HoneywellControlEdge HC900 Controller Specifications 51-52-03-31, January 2022

Redundant Power - A second (backup) power module may

be added to each ControlEdge HC900 controller rack. An

extended rack is available that expands the standard 8 and

12 I/O rack to accommodate a second (redundant) power

supply and power status module.

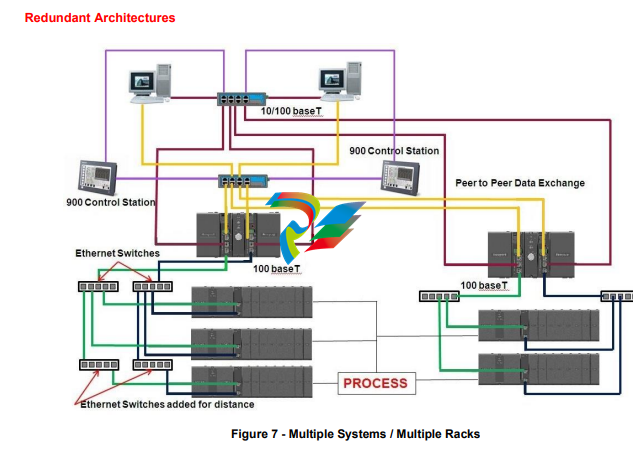

Redundant Architectures

Redundant Controller

Two redundant C75 CPUs operate in a separately

mounted controller rack, each with an independent

900PS1 model power supply. A Redundant Switch

Module (RSM) is located in the rack between the two

C75 CPUs. A key switch on the RSM allows the user

to change the operating mode of the Lead CPU. There

is no I/O in the controller rack; the CPUs communicate

with up to 12 racks of I/O over a 100 base-T Ethernet

physical communication link or fiber optics with an

external media converter for greater distance. When

more than one I/O rack is used in the system, Ethernet

switches are required, one port for each Scanner

connection. In operation, all control functions and host

communication exchanges are handled by the Lead

controller, including configuration and operator

changes. The Lead controller updates the Reserve

controller every scan cycle with all the information

needed to assume control in the event of a fault

condition.

After power-up of the C75 CPUs, the first available

CPU assumes the Lead function. The Lead may be

transferred to the Reserve controller by:

• Failure of the Lead controller,

• Manually changing a keyed switch located on

the Redundant Switch Module,

• Input pin on Redundancy Status function block, or

• Instruction from host communication.

Dual Networks for Host communications are provided on the

C75 CPU. Both network ports are continuously active on the

Lead controller. Matrikon OPC server is available from

Honeywell Matrikon to support dual Ethernet

communications and automatically transfer communications.

The C75 network ports may otherwise be used in nonredundant mode where only one of the communication ports

is used.

Remote I/O - To extend the distance between the CPU rack

and the most distant I/O rack to 300m (984 ft.) up to two

Ethernet switches may be used in each I/O connection.

Distances up to 40km are possible with fiber optic cable.

Operator Interface – The 900 Control Station Operator

Interfaces (900CR series) is supported with the C75 CPU.

An Ethernet connection is made to a switch connected to

the Ethernet port of each CPU. The operator interface

communication to the controller follows the Lead controller

assignment.

Status/Diagnostics - An output parameter of the system

monitor function block of C75 CPUs provides a digital status

of the Reserve controller to allow integration of this

information into the control strategy. C75 CPUs also provide

diagnostic status on redundancy operation that may be

observed using Designer configuration software. A

Redundancy status function block is also available to

monitor redundant controller operation.

Function Blocks

A large assortment of analog and digital function

blocks are available to solve the most demanding

control requirements. Function blocks are grouped by

scan rate, fast or normal, and by function, Principal or

Standard.

Function Block Execution - All function blocks

operate synchronously with I/O processing. Inputs are

measured at the start of every scan and outputs are

updated at the end of every scan. Function blocks

such as Time Proportioning Outputs (TPO) and

Position Proportioning outputs (PPO) require higher

output resolution and are updated when the function

blocks are executing. Micro-controllers on digital I/O

modules can maintain TPO duty cycle operation during

failsafe conditions. Micro-controllers on all I/O modules

allow outputs to be configured to assume a default

state in the event of a fault condition.

Normal Scan: Function blocks that execute during the

Normal Scan are synchronized to the analog input

measurements. The fastest update rate is 500ms.

100ms analog capable from version v6.300 and above.

Note: Low Level AI updates @ 0.5 sec.

Fast Scan: The fastest update rate for fast scan

function blocks in a single controller rack is 10ms. The

update rate starts at 25ms when remote racks are

used and for redundant systems.

Principal Function Blocks – These function blocks

are supported by dedicated Widget objects in Station

Designer software for configuring 900 Control Station

operator interfaces. They have Tag names and other

attributes to support on-line user interaction. Principal

function blocks can be used any number of times in a

configuration.

Typical Principal function blocks include PID, Set Point

Programming, Sequencers, Alternators, Stage, etc

Standard Function Blocks – The number of standard

function blocks that may be used in a configuration is

virtually unlimited. Typical Standard blocks include