HoneywellHC900 Process & Safety Controller User and Installation Manual

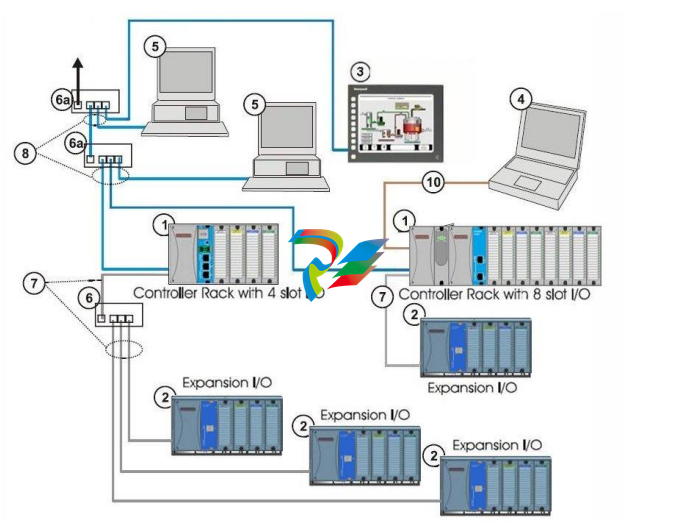

This illustration includes key-numbers that identify components that are described in Table 2

CAUTION

Communications lockout is possible in high network traffic conditions.

Extraneous traffic is possible when sharing bandwidth with other devices. We recommend putting the

controller on a private network segment. Failure to do so could, in high traffic cases, result in

communications lockout requiring the controller to be power-cycled.

Note: The HC900 is equipped with an Ethernet port as a standard feature (two Ethernet ports on the C70

& C75 CPU). These ports can function simultaneously as slave and master communications ports.

The dual Ethernet ports (C70 & C75 CPU’s) can be configured for redundant operation to a host.

If the host device does not have the inherent capability to recognize a network failover, the

Honeywell HWIOPC Server would be used to perform this functionality.

The dual Ethernet ports will not operate in a redundant configuration through a gateway to a

Host / server on another subnet. While both the E1 & E2 Ethernet can be configured with a default

Gateway address, only the E1 port will actually communicate across a gateway to another subnet

Hardware Components

This section contains general descriptions of each of the major components of the HC900 system.

For environmental specifications, refer to the section on Pre-Installation Planning.

HC900 Controller Rack

An HC900 Controller ("local rack") is shown in the following figure. As indicated in this figure, the Controller Rack

includes:

1. Rack, available in 4- 8-, or 12-slot versions

2. Power Supply

3. Controller Module

4. Grounding bars (for I/O wiring; optional)

5. Input/Output modules.

6. I/O Terminal Blocks

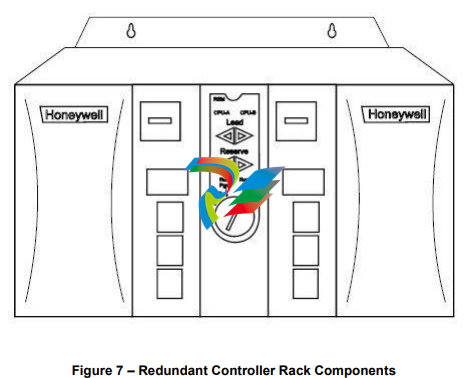

HC900 Redundant Controller Rack

A HC900 Redundant Controller is shown in the following figure.

1. Rack

2. Redundancy Switch Module (RSM) . Interface between Lead/Reserve controllers.

3. Lead/Reserve controllers. Two C75 CPUs, designated “CPU-A” (left), “CPU-B” (right).

4. Two 900P01-xxxx or 900P02-xxxx Power Supplies.