HoneywellHC900 Process & Safety Controller User and Installation Manual

Notices and Trademarks

Copyright 2017 by Honeywell

Revision 6, 21 April 2017

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and

fitness for a particular purpose. Specifications may change without notice. The information we supply is believed

to be accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

This DANGER symbol indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This WARNING symbol indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury.

This CAUTION symbol may be present on Control Product instrumentation

and literature. If present on a product, the user must consult the

appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates a potentially hazardous situation, which, if

not avoided, may result in property damage.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

CAUTION, HOT SURFACE: This symbol warns the user of potential hot surfaces

which should be handled with appropriate caution.

Protective Earth (PE) terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national and local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

Functional Description

All Controllers

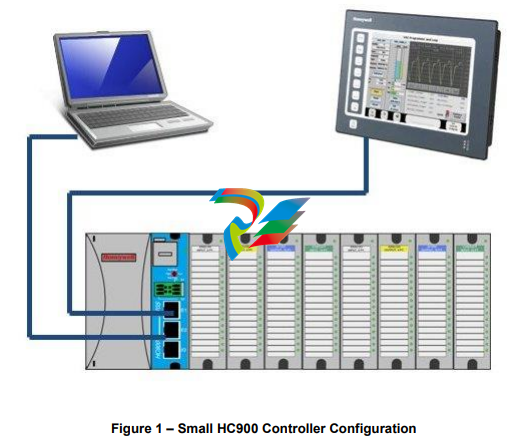

The Honeywell HC900 Process Controller is an integrated loop and logic controller that is designed specifically for

small-and medium-scale unit operations

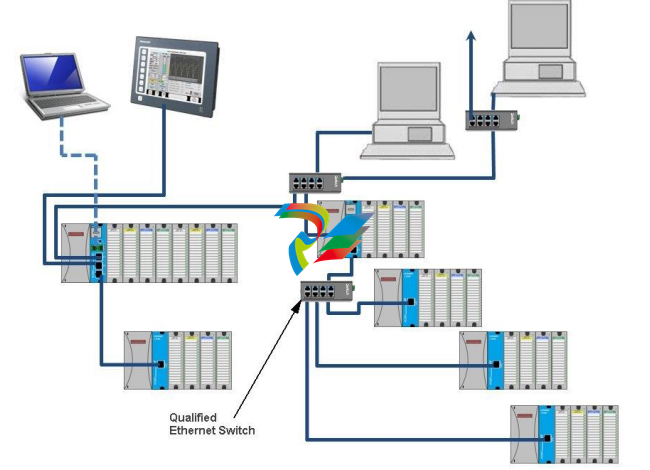

It comprises a set of hardware and software modules that can be assembled to satisfy any of a broad range of process

control applications. The HC900 Process Controller can consist of a single rack, as indicated in Figure 1, or can be

can be networked with other controllers via Ethernet links to expand the dimensions of control over a wider range of

unit processes, as indicated in Figure 2.

Although the HC900 E1/E2 ports provide protection against Cyber-security/DOS type attacks, additional protection

is required for safety applications using a firewall device configured to prevent uncontrolled messages into the

controller. Please refer to Ethernet Devices/Considerations Section in this manual for further information. The

figures in this manual assume the firewall is installed properly above the controller's Ethernet connection(s) E1 and

E2.

Figure 2 – Expanded HC900 Controller Configuration (C50/C70 CPU only)

The HC900 Controller design enables users and OEMs who are adept in system integration to assemble a system

that fits a broad range of requirements. Any configuration can be readily modified or expanded as requirements

dictate. In initial configuration and in subsequent modifications, the HC900 Controller affords an optimum balance

of performance and economy.

Configurations such as those shown in Figure 1 and in Figure 2, as well as many variations, can be assembled from

modular components. Many of the components are available from Honeywell, and some are available from thirdparty suppliers. These modular components are available in any quantity and mix that make the most sense for a

given application.

As indicated in Figure 3, the HC900 Controller includes provisions for communication via Ethernet with host

systems such as the Honeywell Experion HMI and other HMI software that supports Ethernet Modbus/TCP

protocol. Also, the communication structure of the HC900 Controller enables remote placement of input/output

.png)

.png)

.png)