Technical Information Series 8 Controller and I/O Specification

o On-board termination of process signals

o On-board signal conditioning

o On-board connection to appropriate networks (FTE, I/O LINK)

o Field power distribution without external marshalling

o IOM plugs into the IOTA and receives power from the IOTA

o The IOTA receives its power through cables from header board

2.2.2. I/O Module Functions

High Level Analog Input /HART Input Module (16pt) – The High Level Analog Input Module supports both

high level analog and HART inputs. Analog inputs are typically 4-20mA DC for both traditional and HART

devices. HART data can be used for status and configuration. HART data, such as the secondary and tertiary

variables, can also be used as process control variables. Two versions Single ended and Differential type are

available.

High Level Analog Input w/o HART (16pt) – The High Level Analog Input Module supports high level analog

inputs Analog inputs are typically 4-20mA DC for traditional devices.

Analog Output/HART Output Module (16pt) – The Analog Output Module supports both standard 4-20mA

DC outputs and HART transmitter outputs.

Analog Output w/o HART (16pt) – The Analog Output Module supports standard 4-20mA DC outputs.

Digital Input 24 VDC (32pt) – Digital input sensing for 24V signals

Digital Input Sequence of Events (32pt) – Accepts 24VDC discrete signals as discrete inputs. The inputs

can be time tagged to support 1ms resolution Sequence of Events.

Digital Input Pulse Accumulation (32pt) – Accepts 24VDC discrete signals as discrete inputs. The first

16 channels can be configured as Pulse accumulation to support Pulse Accumulation and frequency

measurement on per channel basis. Channels 17 – 32 can be configured as DI.

Digital Output 24 VDC (32pt) – Current sinking digital outputs. Outputs are electronically short-circuit

protected.

DO Relay Extension Board (32pt) – Digital output with NO or NC dry contacts. It can be used for low power

or high power applications.

Low Level Analog Input – RTD & TC (16pt) – Provides thermocouple (TC) and resistance temperature

device (RTD) inputs.

2.2.3. Series 8 I/O Sizing

In virtually all configurations, the C300 controller and Series 8 I/O provides useful, maintainable process equipment

connections in a smaller footprint than existing competitors and Honeywell equivalent products. Installing Series 8 I/O

modules contributes to overall total installed cost savings.

IOTA sizes vary based on the application. In general, an analog module has 16 points and resides on a 6 inch

(152mm) IOTA for non-redundant applications and a 12 inch (304mm) IOTA for redundant applications. A discrete

module has 32 points and resides on a 9-inch (228mm) IOTA for non-redundant applications and a 12 inch (304mm)

IOTA for redundant applications. Specific information on the size of a particular module is described in the Model

Number Table.

2.2.3.1. Series 8 Field connections

Series 8 Field connections use a standard modular connector. The connector modularity allows for removal and insertion of

the field wiring. This significantly reduces installation and maintenance procedures and can assist in field check out. Series 8

field connectors accept up to 12 AWG / 2.5 mm2 stranded wire.

2.2.3.2. I/O Module Sizes

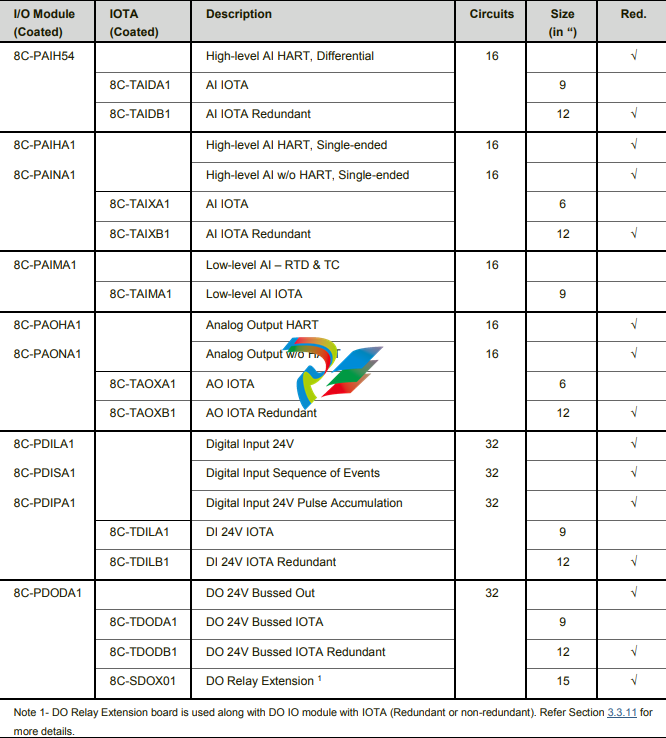

IOTA Sizing is nominal (6in = 152mm, 9in =228mm, 12in =304mm). I/O modules are associated with their respective IOTAs

in the table below. The I/O Module is supported by one or more IOTAs. Below section also provides an overview of various

available IO modules, IOTA, IOTA size and redundancy features for Coated and Uncoated modules under separate tables.

Both Series 8 IOM and IOTA are available in Coated and Uncoated variants. The term ‘Coated’ stands for hardware with

conformal coating material applied to electronic circuitry for protection against moisture, dust, chemicals, and temperature

extremes. Coated IOM and IOTA are recommended when electronics must withstand harsh environments and need to have

added protection.

As a quick reference, all the Series 8 Honeywell models starting with 8C denotes ‘with Conformal Coating’ and the models

starting with ‘8U’ denotes non-conformal coated hardware.

3. Specifications

3.1. Environment Conditions and Approvals

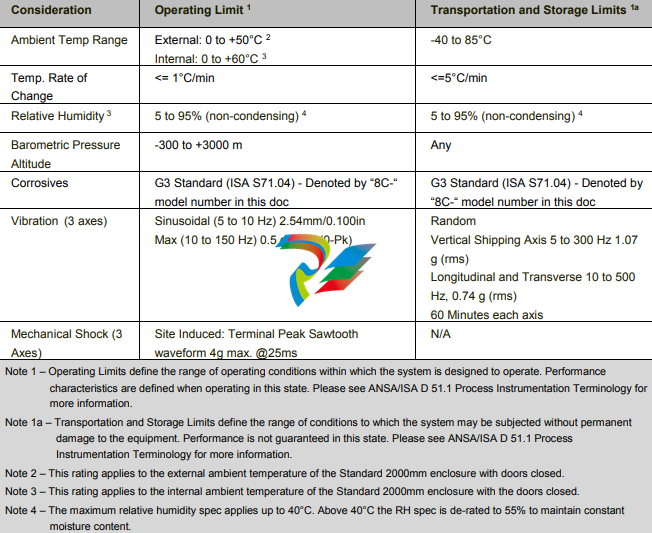

3.1.1. General Environmental Characteristics and Series 8 Information

This section relates to the physical characteristics applicable to Series 8 C300 controller and all Series 8 I/O components.

Where applicable, specifications state limits within an approved cabinet and to the cabinet skin.

C300 Controller Specifications

3.2.1. C300 Control Execution Environment (CEE)

The C300 CEE provides an execution and scheduling environment in which Control Modules (CMs) and Sequential Control

Modules (SCMs) execute user-configured control strategies. The CEE also support peer to peer communications with other

C300 controllers and communication modules like Foundation Fieldbus and Profibus. The C300 CEE is configured using the

Control Builder Engineering environment. The Control builder provides a graphical engineering environment where