Technical Information Series 8 Controller and I/O Specification

1. Introduction

1.1. Overview

This document provides technical information to configure the Experion® Series 8 I/O and the C300 Controller.

1.2. Scope

The following Series 8 hardware items are included in this document.

Series 8 C300 Controller

Analog Input with HART – Differential

Analog Input with HART – Single Ended

Analog Input – Single Ended

Low Level Analog (Temperature) Input LLAI

Analog Output with HART

Analog Output

Digital Input, 24 VDC

Digital Input Sequence of Events (SOE)

Digital Input Pulse Accumulation

Digital Output, 24 VDC

DO Relay Extension Board

1.3. Definitions

Input Output Termination Assembly (IOTA): An assembly that holds the IOM and the connections for field wiring,

Input Output Module (IOM): A device that contains most of the electronics required to perform a specific I/O

function. The IOM plugs onto the IOTA.

2. Product Introduction

2.1. C300 Controller

2.1.1. Overview

The Experion C300 controller forms the heart of the Experion control system and deterministically executes control

strategies, batch operations, interfaces to local and remote I/O and directly hosts custom programmable applications. The

compact controller design does not require any additional Interface / communication modules and all control execution and

communications are contained in the controller module.

The C300 controller runs the filed proven, deterministic Control Execution Environment (CEE) which is the core C300

software that provides powerful and robust control for the distributed control system (DCS). The control strategies are

configured and loaded to the C300 controller through the Control Builder, an easy and intuitive engineering tool.

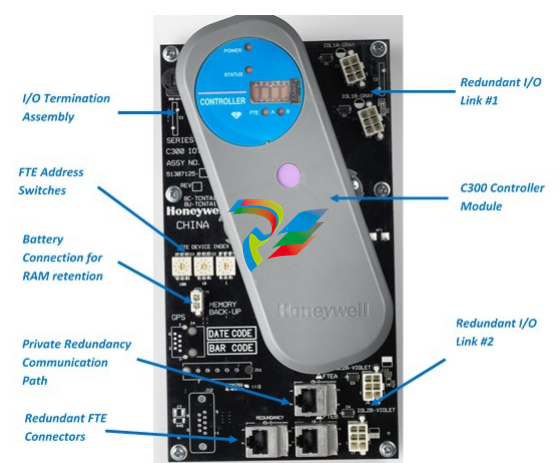

The C300 Controller is constructed using the Series 8 form factor that employs an Input Output Termination Assembly

(IOTA) and an electronics module which mounts and connects to the IOTA. One C300 Controller module and its IOTA

contains all of the control and communication functionalities. The C300 IOTA contains only passive devices such as

FTE address switches, FTE cable connectors and I/O Link cable connectors. Figure 1 below depicts the IOTA

components.

The C300 Controller may operate in both non-redundant and redundant configurations. Redundant operation require a

second identical controller with its own IOTA and connecting redundancy cable. The C300 Controller supports Series 8

I/O modules. Two IO Link interfaces, which are redundant, provide connection between the C300 controller and

associated I/O modules. The IO Link interface connectors are on the C300 IOTA

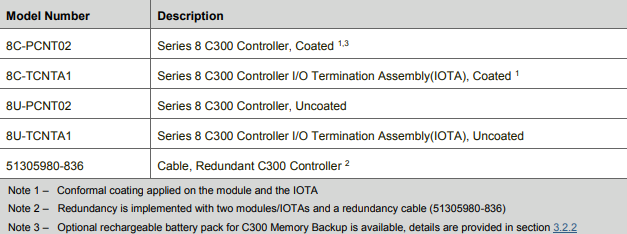

2.1.2. Model Numbers

The Model Numbers of C300 controller are shown as below

2.2. Series 8 I/O

2.2.1. Features

Series 8 features an innovative design that supports enhanced heat management. This unique look provides a significant

reduction in overall size for the equivalent function.

Both Series 8 IOM and IOTA are available in Coated and Uncoated variants. The term ‘Coated’ stands for hardware with

conformal coating material applied to electronic circuitry for protection against moisture, dust, chemicals, and temperature

extremes. Coated IOM and IOTA are recommended when electronics must withstand harsh environments and need to have

added protection.

For a quick reference, all the Series 8 Honeywell models starting with 8C denotes ‘with Conformal Coating’ and the models

starting with ‘8U’ denotes non-conformal coated hardware.

The unique features of the Series 8 I/O include:

I/O Module and field terminations are combined in the same area. The I/O Module is plugged into

the IOTA to eliminate the need for a separate chassis to hold the electronics assemblies

Two level “detachable” terminals for landing the field wiring in the enclosure, providing easier plant

installation and maintenance

Field power can be supplied through the IOTA, with no need for extra power supplies and the

associated craft wired marshalling

Redundancy is available directly on the IOTA without any external cabling or redundancy control

devices, by simply adding a second IOM to an IOTA

The innovative styling is one of its unique features. This styling includes features to facilitate the

effective use of control hardware in a systems environment. These features include:

o Vertical mounting for more effective wiring since most field wiring applications require entry from the

top or bottom of the systems cabinet

o An “information circle” for a quick visual cue to draw the Maintenance Technician’s eye to important

status information

o “Tilted” design for effective heat management within the cabinet enclosure. Since Series C allows for

a significant increase in cabinet density, an effective heat management system is critical for high

systems availability

o Input and output circuits are protected from shorts to alleviate the need for in-line fusing, reducing

installation and maintenance costs

Series 8 IOTAs combine multiple functions into a single piece of equipment:

o Single and redundant configurations