HoneywellControlEdge HC900 Controller Specifications 51-52-03-31, January 2022

Overview

The Honeywell ControlEdge HC900 Controller is an

advanced loop and logic controller offering a modular

design sized to satisfy the control and data management

needs of a wide range of process equipment. When

combined with the optional 900 Control Station operator

Interface that is highly integrated with the controller’s

database, configuration and setup time is minimized. This

powerful combination together with Honeywell’s

performance proven control technology provides users an

ideal solution for process control. Open Ethernet

connectivity with Modbus TCP Protocol also allows network

access using a variety of HMI/SCADA software. Program

execution environment is protected using an independent

watchdog timer.

Easy-to-use Windows-based Designer software, operable

over Ethernet or RS485 port (isolated) simplifies controller

configuration. The software is available in English, Chinese,

Russian, and German language version. It provides

advanced monitoring functions for debug, allows run-mode

process configuration changes while maintaining process

control, uploads the complete, annotated graphic controller

configuration, plus supplies an array of reports for

enhanced documentation. The ControlEdge HC900

Controller provides superior PID loop control and more

robust analog processing than most logic controllers without

compromising logic performance. A separate, fast scan

cycle executes a rich assortment of logic and calculation

function blocks. Logic blocks may also execute in the same

scan with analog function blocks for time critical events.

These function blocks may be fully integrated into a

combined analog and logic control strategy for

uncompromising control performance.

For more information see specification sheets:

• ControlEdge 900 Platform Modules

Specs 51-52-03-41

• Designer Software Specs 51-52-03-43

Applications

Mining & Metals Furnaces, Kilns, Boilers

Chemicals, Extruders Autoclaves

Pharmaceuticals Sterilizers, Dryers

Rail/ Infrastructure Burner Management,

HVAC/ DataCenters Combustion Control

Pulp & Paper Emergency Shutdown

Cement & Glass Pipeline Monitoring,

Power Spill Prevention

Features Summary

• Supports Split Rack Redundancy

• Supports Honeywell FDM (Field Device Manager)

using HART IP

• Supports HART function blocks (Command 3 and 48)

Note: UIO Module is required for HART support

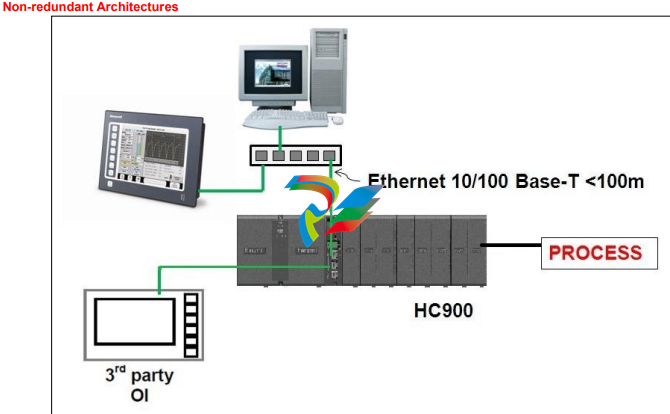

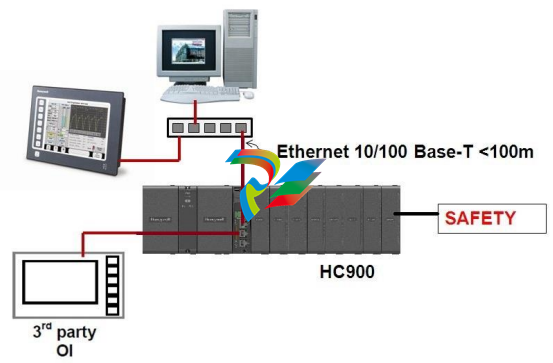

• Non-redundant and Redundant Architectures

• Sequence of events support (SOE)

Note: Supported only in non-redundant UIO

configuration.

• Redundant and Non-redundant Safety Universal IO

• PID Control with advanced Accutune III auto-tuning

• Safety peer communication between ControlEdge

HC900 controllers

• External watchdog timer with independent clocks

that detect spurious CPU lockups

• Adjustable recipe pool memory lets you allocate

memory for recipes, SP Profiles, sequences and

schedules to meet your needs

• Up to 4608 points with remote I/O

• Boolean Logic programming. Robust assortment of

over 100 algorithms

Features Summary, continued ..

• Advanced Floating Point Math Functions.

• Extensive alarm and event monitoring

• Up to 2304 galvanically Isolated, Analog Inputs

• Up to 1008 redundant UIO points

• New I/O voting and output validation function

blocks.

• Remote I/O Racks with wire for extended

distance.

• Star or Ring topology on IO network using

recommended switches

• Scanner and I/O Insert/Remove under power

• LED on/off indicators on digital I/O

• Graphic Function Block Configuration

• Open 10MB or 10/100MB Ethernet interface using

Modbus/TCP. Peer-to-peer communications via

Ethernet

• E-mail alarm/event messaging on priority

• Ramp/Soak Setpoint Programmers

• Setpoint Schedulers with multiple outputs

• Sequencers with 16 Outputs each

• Modbus read/write parameters assignable to either

fixed or custom addresses for access by HMI or

supervisory software.

• Modbus TCP Initiator

• Gas flow function blocks per American Gas

Association specs. (non-Safety configurations

only).

• Calendar block for triggering events

• Non-interfering process/safety worksheets capable

of handling process and safety configurations.

• Built in Version Control

• Fast updates - 10 ms digital and UIO (900U02-

xxxx) 100ms analog capable

Note: Low Level AI updates @ 0.5 sec.

ControlEdge HC900 Controller

• The rack based ControlEdge HC900 Controller is

available in 4 rack sizes with 1, 4, 8 or 12 I/O slots

each to support a wide range of requirements.

• Redundant C75 controllers use a separate controller

rack for CPUs without local I/O. Two power supplies

provide separate CPU power.

A redundant controller switch module provides status

and performs mode changes.

CPU Modules

• The CPU options available for the ControlEdge

HC900 Controller include:

▪ C30 and C50 for non-redundant applications.

▪ C70 for dual networking.

▪ C75 for redundant CPU applications and dual

networking.

▪ All ControlEdge HC900 CPU modules are based on the

e300 32 Bit RISC based PowerPC Architecture. The

controller operates out of a battery-backed DDR2 64MB

memory for C30 and C50 modules, 128MB for C70 and

C75 modules. DDR2 memory on all modules is

supported with ECC circuitry to enhance reliability and

error detection.

Program execution environment is protected using an

independent watchdog timer.

• All ControlEdge HC900 CPU modules offer open Ethernet

communications for access by a variety of HMI and

SCADA software applications and peer to peer

communications for control data exchanges between

controllers. The C70 and C75 provide dual Ethernet ports

for high network availability installations.

• ControlEdge HC900 CPU modules use a dual scan

method to handle fast digital scanning and normal analog

input scanning in the same integrated control

environment. Both scans support a wide range of

computational function block algorithms and a user

adjustable execution sequence order.

ControlEdge HC900 CPUs use Flash memory for

permanent user configuration program storage

and battery-backed memory for dynamic data

storage allowing for graceful recovery following a

power interruption or other discontinuous

operations. Using proven TL5903 primary

batteries to support up to 24 days of continuous

power outages

• 5000 SOE event buffering capability

I/O Scanners

ControlEdge HC900 Remote I/O is processed and

communicated to the main CPU module through a

remote I/O Scanner module. Two I/O scanner modules

are available: a single port model for non-redundant

CPU systems and a dual port model for redundant

CPU systems. Scanner addressing in multi-rack

systems is selectable via DIP switch setting.

Program execution environment is protected using an

independent watchdog timer.

Inputs and Outputs - A variety of I/O modules are

available for selection in creating a custom control

solution. These include:

• 8-point universal analog input modules: Inputs

may be mixed on a module and may include

multiple thermocouple types, RTDs, ohms,

voltage, current or millivoltage types – all easily

assigned using the Designer configuration tool.

High point-to-point isolation simplifies installation

and saves the expense of external isolation

hardware.

• 16-point high level analog input module: each

point is configurable for V or mA. Point-to-point

isolation.

• 4-point galvanically isolated analog output

module: Supports from 0 to 20mA each.

• 8-point analog output module. Galvanically

isolated in two groups of 4. Supports 0 to 20mA.

• 16-point (14-point for redundant configuration)

Universal I/O module galvanically isolated Input/

Output to chassis. Each point can configured as

DI, DO, AI or AO.

• 16-point digital galvanically isolated AC/DC input

module.

• 16-point analog output module. Galvanically isolated in

four groups of 4. Supports 0 to 20mA.

• 16-point digital galvanically isolated input modules:

Contact closure type, DC voltage and AC voltage types.

• 32-point galvanically isolated digital input (sink) module:

DC voltage

• 8-point AC or 16 point galvanically isolated DC digital

output (sink) modules

• 32-point galvanically isolated digital output (source): DC

voltage

• 8-point galvanically isolated high voltage

• 8-point galvanically isolated relay output module: four

form C type and four forms A type relays.

• 4 channel Pulse/ Frequency/Quadrature I/O module

See Module Specifucation sheet 51-52-03-41 for details.

Insert & removal of I/O under power - For ease of

maintenance, the ControlEdge HC900 controller supports

removing and inserting modules from the card rack without

removing power from the controller. Each card is sensed for

validity by the controller and auto-configured on insertion.

Hardware can be replaced without shutting down operations

for replacement of CPU or Scanner modules thus reducing

downtime and total cost of ownership.

I/O Terminal Blocks – 20-screw Terminal Blocks

are available with either barrier style or Euro style screw

connections. A module label area is provided for field wiring

identification. An available 36-screw Euro Terminal block is

required for certain high capacity modules.

Remote I/O - I/O racks may be remotely mounted

from the controller via a dedicated Ethernet 10/100Base-T

connection at up to 300 meters (984 feet) between the

controller and the most remote rack using two Ethernet

switches. Use of fiber optic cable extends distance to 40

Kilometers.

Remote Terminal Panels - Optional DIN rail mounted

Remote Terminal Panels (RTPs) are available for use

with pre-wired cables to reduce installation time and

labor expense. RTP types available: analog input,

relay output, discrete input, discrete output, analog

output.

Three cable lengths are also available to match

hardware to installation variations. See Module

Specification sheet 51-52-03-41 for more details.

Redundant Power - A second (backup) power module may

be added to each ControlEdge HC900 controller rack. An

extended rack is available that expands the standard 8 and

12 I/O rack to accommodate a second (redundant) power

supply and power status module.

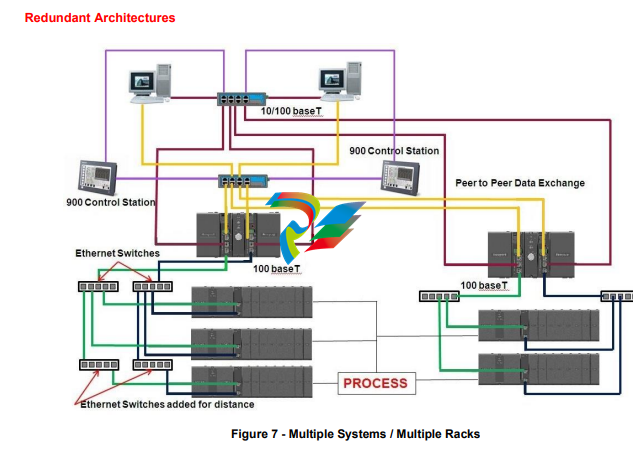

Redundant Architectures

Redundant Controller

Two redundant C75 CPUs operate in a separately

mounted controller rack, each with an independent

900PS1 model power supply. A Redundant Switch

Module (RSM) is located in the rack between the two

C75 CPUs. A key switch on the RSM allows the user

to change the operating mode of the Lead CPU. There

is no I/O in the controller rack; the CPUs communicate

with up to 12 racks of I/O over a 100 base-T Ethernet

physical communication link or fiber optics with an

external media converter for greater distance. When

more than one I/O rack is used in the system, Ethernet

switches are required, one port for each Scanner

connection. In operation, all control functions and host

communication exchanges are handled by the Lead

controller, including configuration and operator

changes. The Lead controller updates the Reserve

controller every scan cycle with all the information

needed to assume control in the event of a fault

condition.

After power-up of the C75 CPUs, the first available

CPU assumes the Lead function. The Lead may be

transferred to the Reserve controller by:

• Failure of the Lead controller,

• Manually changing a keyed switch located on

the Redundant Switch Module,

• Input pin on Redundancy Status function block, or

• Instruction from host communication.

Dual Networks for Host communications are provided on the

C75 CPU. Both network ports are continuously active on the

Lead controller. Matrikon OPC server is available from

Honeywell Matrikon to support dual Ethernet

communications and automatically transfer communications.

The C75 network ports may otherwise be used in nonredundant mode where only one of the communication ports

is used.

Remote I/O - To extend the distance between the CPU rack

and the most distant I/O rack to 300m (984 ft.) up to two

Ethernet switches may be used in each I/O connection.

Distances up to 40km are possible with fiber optic cable.

Operator Interface – The 900 Control Station Operator

Interfaces (900CR series) is supported with the C75 CPU.

An Ethernet connection is made to a switch connected to

the Ethernet port of each CPU. The operator interface

communication to the controller follows the Lead controller

assignment.

Status/Diagnostics - An output parameter of the system

monitor function block of C75 CPUs provides a digital status

of the Reserve controller to allow integration of this

information into the control strategy. C75 CPUs also provide

diagnostic status on redundancy operation that may be

observed using Designer configuration software. A

Redundancy status function block is also available to

monitor redundant controller operation.

Function Blocks

A large assortment of analog and digital function

blocks are available to solve the most demanding

control requirements. Function blocks are grouped by

scan rate, fast or normal, and by function, Principal or

Standard.

Function Block Execution - All function blocks

operate synchronously with I/O processing. Inputs are

measured at the start of every scan and outputs are

updated at the end of every scan. Function blocks

such as Time Proportioning Outputs (TPO) and

Position Proportioning outputs (PPO) require higher

output resolution and are updated when the function

blocks are executing. Micro-controllers on digital I/O

modules can maintain TPO duty cycle operation during

failsafe conditions. Micro-controllers on all I/O modules

allow outputs to be configured to assume a default

state in the event of a fault condition.

Normal Scan: Function blocks that execute during the

Normal Scan are synchronized to the analog input

measurements. The fastest update rate is 500ms.

100ms analog capable from version v6.300 and above.

Note: Low Level AI updates @ 0.5 sec.

Fast Scan: The fastest update rate for fast scan

function blocks in a single controller rack is 10ms. The

update rate starts at 25ms when remote racks are

used and for redundant systems.

Principal Function Blocks – These function blocks

are supported by dedicated Widget objects in Station

Designer software for configuring 900 Control Station

operator interfaces. They have Tag names and other

attributes to support on-line user interaction. Principal

function blocks can be used any number of times in a

configuration.

Typical Principal function blocks include PID, Set Point

Programming, Sequencers, Alternators, Stage, etc

Standard Function Blocks – The number of standard

function blocks that may be used in a configuration is

virtually unlimited. Typical Standard blocks include

totalizer, free-form math, average, mass flow, function

generator, periodic timers based on real-time, carbon

potential, RH, Dew Point, signal selection, comparison,

gas flow, real time clock, and many others. These

blocks may be configured to create control schemes

that precisely address the needs of your process.

Digital status outputs are also provided on many of the

analog function blocks to facilitate intelligent signal

alarming and default operation strategies.

Typical logic function blocks include AND, OR, XOR, NOT,

Latch, Flip-flop, On/Off Delay and Resettable timers,

Counters, Free-form Boolean logic and more. The execution

of analog and digital functions is seamlessly integrated into

a single control strategy in the controller.

AI-V – The new AI-V function blocks will allow 1oo2 and

2oo3 voting for inputs and compares its values with one

another and reports any deviation if validation between one

another fails. Output value is calculated by comparing all

inputs channels and selecting best of three.

DI-V - The new DI-V function blocks will allow 1oo2 and

2oo3 voting for inputs voting for inputs and compares its

values with one another and reports any deviation if

validation between one another fails. Output value is

calculated by comparing all inputs channels and selecting

best of three.

AO-V – The AO-V block is similar to the AO block but it

provides additional functionality which allows users to

validate the status of the output using a feedback input

channel. The primary function of this block is to validate the

feedback signal and provides indication when input fails to

match the output due to possible reasons such as field

power failure, cable failure, fuse etc. The function block will

also check the feedback input signal for input module error,

failed input channel and loss of feedback module

communications.

DO-V - The DO-V block is similar to the DO block but it

provides additional functionality which allows users to

validate the status of the output using a feedback input

channel. The primary function of this block is to validate the

feedback signal and provides indication when input fails to

match the output due to possible reasons such as field

power failure, cable failure, fuse etc. The function block will

also check the feedback input signal for input module error,

failed input channel and loss of feedback module

communications.

Alarms/Events

Alarms and events represent changes in digital status that

require user notification. The ControlEdge HC900 controller

supports an internal alarm annunciation system that may be

setup to operate via e-mail to a remote computer (see

Communications, E-mail Alarming). Up to 360 alarm points

per controller may be grouped in 30 groups of 12.

Events are digital status changes that cause messages to

be presented on the 900 Control Station operator interface.

Controller events may prompt e-mail messages,

do not require acknowledgement, and are reported and

logged in a separate group. Up to 64 event points are

supported in a controller.

Alarms and events are time stamped in the controller to a

one second resolution.

Sequence of Event (SOE)

SOE is a mechanism for recording and determining the

order (sequence) of digital state changes (on DI

channel). High-resolution SOE uses 1 msec time

stamping. SOE display tool (historian or control station)

shall map the SOE event properties from signal

number in configuration file.

Note:

• SOE is supported only in non-redundant UIO

configuration.

• As of now SOE events across controllers may not be

correlated properly as there is no time sync across

controllers

Configuration

Controller configuration is performed using Designer

Configuration software on a PC operating with

Windows™ 7 (32-bit and 64-bit), Windows™ 8.1 (32-bit

and 64-bit), Windows™ 10 (32-bit and 64-bit), Windows

Server 2016, and Windows Server 2019. Configuration

files are built independently on the PC and downloaded to

the controller in a separate operation.

Validation of proper physical I/O to support the

configuration is provided along with appropriate warnings.

Configuration Back-build - In the event a PC

configuration file is lost or misplaced, it can be easily

reconstructed using the upload function of the Designer

configuration software. Simply read the configuration

from the controller to exactly duplicate the original

configuration, including all text descriptions.

Configuration edit - In the event edits to a controller’s

configuration are required after the unit is in operation, an

uploaded file may be monitored during process operation,

edited, and downloaded with the on-line download function

of the Designer. The software allows configuration changes

while in the Run mode, limiting process disturbances.

Note: Forcing and downloads cannot be made on Safety

controllers unless they are switched to the RUN/PROGRAM mode.

I/O Redundancy

CAUTION: For I/O redundancy, prefabricated cable length

from RTP to Redundant UIO modules must be same.

• Flexibility in configuration

• I/O Redundancy RTP (Model No – 900RTI-0100)

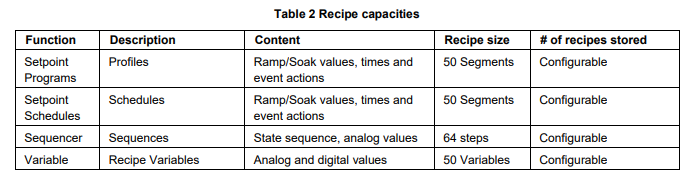

Recipes

Recipes are groups of data defined by the user that are

used to make multiple value changes in the controller

through a single action. Function block types that accept

recipe data and the quantity of recipes stored in the

controller are listed in Table 2.

Recipes may also include Variables, which are dynamic

analog and digital values used as inputs to standard and

principal function blocks. Recipes may be loaded through

the 900 Control Station operator interface by name or

number, or via a dedicated recipe load function block and

user configured logic.

Operator Interfaces

A ControlEdge HC900 controller can support up to three

900 Control Station operator interfaces via Ethernet or

Serial communications. The interface is configured with

Station Designer software using a database

import function to simplify the setup. See specification

sheet 51-52-03-102 for more information on this

interface.

Note: The old phased-out Control Stations (900CS10-

00/ 900CS15-00) will not support import of HC900

software configuration file (*.cde) v7.1 and above. For

HC Designer v7.1 and above please migrate to new

900CR series Control Stations with Station Designer

v3.1.7100 and above.

Communications

HART IP – The HC900 controller supports industry

standard HART (Highway Addressable Remote

Transducer) protocol to integrate with asset manager

(Currently it is qualified with Honeywell FDM).

HART supports two functionalities:

• HART IP client (FDM) communication

• HART Function Block communication

The controller enables the HART IP client to exchange

information with HART field devices connected to the

Al/AO channels in the controller via a HART-IP Server.

Multiple HART IP clients can be served by the

controller at the same time. When the HART IP client

builds a HART command request and sends it to the

TCP/IP port of the HART-IP server, the HART-IP

server responds to the HART IP client with information

from the field device. Since it takes time for the

controller to communicate with the field devices

through onboard or remote I/O cards, a delayed

response mechanism is implemented. The TCP /IP

port of the HART-IP server is user-configurable and

the default port number is 5094. The end user may

change the port number if firewall configuration is

required.

The controller enables HART function blocks to access

to the HART field devices through HART-enabled

Al/AO channels. Currently HART command 3,

command 48 and command X are implemented.

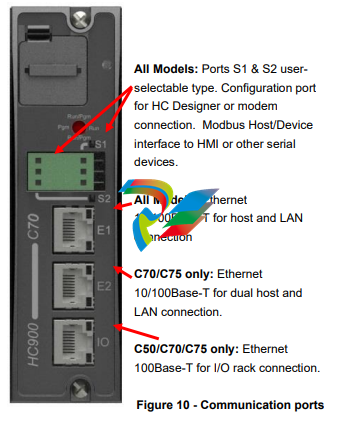

Remote I/O Rack Port (C50, C70, C75) – An Ethernet

port is dedicated to supporting remote I/O racks. This

10/100Base-T Connection on the C50 and C70 CPU

supports a single direct connected remote rack or up

to 11 remote racks when connected through an

external Ethernet switch. The C75 CPU supports a

single direct connected rack or up to 12 remote racks

using external switches.

User Interface Support – The 900 Control Station interface

may be connected via Ethernet or serial communications. Up

to three interfaces may be connected to a controller for

distances up to 328 feet (100Meters) via Ethernet or 2000

feet (609 meters) between the controller and operator

interface. 3rd party user Interface support is provided through

an isolated RS485 port connection using Modbus/RTU

protocol, or Ethernet with Modbus/TCP protocol.

Ethernet Modbus/TCP Communications –

ControlEdge HC900 controllers communicate with their host

PC interfaces over an Ethernet 10/100Base-T communication

network using the Modbus/TCP protocol, an open protocol

interface available for most popular HMI software packages.

The controllers Ethernet ports are MDIX and configured to

auto negotiate and will default to half duplex if host fails to

negotiate. The C30 supports up to 5 host connections while

the C50/C70/C75 support up to 10 concurrent host

connections over an Ethernet network for control supervision

and data acquisition. The Designer software can also address

any of the controllers concurrently over Ethernet for

configuration monitoring, diagnostic interrogation, upload/

download, or on-line configuration changes. As a result, a

ControlEdge HC900 network of controllers and operator

interfaces can be partitioned into process segments to assure

proper control performance. Each of these process segments,

in turn, can be accessed via common HMI software within the

plant environment using an Ethernet LAN.

Ethernet Peer to Peer Communications - Peer data

communications between one ControlEdge HC900 controller

and up to 32 other ControlEdge HC900 controllers is

supported over Ethernet via UDP protocol for safety/process

data sharing. Both digital and analog data exchange are

supported using peer data exchange function blocks, up to

2240 (max 44 peer writes per modbus device) parameters

between peer controllers. For SIL variants the safety peer

function blocks can be used for Safety peer communication

along with peer data exchange function blocks. No

specialized software is required. Peer data can be given

signal tag references for use in a control or data acquisition

strategy. Peer to peer data interchange does not consume

one of the host connections.

Serial Modbus RTU Communications - Serial Modbus

RTU communications is available on the isolated RS485 (2

wire) ports of the ControlEdge HC900 Controller CPU

assembly in a Modbus Host or Device mode. The protocol of

these ports is user selectable between ELN protocol for use

with HC Designer software or Serial Modbus to interface

with other compatible devices.

Modbus RTU Device - Isolated RS485 ports

may be configured for simultaneous operation as a

Modbus device port to allow each to communicate with

a single Modbus host.

The Modbus protocol supports read and write access

to a default address map of certain function blocks and

parameters.

In configurations 4.0 and later, a map of customized

addresses, blocks and parameters can be created

either by editing the default map or from scratch.

In the default map (fixed), a 4000 register array is

available to allow the user to specify the address

locations of specific controller data to optimize

controller communications.

The data in the array may also be accessed in user

specified formats (data types) such as analog data in

Float 32, unsigned 16, signed 16, unsigned 32, signed

32, and digital data in signed 16 or unsigned 16.

The data type selections in the 4000 register array

provide compatibility with devices such as 3rd party

touch panels. In the custom map, all data formats are

adjustable.

Modbus RTU Host - Either of the ports may be

configured as a Modbus RTU host, one per controller.

Up to 32 devices may be multi-dropped on the isolated

RS485 port. Function blocks are available in the

ControlEdge HC900 controller to allow the user to

specify read and write operations to up to 32 external

Modbus compatible modus device devices and up to

1024 data points.

Modbus TCP Initiator – The Ethernet ports may be

configured as a Modbus TCP initiator. Function blocks

are available in the ControlEdge HC900 controller to

allow the user to specify read and write operations to

compatible modbus device devices for up to 1024 data

points.

Profibus – The ControlEdge HC900 can access data from

Profibus modbus device devices using a Modbus-toProfibus gateway device attached to the serial port of the

controller. The gateway device is a Profibus Host on the

fieldbus network and a Modbus device to the ControlEdge

HC900. The Profibus data is connected into the control

strategy using Modbus function blocks. This application has

been validated with a ProLinx 5104-MCM-PDPM gateway

(from ProSoft® Technology).

E-mail Alarms/Events--ControlEdge HC900 alarms or

events can be individually configured to send an e-mail

alarm (or event) message to e-mail addresses with the

assigned alarm priority.

• Number of e-mail addresses: 3 based on alarm

priority

• From: Controller name (up to 16 characters)

• Subject: text (up to 32 characters)

• Content: date and time of alarm/event, alarm/event

tag name, alarm/event state

• Message: 48 character text (for alarms only)

• Priority Levels: 4 for alarms, 1 for events

Controller Configuration Access –Designer software

supports communicating with ControlEdge HC900

controllers using an Ethernet or serial connection using ELN

protocol to support direct PC connection for configuration

upload, download, debug and maintenance. Modbus RTU

protocol is also supported through the serial port interface.

Once the ControlEdge HC900 controller has been

configured using Designer Software, on-line configuration

changes

may be made while maintaining process control.

Configurations may also be loaded into the controller via the

Ethernet TCP/IP network from a host PC. On-line monitoring

for program debug and on-line program edit functions are

also supported via the Ethernet port.

Modem Access – Communications to the

ControlEdge HC900 controller may be via an external

modem connected to the controller’s using an

RS485/RS232 converter. HC Designer software

supports configuration upload, download and on-line

edits via modem. When modem communication is

selected, Modbus RTU communication timeouts are

extended.

Experion Supervisory Software – Honeywell’s

Windows 10 version is available when PC-based

supervisory control and data acquisition is required.

Ethernet network interface to an Experion server is via

the controller host Ethernet 100 Base-T port using

Modbus/TCP protocol. Client Stations over Ethernet

allow multiple user access to a ControlEdge HC900

network. Using the large selection of standard

operating display templates in Experion saves

development time. When further customization is

needed, the full graphic display development

environment of Experion may be used to fully animate

your process supervisory displays.

A batch reporting option is offered in Release 500 and

430 which enables batch reports to be created using a

standard template. User-entered lot data is supported

and up to 50 parameters can be defined for batch

logging. The file can be exported in .csv format using a

lot number-encoded filename.

SpecView32 Supervisory Software – SpecView32

software can be used as a supervisory interface for

thermal-based applications, offering historical trending,

batch reporting, recipe development involving setpoint

programs and simplified graphics configuration.

ControlEdge HC900 parameters are simply selected

from categorized lists for placement on userconfigured displays or onto display objects.

Network connection is via the controller host Ethernet

10/100Base-T port using Modbus/TCP protocol. A

variety of Windows operating environments are

supported.

OPC Server – Network communication access to

ControlEdge HC900 controllers through third party PC

interfaces is simplified with Honeywell’s Matrikon OPC

server software program. This software supports the

Modbus/TCP interface to either redundant or non-redundant

ControlEdge HC900 controllers. In redundant applications,

Matrikon OPC Server software supports dual Ethernet

connections to both C75 CPUs. Communications to the

controller is maintained during a single network failure

and/or following the transfer of the Lead function from one

CPU to another. Compatible OPC client programs can use

the Ethernet connection to the ControlEdge HC900 via

Honeywell’s OPC Server for remote supervision, data

collection or other supervisory functions.

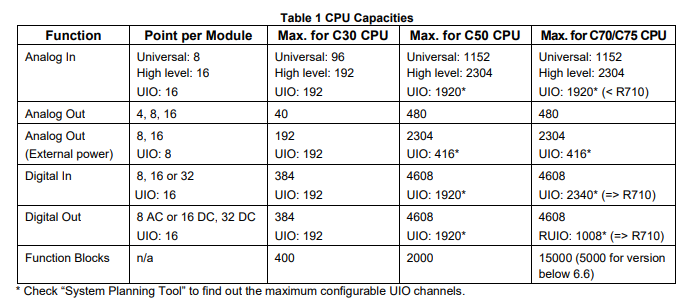

Capacity

The capacity of the ControlEdge HC900 system is

determined by the type of CPU selected, the quantity

of I/O racks, the quantity’s type of I/O modules, the

update rate (scan rate) required, and CPU memory. In

most applications, the CPU memory limit has a low

probability of limiting capacity.

How many I/O channels?

Number of I/O is limited only by physical space.

Namely, the number of racks, the number of modules

per rack, and the number of channels in the modules.

In general,

Maximum I/O channels = (max. number of I/O racks) x

(max. number of modules in each rack) x

(max. number of channels per module)

Examples

Maximum C30 I/O = 1 rack x 12 modules x 32

channels per module = 384 I/O channels

Maximum C50, C70, C75 I/O = 12 racks x 12 modules

per rack x 32 channels per module = 4608 I/O channels.

Maximum C75 Redundant UIO = 6 Redundant racks

(12 racks) x 12 modules per rack x 14 channels per

module = 1008 I/O channels.

How many function blocks (loops, programmers,

etc.)?

Fixed limits are not imposed on function block types.

Your configuration can probably contain as many of

each function block as needed. The limit is reached

when either

a) Dynamic memory is full or

b) Maximum function block quantity is reached or

c) Configuration memory is full or

d) Over 65,535 block configuration parameters or

block inputs used (but not Block Outputs).

These limits are explained below.

a) Dynamic Memory

The rule of thumb is: Max. number of function blocks =

Dynamic memory ÷ memory per function block

The smaller the function block, the more of them can fit

in your configuration.

b) Quantity

Memory limitation is not for function blocks.

Complex blocks such as PID, Programmer, and

Scheduler Sequencer use more memory than simpler

blocks like On/Off, Device Control, Auto/Manual Bias.

For example, several thousand Auto/Manual Bias

blocks would fit in the C30’s memory if not for the quantity

limit of 400.

Conversely, about 300 Scheduler blocks will consume all

the C30’s memory despite the higher quantity limit of 400.

Scan Time Consideration

Another consideration when configuring function blocks is

scan time and the potential for CPU scan time to become

insufficient for the application.

The scan time of a controller increases in fixed increments.

As function blocks are added to a configuration, the time

needed to execute the total configuration is recalculated. If

additional time is needed, the scan time will be increased to

the next increment in sequence. (See Specification section

for scan time increments)

How many recipes in my pool?

Unlike with function blocks, there is no quantity limit to

recipes. The only limiting factor to recipe pool size is

available memory. Whatever memory is unused by the rest

of your configuration (that is, function blocks) can be

allocated for recipes. As long as memory is available,

allocate as many recipes as needed.

The rule of thumb is

Max. number of recipes = Recipe memory allocation ÷

memory per recipe

Configuration memory allocation

The configuration memory comprises one allocation for the

function block configuration and one allocation for recipes.

In general,

Total configuration memory =

Configuration + Recipe allocation

Whatever memory has not been allocated to recipes is

available for your configuration. By changing the size of the

recipe pool allocation, you control the amount of memory

available for recipes and therefore configuration. Need a

small configuration but many recipes? Allocate more recipe

space. Need a large configuration but few recipes?

Allocate less recipe space

Where are usage/capacities presented?

File Properties in Designer displays statistics on

usage/availability of:

• configuration memory (recipes + function

block configuration),

• dynamic memory (function block configuration

only)

• fast scan time,

• Normal scan time,

• Normal CPU% used,

• Fast CPU% used,

• Each component of a configuration (variables,

constants, etc.).

Controller Data Storage

The controller may log process data values in the available

memory that is not used by the configuration. Up to 250

signal values may be logged in a rotating buffer using three

different sample rates with oldest data being replaced with

new data after the buffer is full.

Data is extracted from the controller using HC Historian data

harvesting software via Ethernet or Serial connection.

.png)

.png)

.png)