HoneywellControlEdge HC900 Controller Specifications 51-52-03-31, January 2022

Overview

The Honeywell ControlEdge HC900 Controller is an

advanced loop and logic controller offering a modular

design sized to satisfy the control and data management

needs of a wide range of process equipment. When

combined with the optional 900 Control Station operator

Interface that is highly integrated with the controller’s

database, configuration and setup time is minimized. This

powerful combination together with Honeywell’s

performance proven control technology provides users an

ideal solution for process control. Open Ethernet

connectivity with Modbus TCP Protocol also allows network

access using a variety of HMI/SCADA software. Program

execution environment is protected using an independent

watchdog timer.

Easy-to-use Windows-based Designer software, operable

over Ethernet or RS485 port (isolated) simplifies controller

configuration. The software is available in English, Chinese,

Russian, and German language version. It provides

advanced monitoring functions for debug, allows run-mode

process configuration changes while maintaining process

control, uploads the complete, annotated graphic controller

configuration, plus supplies an array of reports for

enhanced documentation. The ControlEdge HC900

Controller provides superior PID loop control and more

robust analog processing than most logic controllers without

compromising logic performance. A separate, fast scan

cycle executes a rich assortment of logic and calculation

function blocks. Logic blocks may also execute in the same

scan with analog function blocks for time critical events.

These function blocks may be fully integrated into a

combined analog and logic control strategy for

uncompromising control performance.

For more information see specification sheets:

• ControlEdge 900 Platform Modules

Specs 51-52-03-41

• Designer Software Specs 51-52-03-43

Applications

Mining & Metals Furnaces, Kilns, Boilers

Chemicals, Extruders Autoclaves

Pharmaceuticals Sterilizers, Dryers

Rail/ Infrastructure Burner Management,

HVAC/ DataCenters Combustion Control

Pulp & Paper Emergency Shutdown

Cement & Glass Pipeline Monitoring,

Power Spill Prevention

Features Summary

• Supports Split Rack Redundancy

• Supports Honeywell FDM (Field Device Manager)

using HART IP

• Supports HART function blocks (Command 3 and 48)

Note: UIO Module is required for HART support

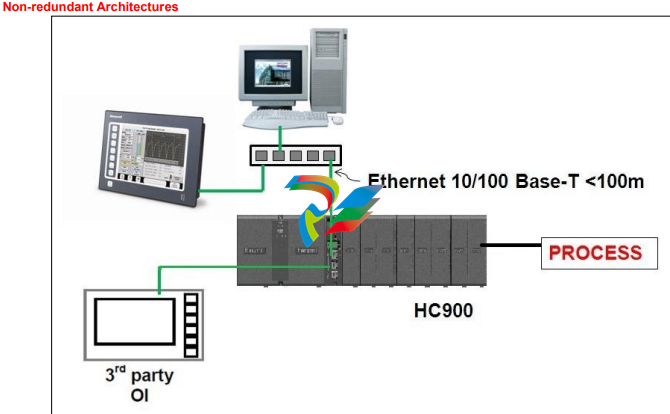

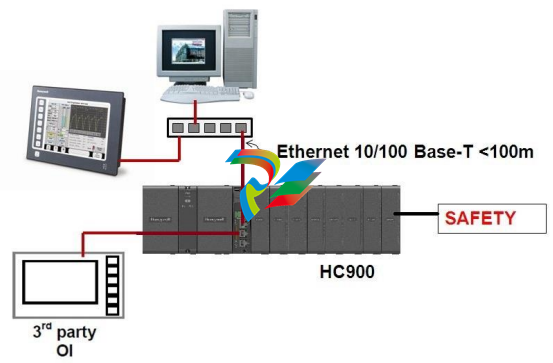

• Non-redundant and Redundant Architectures

• Sequence of events support (SOE)

Note: Supported only in non-redundant UIO

configuration.

• Redundant and Non-redundant Safety Universal IO

• PID Control with advanced Accutune III auto-tuning

• Safety peer communication between ControlEdge

HC900 controllers

• External watchdog timer with independent clocks

that detect spurious CPU lockups

• Adjustable recipe pool memory lets you allocate

memory for recipes, SP Profiles, sequences and

schedules to meet your needs

• Up to 4608 points with remote I/O

• Boolean Logic programming. Robust assortment of

over 100 algorithms

Features Summary, continued ..

• Advanced Floating Point Math Functions.

• Extensive alarm and event monitoring

• Up to 2304 galvanically Isolated, Analog Inputs

• Up to 1008 redundant UIO points

• New I/O voting and output validation function

blocks.

• Remote I/O Racks with wire for extended

distance.

• Star or Ring topology on IO network using

recommended switches

• Scanner and I/O Insert/Remove under power

• LED on/off indicators on digital I/O

• Graphic Function Block Configuration

• Open 10MB or 10/100MB Ethernet interface using

Modbus/TCP. Peer-to-peer communications via

Ethernet

• E-mail alarm/event messaging on priority

• Ramp/Soak Setpoint Programmers

• Setpoint Schedulers with multiple outputs

• Sequencers with 16 Outputs each

• Modbus read/write parameters assignable to either

fixed or custom addresses for access by HMI or

supervisory software.

• Modbus TCP Initiator

• Gas flow function blocks per American Gas

Association specs. (non-Safety configurations

only).

• Calendar block for triggering events

• Non-interfering process/safety worksheets capable

of handling process and safety configurations.

• Built in Version Control

• Fast updates - 10 ms digital and UIO (900U02-

xxxx) 100ms analog capable

Note: Low Level AI updates @ 0.5 sec.

ControlEdge HC900 Controller

• The rack based ControlEdge HC900 Controller is

available in 4 rack sizes with 1, 4, 8 or 12 I/O slots

each to support a wide range of requirements.

• Redundant C75 controllers use a separate controller

rack for CPUs without local I/O. Two power supplies

provide separate CPU power.

A redundant controller switch module provides status

and performs mode changes.

CPU Modules

• The CPU options available for the ControlEdge

HC900 Controller include:

▪ C30 and C50 for non-redundant applications.

▪ C70 for dual networking.

▪ C75 for redundant CPU applications and dual

networking.

▪ All ControlEdge HC900 CPU modules are based on the

.png)

.png)

.png)