this document.

The information in this document is subject to change without notice and should not be

construed as a commitment by ABB. ABB assumes no responsibility for any errors that

may appear in this document.

In no event shall ABB be liable for direct, indirect, special, incidental or consequential

damages of any nature or kind arising from the use of this document, nor shall ABB be

liable for incidental or consequential damages arising from use of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written permission from ABB, and the contents thereof must not be imparted to a third party nor used

for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and

may be used, copied, or disclosed only in accordance with the terms of such license. This

product meets the requirements specified in EMC Directive 2004/108/EC and in Low Voltage Directive 2006/95/EC.

TRADEMARKS

All rights to copyrights, registered trademarks, and trademarks reside with their respective owners.

Copyright © 2003-2013 by ABB.

All rights reserved.

Release: December 2013

Document number: 3BDS009030-510 A

This user manual describes the configuration of the PROFIBUS DP-V1 in the

800xA control system using the communication interface CI854/CI854A.

The main areas covered in this user manual are:

• PROFIBUS functionalities available with CI854/CI854A,

• Hardware configuration with the Control Builder M,

• Supervision and status visualization of the PROFIBUS.

The reader of this manual is expected to have good knowledge of the 800xA control

system and the PROFIBUS in general.

This user manual is not the only source of instruction for PROFIBUS. ABB offers

training courses for those who use ABB control systems.

Any security measures described in this User Manual, for example, for user

access, password security, network security, firewalls, virus protection, etc.,

represent possible steps that a user of an 800xA System may want to consider

based on a risk assessment for a particular application and installation. This risk

assessment, as well as the proper implementation, configuration, installation,

operation, administration, and maintenance of all relevant security related

equipment, software, and procedures, are the responsibility of the user of the

800xA System.

This manual does not provide any information on the use and configuration of the

PROFIBUS bus communication interface module CI851. This information is

found in the online help of Control Builder M.

It also does not provide any information about installing the PROFIBUS network.

This information is provided in the AC 800M PROFIBUS DP Installation manual

(3BDS009029*) for PROFIBUS DP-V1.

Intended User

This manual is intended for application engineers and for engineers who are

planning the design of a PROFIBUS system. The reader should be familiar with

Control IT for AC 800M products and the programming tool, Control Builder M.

Also the reader should be familiar with the hardware and software functionality of

the 800xA system products. Apart from this, the user should have a good

PROFIBUS knowledge.

How to Use this User Manual

Section 1, Introduction gives a brief overview of PROFIBUS and how it is

integrated in the controllers.

Section 2, Functional Description provides detailed information on the PROFIBUS

implementation.

Section 3, Configuration describes the configuration of PROFIBUS with the Control

Builder M.

Section 4, Download and Online Mode describes the download procedure and the

system behavior in case of an error.

Section 5, Web Interface describes how to get detailed diagnostic information from

the system in case of a serious PROFIBUS error and how to set the slave address for

PA devices.

For a list of documentation related to the products described in this user manual, see

Released User Manuals and Release Notes on page 17.

User Manual Conventions

Microsoft Windows conventions are normally used for the standard presentation of

material when entering text, key sequences, prompts, messages, menu items, screen

elements, etc.

Warning, Caution, Information, and Tip Icons

This User Manual includes Warning, Caution, and Information where appropriate to

point out safety related or other important information. It also includes Tip to point

out useful hints to the reader. The corresponding symbols should be interpreted as

follows:

Although Warning hazards are related to personal injury, and Caution hazards are

associated with equipment or property damage, it should be understood that

operation of damaged equipment could, under certain operational conditions, result

in degraded process performance leading to personal injury or death. Therefore,

fully comply with all Warning and Caution notices.

Terminology

A complete and comprehensive list of Terms is included in the IndustrialIT

Extended Automation System 800xA, Engineering Concepts instruction

(3BDS100972*). The listing includes terms and definitions that apply to the 800xA

System where the usage is different from commonly accepted industry standard

definitions and definitions given in standard dictionaries such as Webster’s

Electrical warning icon indicates the presence of a hazard that could result in

electrical shock.

Warning icon indicates the presence of a hazard that could result in personal

injury.

Caution icon indicates important information or warning related to the concept

discussed in the text. It might indicate the presence of a hazard that could result

in corruption of software or damage to equipment/property.

Information icon alerts the reader to pertinent facts and conditions.

Tip icon indicates advice on, for example, how to design your project or how to

use a certain function

Released User Manuals and Release Notes

A complete list of all User Manuals and Release Notes applicable to System 800xA

is provided in System 800xA Released User Manuals and Release Notes

(3BUA000263*).

System 800xA Released User Manuals and Release Notes (3BUA000263*) is

updated each time a document is updated or a new document is released. It is in pdf

format and is provided in the following ways:

• Included on the documentation media provided with the system and published

to ABB SolutionsBank when released as part of a major or minor release,

Service Pack, Feature Pack, or System Revision.

• Published to ABB SolutionsBank when a User Manual or Release Note is

updated in between any of the release cycles listed in the first bullet.

For standards and commercially available PROFIBUS documentation please visit

the PROFIBUS Web Site (http://www.profibus.com).

A product bulletin is published each time System 800xA Released User Manuals

and Release Notes (3BUA000263*) is updated and published to ABB

SolutionsBank.

General Overview

PROFIBUS is a manufacturer-independent fieldbus standard for applications in

manufacturing, process and building automation. PROFIBUS technology is

described in fixed terms in DIN 19245 as a German standard and in EN 50170 / IEC

61158 as an international standard. The PROFIBUS standard is thus available to

every provider of automation product.

The PROFIBUS family is composed of three types of protocol, each of which is

used for different tasks. Of course, devices with all three protocols can communicate

with each other in a complex system by means of a PROFIBUS network.

The three types of protocols are: PROFIBUS FMS, DP and PA.

Only the two protocol types DP and PA are important for process automation.

PROFIBUS DP: the bus for the decentralized periphery

The PROFIBUS DP (RS 485) is responsible for communication between the

Controller level of a process automation system and the decentralized periphery in

the field, also intrinsic safety (RS485-IS) via DP-Ex barriers into hazardous area.

One feature of PROFIBUS DP is its high speed of transmission up to 12 Mbit/s.

PROFIBUS PA: extension for process automation

This PROFIBUS variant was developed for the process industry. Communication

and power supply to Transmitter and Positioners are handled direct via one 2-line

cable and correspond to IEC Standard 61158-2 (named also as MBP, MBP-LP).

Intrinsic safety (EEx i) (MBP-IS) installations in Zone 1 / Div.1 are possible.

Coupling components (Linking Devices) are used to integrate PA bus lines into the

PROFIBUS DP network. This ensures that all information is available in a

continuously connected network through the complete PROFIBUS system (DP and

PA).

The PROFIBUS DP is interfaced to the IEC61131 controller AC 800M using the

PROFIBUS DP-V1 module CI854/CI854A in the AC800M. For high availability

redundancy is supported.

The configuration for the PROFIBUS is done with the Control Builder M. The

configuration covers the planning of the HW units in the HW tree and the device

specific configuration for the master and slave units as well. The device specific

configuration data is described within the device specific GSD File provided by the

manufacturer of the device. To allow the configuration of the device within the

Control Builder M the GSD File has to be converted to a HWD File and inserted to

the project. The conversion is done with the GSD Import Tool.

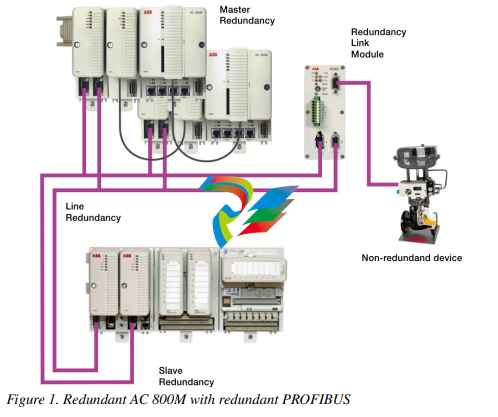

The following figure shows the redundant PROFIBUS connected to the redundant

AC 800M controller

Section 2 Functional Description

PROFIBUS Basics

Basic Functions DP-V0

Cyclic Data Communication

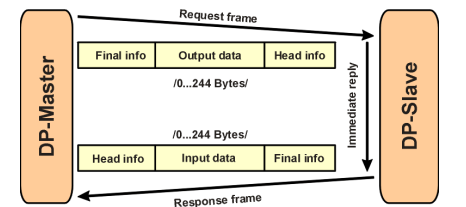

The data communication between the DPM1 (DP Master Class 1) and its assigned

slaves is automatically handled by the DPM1 in a defined, recurring sequence. With

each user data transfer, the master can write up to 244 bytes of output data to the

slave and read up to 244 bytes of input data from the slave. The Data is read and

written synchronously in one procedure

The assignment of the slaves to the DPM1, CI854/CI854A in this case, is done via

the HW configuration in Control Builder M.

The data communication between the DPM1 and the slaves is divided into three

phases: parameterization, configuration and data transfer. Before the master

includes a DP slave in the data transfer phase, a check is run during the

parameterization and configuration phase to ensure that the configured setpoint

configuration matches the actual device configuration. During this check, the device

type, format and length information and the number of inputs and outputs must also

correspond. This provides you with reliable protection against parameterization

errors.

Diagnostics

In addition to the cyclic data the PROFIBUS slave unit provides diagnostic data.

With this diagnostic data the slave can indicate errors or warnings on the slave unit,

the I/O-units or the I/O-channels. Some diagnostic data is generic and defined by the

PNO. But most of the diagnostic data is manufacturer specific.

The following errors/warnings are examples for PROFIBUS diagnostics:

Channel related:

– Wire break

– Short circuit

Module related:

– Wrong module type

– Module missing

Slave related:

– Power supply 2 error

– Internal bus error

The CI854/CI854A supports the operation of PROFIBUS DP-V0 diagnostics. The

diagnostic data transferred from the slave to the master is mapped by the

CI854/CI854A to the unit status of the PROFIBUS slave unit or the related I/O-unit

and is indicated as error or warning in the UnitStatus in Control Builder M for the

specific unit.

Only that diagnostic data configured within the hardware definition file is operated

by the system. The configuration includes

– Selection of diagnostic to be operated by the system.

– Mapping of the diagnostic information within the diagnostic frame on

PROFIBUS to the specific HW unit (slave or I/O unit).

– Definition of the corresponding bit in the unit status for the specific

diagnostic information. Use of device specific codes in

ErrorsAndWarnings and ExtendedStatus.

– Definition if the diagnostic information shall be indicated as error or

warning.

– Definition of the presented text within unit status and alarm/event for the

specific diagnostic information.

– Definition if in addition an alarm or event shall be generated for the

specific diagnostic information. If yes also the severity has to be defined.

For S800 I/O and S900 I/O the configuration for the diagnostics is already specified

in the hardware definition files that are provided with the system. For other slaves

the configuration for PROFIBUS diagnostics can be done via the DeviceImport

Wizard. The Device Import Wizard provides a dialog to pick up the diagnostic data

from the GSD-file and map it to the DeviceSpecific and ExtendedStatus bits of the

HwStatus for the related slave unit or I/O-unit. The dialog also supports the

configuration of alarms/events based on the diagnostic data. For more information

please refer to the online help for the GSD Import Tool.

DP Master Class 1 (DPM1) and Class 2 (DPM2)

TheDP master class 1 is the master that is in cyclic data transmission with the

assigned slaves. To get into the cyclic communication the DPM1 has to configure

the slave before.

The DP master class 2 is used for engineering and configuration. It does not have

cyclic data transmission with the slave devices. Normally a DPM2 is only connected

temporarily to the bus. A DPM2 can have class 2 communication to the slave

devices before the slaves are configured via DPM1 and cyclic communication is

active.

System Behavior

For a DPM1 master the following operating states are defined:

Stop

No data communication between the DPM1 and the slaves.

The CI854/CI854A is of type DP master class 1 (DPM1) and class 2 (DPM2).

Clear

The DPM1 reads the input information of the slaves and keeps the outputs of the

slavs in a fail-safe state (“0” output).

Operate

The DPM1 is in the data transfer phase. In cyclic data communication, inputs are

red from the slaves and output information written to the slaves.

The reaction of the system to a fault during the data transfer phase of the DPM1, for

example a failure of a slave, is determined by the “Auto Clear Modus” defined via

the BP flag configuration in the settings tab for CI854/CI854A. If this parameter is

enabled, the DPM1 switches the outputs of all assigned slaves to a fail-safe state the

moment a slave is no longer ready for user data transmission. The DPM1

subsequently switches to the clear state. If this parameter is disabled, the DPM1

retains in the operate state even in the event of a fault and the user can control the

reaction of the system. Please refer also to Settings Tab on page 49.

Sync and Freeze Mode

In addition to the normal cyclic communication between the DPM1 (DP Master

Class 1) and the assigned slaves, a master can send the control commands sync and

freeze via multicast to a group of slaves.

With the sync-command the addressed slaves will freeze the outputs in their current

state. New output values received by the master will be stored while the output

states remain unchanged. The stored output data are not sent to the outputs until the

next sync command is received. The Sync mode is terminated with the “unsync”

command.

In the same way, a freeze command causes the addressed slaves to enter freeze

mode. In this mode, the states of the inputs are frozen at their current value. The

input data are not updated again until the master sends the next freeze command.

Freeze mode is terminated with the “unfreeze” command.

The CI854/CI854A does not support sync and freeze mode

Monitoring the DP-V0 Communication

The cyclic communication between the DPM1 and the slaves is monitored by the

master and the slaves itself.

If the CI854/CI854A master unit detects a failure in the communication with a

slave, it will indicate the corresponding slave as disturbed. If enabled, Auto Clear

Modus will be activated. On CI854/CI854A a special handling is implemented to

support also redundancy for master and slave. In both cases the monitoring timings

consider the failovers of master and slave.

On slave side the communication with the master is controlled via the watchdog. If

no data communication with the master occurs within the watchdog control interval,

the slave automatically switches its outputs to the fail-safe state.

Please refer also to Connection Error on page 70

Multi Master Systems

In a multi master system several masters are connected to one bus. They represent

either independent subsystems, comprising one DPM1 (DP Master Class 1) and its

assigned slaves, or additional configuration and diagnosis devices. The

CI854/CI854A master unit supports multi master systems.

The Control Builder M with the integrated PROFIBUS master calculation does not

support multi master configurations. The calculation only covers one

CI854/CI854A with its assigned slaves. If you connect several CI854/CI854A or

additional configuration devices to the same bus you have to adapt the bus settings

manually. But only the TTR has to be adapted. An overall TTR has to be calculated

as the sum of all individual TTR for the CI854/CI854A master units connected to

the same PROFIBUS. The resulting TTR has to be manually configured for all

connected CI854/CI854A master units.

Example: you have three CI854/CI854A master units having the automatically

calculated TTR times 20.000, 30.000 and 40.000, then you have to manually

configure the TTR time 90.000 for all three units.

If a standalone tool is directly connected to the PROFIBUS as DPM2 (DP Master

Class 2) master for some acyclic communication, then the TTR time of this

master also has to be taken into account. Otherwise the standalone tool might get

communication problems

Acyclic Data Communication

The key feature of version DP-V1 is the extended function for acyclic data

communication. The acyclic data communication is mainly used for configuration

and parameterization purpose. With the acyclic DP-V1 read and write services the

master can read or write any desired data to and from the slave. The data is

addressed by slot, index and length. Each data block can be up to 244 bytes.

Figure 3. Acyclic Communication in DP-V1: Read Service

The transmission of acyclic data is executed in parallel to the cyclic data

communication, but with lower priority. Acyclic services are operated in the

remaining time at the end of the DP-V0 cycle.

The automatic master calculation for CI854/CI854A ensures that the gap on

PROFIBUS is big enough for some acyclic communication. If there is a need to

increase the gap for some additional acyclic communication this can be done via the

TTR time. Please refer also to Settings Tab on page 47.

Alarms and Status Messages

As a further function in DP-V1, the device specific diagnosis of the DP-V0 have

been enhanced and divided into the categories alarms and status messages. As the

major difference to the DP-V0 diagnosis, the alarms from the slave to the master are

transferred via confirmed services.

Redundancy

Overview

With PROFIBUS and CI854/CI854A you have a high scalability for redundancy.

You have the options to configure redundancy for:

• PROFIBUS master unit CI854A

• PROFIBUS slave unit

• PROFIBUS line.

Depending on your needs each type of redundancy can be configured independent

of each other. Also mixed configurations are supported. You can configure for

example a redundant PROFIBUS installation consisting of a redundant CI854A

master unit and redundant PROFIBUS lines and have connected redundant and nonredundant slave units in parallel.

A special mixture of redundancy is the so called combined slave and line

redundancy. A slave provides two slave units supporting the PNO slave redundancy

and each slave unit only provides one PROFIBUS interface. This is a one error

tolerant solution. The slave unit will only have communication on one PROFIBUS

line at a time and a single error on the PROFIBUS line will lead to a switchover of

the slave units. But the big advantage of this solution are the reduced cost. Therefore

it is a very popular solution. It is used for example for S800 I/O with CI840 and

S900 I/O with CI920.

Master Redundancy

The CI854A supports PROFIBUS master redundancy. Two CI854A connected to

one controller can be configured to work in a redundant configuration. The

configuration for redundancy is done via configuring the CI854A in the hardware

tree of the Project Explorer. For configuration of redundancy please refer to Add

Redundancy for Master Unit on page 41.

Primary and backup CI854A need different node addresses on PROFIBUS. While

the primary node address is configured via the settings in the HW Configuration

Editor the node address for the backup module is defined by the fixed offset -1 to the

node address of the primary module. Therefore you cannot configure the node

address 0 on PROFIBUS with CI854/CI854A. This is reserved for redundancy.

During normal operation only the primary CI854A has communication with the

slave units. The backup unit is in hotstandby mode. It is configured by the controller

and synchronized by the primary unit. If there is a failover because of for example a

disturbed PROFIBUS communication, primary and backup module change the node

addresses. During failover the former primary module will get reset.

After download and successful configuration the availability of the backup unit is

monitored. This includes the balancing of current data and the communication links

via PROFIBUS and CEX-Bus as well. In case of no error the DUAL LEDs on

primary and backup unit will be lit. If the backup unit is not ready to takeover the

DUAL LEDs will get off on both units. The error will be indicated in the unit status

and a potential redundancy switchover will be inhibited in this case.

Reasons to perform a switchover are for example that the primary unit has lost the

communication to all connected slaves “All slaves failed” because of for example a

cabling problems or a “Fatal error” on the primary CI854A itself was detected.

Slave Redundancy

The CI854/CI854A supports the PROFIBUS slave redundancy like specified by the

PROFIBUS User Organization (PNO). The specification can be found at

http://www.profibus.com.

A redundant slave has two PROFIBUS interfaces, one for the primary and one for

the backup slave. If line redundancy is used, one of the interfaces is connected to

line A and the other to line B. If not, both interfaces are connected to the same

PROFIBUS cable. The PROFIBUS address of the backup slave is always the

address of the primary slave plus 64. The configuration in the Control Builder

ensures, that both addresses are available when the slave is set redundant. If a

redundancy switchover of a slave occurs, also the PROFIBUS addresses are

switched. That means, the primary slave always has the assigned address and the

backup slave always has the address + 64 regardless of who is the primary and who

is the backup. This kind of redundancy is called "flying redundancy".

Only the primary slave can transfer process data and diagnostic information on the

PROFIBUS. Therefore the status of the primary slave also contains the information

of the backup slave. Please refer to the slave documentation for the details.

Although the backup slave has no active data transmission with the master the

CI854/CI854A is able to monitor the backup slave. The backup slave is available in

the Livelist and if redundancy is configured the monitoring will be activated. If the

backup slave fails, the information "Redundant slave does not exist" will be set in

the ExtendedStatus of the primary slave.

To allow the slave a failover in case of an error the CI854/CI854A has a special

monitoring function. If the redundant slave gets disturbed the CI854/CI854A waits

for (2* watchdog time + 1) before connection down will be indicated for the slave.

During this time the slave can perform a switchover and proceed with the normal

data exchange without interrupting the communication.

Line Redundancy

The CI854/CI854A supports line redundancy for PROFIBUS DP. Therefore the two

interfaces "PROFIBUS A" and "PROFIBUS B" are available on the baseplates

TP854 of the modules. There is a Redundancy Link Module functionality

implemented on the CI854/CI854A that handles the sending and receiving of data

on the PROFIBUS. Independent of any configuration the RLM sends data on both

lines and receives data only via one line. Regarding the receiving of data the RLM

checks if the slave sent data on both lines and if the data is valid. The first received

valid data on line A or B will be picked up and operated. It is possible that the slave

sends data on both lines in parallel or only on one line.

The monitoring of the line redundancy can be enabled or disabled. The default is

disabled. The enabling is done via the parameter "Line redundancy" in the settings

If the non-redundant slave gets disturbed the CI854/CI854A waits for watchdog

time before connection down will be indicated for the slave

for CI854/CI854A. If the line redundancy is enabled the warning "No activity on

PROFIBUS" will be indicated for the specific line in the case of a failure, for

example if there is a fault on the PROFIBUS cable.

Please enable the monitoring of line redundancy, if

– redundant slaves according to the PNO redundancy specification are used

and/or

– non-redundant slaves provide a line redundant interface and/or

– non-redundant slaves with only one PROFIBUS interface are connected to

the CI854/CI854A with a RLM01.

Status Handling

Status Handling for DP-V1 Master Unit

Every status information for CI854/CI854A in terms of hardware and software

errors is indicated via the unit status. The unit status is used to present the status of

the HW unit in Control Builder M while CBM is in online mode. In addition

alarms/events are generated based on the unit status (please refer also to Alarms and

Events on page 36). For special reasons also the access to the unit status via the

controller application is supported.