Technical Information Series 8 Controller and I/O Specification

1. Introduction

1.1. Overview

This document provides technical information to configure the Experion® Series 8 I/O and the C300 Controller.

1.2. Scope

The following Series 8 hardware items are included in this document.

Series 8 C300 Controller

Analog Input with HART – Differential

Analog Input with HART – Single Ended

Analog Input – Single Ended

Low Level Analog (Temperature) Input LLAI

Analog Output with HART

Analog Output

Digital Input, 24 VDC

Digital Input Sequence of Events (SOE)

Digital Input Pulse Accumulation

Digital Output, 24 VDC

DO Relay Extension Board

1.3. Definitions

Input Output Termination Assembly (IOTA): An assembly that holds the IOM and the connections for field wiring,

Input Output Module (IOM): A device that contains most of the electronics required to perform a specific I/O

function. The IOM plugs onto the IOTA.

2. Product Introduction

2.1. C300 Controller

2.1.1. Overview

The Experion C300 controller forms the heart of the Experion control system and deterministically executes control

strategies, batch operations, interfaces to local and remote I/O and directly hosts custom programmable applications. The

compact controller design does not require any additional Interface / communication modules and all control execution and

communications are contained in the controller module.

The C300 controller runs the filed proven, deterministic Control Execution Environment (CEE) which is the core C300

software that provides powerful and robust control for the distributed control system (DCS). The control strategies are

configured and loaded to the C300 controller through the Control Builder, an easy and intuitive engineering tool.

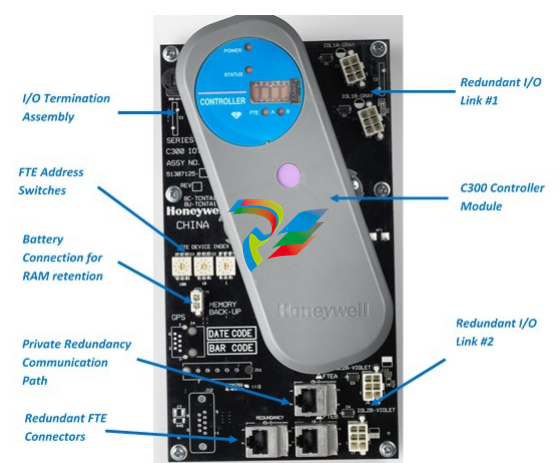

The C300 Controller is constructed using the Series 8 form factor that employs an Input Output Termination Assembly

(IOTA) and an electronics module which mounts and connects to the IOTA. One C300 Controller module and its IOTA

contains all of the control and communication functionalities. The C300 IOTA contains only passive devices such as

FTE address switches, FTE cable connectors and I/O Link cable connectors. Figure 1 below depicts the IOTA

components.

The C300 Controller may operate in both non-redundant and redundant configurations. Redundant operation require a

second identical controller with its own IOTA and connecting redundancy cable. The C300 Controller supports Series 8

I/O modules. Two IO Link interfaces, which are redundant, provide connection between the C300 controller and

associated I/O modules. The IO Link interface connectors are on the C300 IOTA

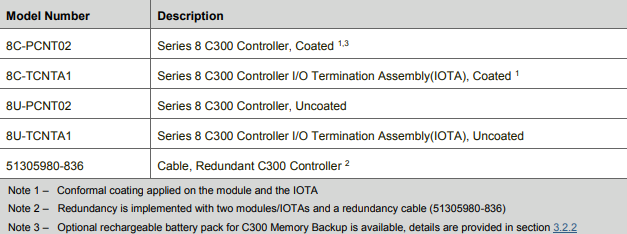

2.1.2. Model Numbers

The Model Numbers of C300 controller are shown as below

2.2. Series 8 I/O

2.2.1. Features

Series 8 features an innovative design that supports enhanced heat management. This unique look provides a significant

reduction in overall size for the equivalent function.

Both Series 8 IOM and IOTA are available in Coated and Uncoated variants. The term ‘Coated’ stands for hardware with

conformal coating material applied to electronic circuitry for protection against moisture, dust, chemicals, and temperature

extremes. Coated IOM and IOTA are recommended when electronics must withstand harsh environments and need to have

added protection.

For a quick reference, all the Series 8 Honeywell models starting with 8C denotes ‘with Conformal Coating’ and the models

starting with ‘8U’ denotes non-conformal coated hardware.

The unique features of the Series 8 I/O include:

I/O Module and field terminations are combined in the same area. The I/O Module is plugged into

the IOTA to eliminate the need for a separate chassis to hold the electronics assemblies

Two level “detachable” terminals for landing the field wiring in the enclosure, providing easier plant

installation and maintenance

Field power can be supplied through the IOTA, with no need for extra power supplies and the

associated craft wired marshalling

Redundancy is available directly on the IOTA without any external cabling or redundancy control

devices, by simply adding a second IOM to an IOTA

The innovative styling is one of its unique features. This styling includes features to facilitate the

effective use of control hardware in a systems environment. These features include:

o Vertical mounting for more effective wiring since most field wiring applications require entry from the

top or bottom of the systems cabinet

o An “information circle” for a quick visual cue to draw the Maintenance Technician’s eye to important

status information

o “Tilted” design for effective heat management within the cabinet enclosure. Since Series C allows for

a significant increase in cabinet density, an effective heat management system is critical for high

systems availability

o Input and output circuits are protected from shorts to alleviate the need for in-line fusing, reducing

installation and maintenance costs

Series 8 IOTAs combine multiple functions into a single piece of equipment:

o Single and redundant configurations

o On-board termination of process signals

o On-board signal conditioning

o On-board connection to appropriate networks (FTE, I/O LINK)

o Field power distribution without external marshalling

o IOM plugs into the IOTA and receives power from the IOTA

o The IOTA receives its power through cables from header board

2.2.2. I/O Module Functions

High Level Analog Input /HART Input Module (16pt) – The High Level Analog Input Module supports both

high level analog and HART inputs. Analog inputs are typically 4-20mA DC for both traditional and HART

devices. HART data can be used for status and configuration. HART data, such as the secondary and tertiary

variables, can also be used as process control variables. Two versions Single ended and Differential type are

available.

High Level Analog Input w/o HART (16pt) – The High Level Analog Input Module supports high level analog

inputs Analog inputs are typically 4-20mA DC for traditional devices.

Analog Output/HART Output Module (16pt) – The Analog Output Module supports both standard 4-20mA

DC outputs and HART transmitter outputs.

Analog Output w/o HART (16pt) – The Analog Output Module supports standard 4-20mA DC outputs.

Digital Input 24 VDC (32pt) – Digital input sensing for 24V signals

Digital Input Sequence of Events (32pt) – Accepts 24VDC discrete signals as discrete inputs. The inputs

can be time tagged to support 1ms resolution Sequence of Events.

Digital Input Pulse Accumulation (32pt) – Accepts 24VDC discrete signals as discrete inputs. The first

16 channels can be configured as Pulse accumulation to support Pulse Accumulation and frequency

measurement on per channel basis. Channels 17 – 32 can be configured as DI.

Digital Output 24 VDC (32pt) – Current sinking digital outputs. Outputs are electronically short-circuit

protected.

DO Relay Extension Board (32pt) – Digital output with NO or NC dry contacts. It can be used for low power

or high power applications.

Low Level Analog Input – RTD & TC (16pt) – Provides thermocouple (TC) and resistance temperature

device (RTD) inputs.

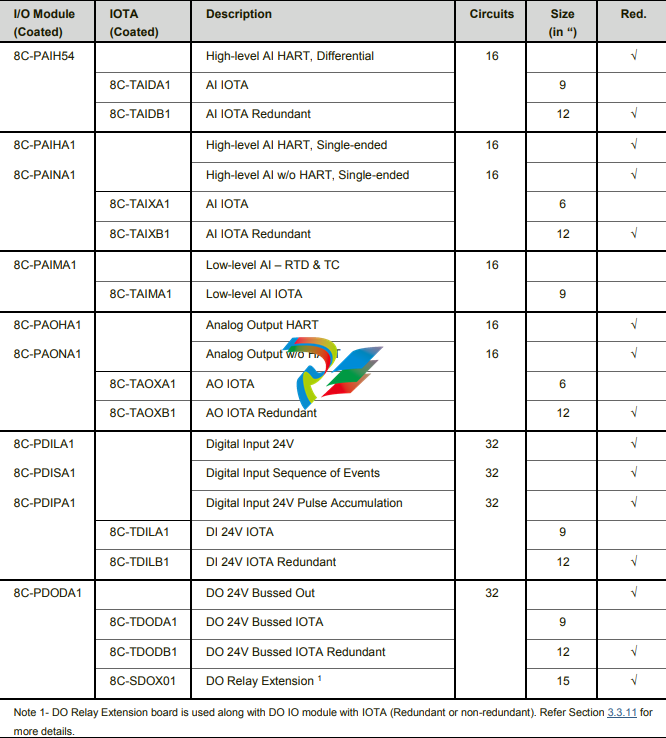

2.2.3. Series 8 I/O Sizing

In virtually all configurations, the C300 controller and Series 8 I/O provides useful, maintainable process equipment

connections in a smaller footprint than existing competitors and Honeywell equivalent products. Installing Series 8 I/O

modules contributes to overall total installed cost savings.

IOTA sizes vary based on the application. In general, an analog module has 16 points and resides on a 6 inch

(152mm) IOTA for non-redundant applications and a 12 inch (304mm) IOTA for redundant applications. A discrete

module has 32 points and resides on a 9-inch (228mm) IOTA for non-redundant applications and a 12 inch (304mm)

IOTA for redundant applications. Specific information on the size of a particular module is described in the Model

Number Table.

2.2.3.1. Series 8 Field connections

Series 8 Field connections use a standard modular connector. The connector modularity allows for removal and insertion of

the field wiring. This significantly reduces installation and maintenance procedures and can assist in field check out. Series 8

field connectors accept up to 12 AWG / 2.5 mm2 stranded wire.

2.2.3.2. I/O Module Sizes

IOTA Sizing is nominal (6in = 152mm, 9in =228mm, 12in =304mm). I/O modules are associated with their respective IOTAs

in the table below. The I/O Module is supported by one or more IOTAs. Below section also provides an overview of various

available IO modules, IOTA, IOTA size and redundancy features for Coated and Uncoated modules under separate tables.

Both Series 8 IOM and IOTA are available in Coated and Uncoated variants. The term ‘Coated’ stands for hardware with

conformal coating material applied to electronic circuitry for protection against moisture, dust, chemicals, and temperature

extremes. Coated IOM and IOTA are recommended when electronics must withstand harsh environments and need to have

added protection.

As a quick reference, all the Series 8 Honeywell models starting with 8C denotes ‘with Conformal Coating’ and the models

starting with ‘8U’ denotes non-conformal coated hardware.

3. Specifications

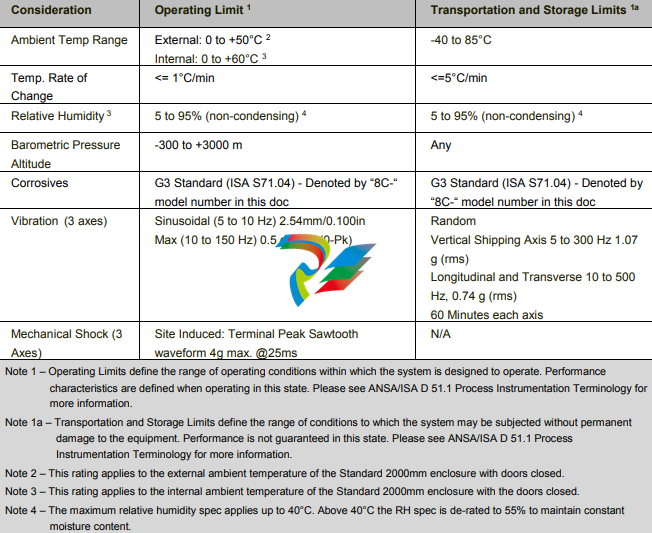

3.1. Environment Conditions and Approvals

3.1.1. General Environmental Characteristics and Series 8 Information

This section relates to the physical characteristics applicable to Series 8 C300 controller and all Series 8 I/O components.

Where applicable, specifications state limits within an approved cabinet and to the cabinet skin.

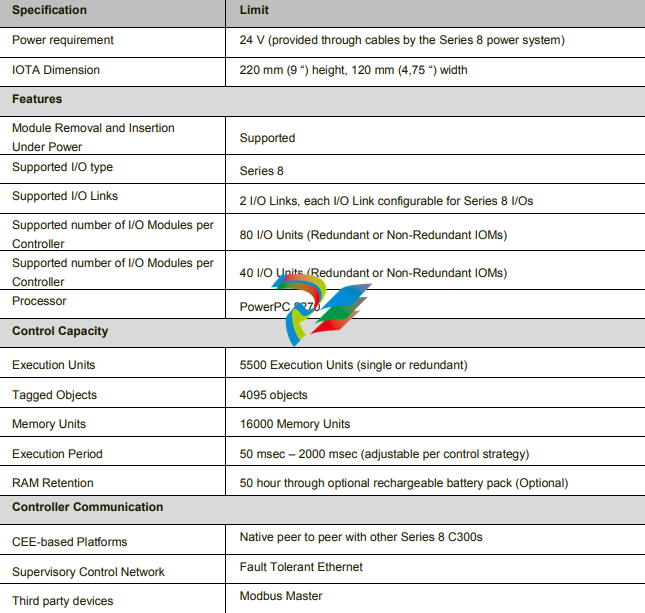

C300 Controller Specifications

3.2.1. C300 Control Execution Environment (CEE)

The C300 CEE provides an execution and scheduling environment in which Control Modules (CMs) and Sequential Control

Modules (SCMs) execute user-configured control strategies. The CEE also support peer to peer communications with other

C300 controllers and communication modules like Foundation Fieldbus and Profibus. The C300 CEE is configured using the

Control Builder Engineering environment. The Control builder provides a graphical engineering environment where

engineers can configure the Experion system and create control strategies by using the various function blocks available in

the Library. The C300 CEE based control strategies can be configured with minimum execution rates of 50 msec.

Specifications for Series 8 I/O

Specifications for Series 8 I/O modules are shown below. Note only the Coated S8 modules (model number starting with

8C) are mentioned in the detailed specifications below. However below specifications apply equally for the uncoated

modules as well. Refer section 2.2.3.2 for more details on uncoated Series 8 I/O model numbers.

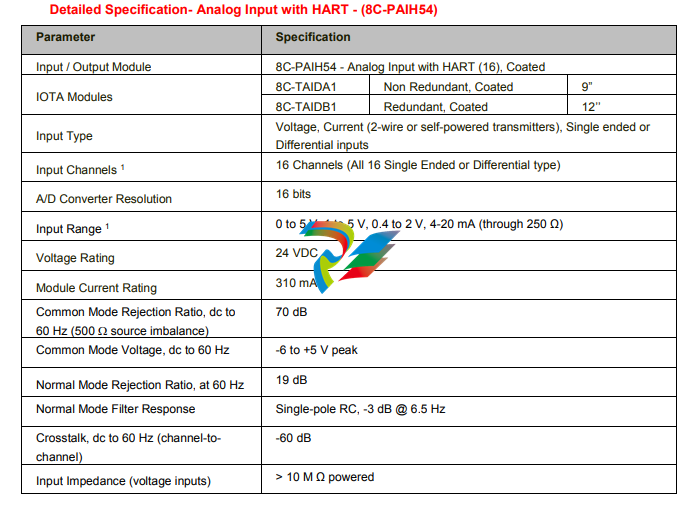

3.3.1. Analog Input with HART - Differential

Function

Analog Input Module accepts high level current or voltage inputs from transmitters and sensing devices.

Notable Features

Extensive self-diagnostics

Optional redundancy

Supports either Single Ended / Differential

Inputs

HART-capable, multivariable instruments and multiple

modems for fast collection of control variables

Fast loop scan