HoneywellControlEdge HC900 Controller Specifications 51-52-03-31, January 2022

Note: Forcing and downloads cannot be made on Safety

controllers unless they are switched to the RUN/PROGRAM mode.

I/O Redundancy

CAUTION: For I/O redundancy, prefabricated cable length

from RTP to Redundant UIO modules must be same.

• Flexibility in configuration

• I/O Redundancy RTP (Model No – 900RTI-0100)

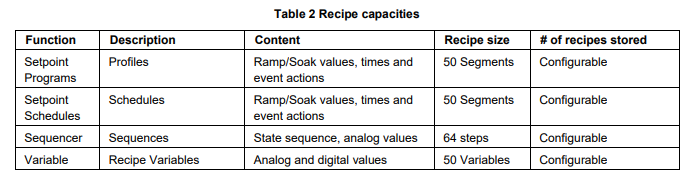

Recipes

Recipes are groups of data defined by the user that are

used to make multiple value changes in the controller

through a single action. Function block types that accept

recipe data and the quantity of recipes stored in the

controller are listed in Table 2.

Recipes may also include Variables, which are dynamic

analog and digital values used as inputs to standard and

principal function blocks. Recipes may be loaded through

the 900 Control Station operator interface by name or

number, or via a dedicated recipe load function block and

user configured logic.

Operator Interfaces

A ControlEdge HC900 controller can support up to three

900 Control Station operator interfaces via Ethernet or

Serial communications. The interface is configured with

Station Designer software using a database

import function to simplify the setup. See specification

sheet 51-52-03-102 for more information on this

interface.

Note: The old phased-out Control Stations (900CS10-

00/ 900CS15-00) will not support import of HC900

software configuration file (*.cde) v7.1 and above. For

HC Designer v7.1 and above please migrate to new

900CR series Control Stations with Station Designer

v3.1.7100 and above.

Communications

HART IP – The HC900 controller supports industry

standard HART (Highway Addressable Remote

Transducer) protocol to integrate with asset manager

(Currently it is qualified with Honeywell FDM).

HART supports two functionalities:

• HART IP client (FDM) communication

• HART Function Block communication

The controller enables the HART IP client to exchange

information with HART field devices connected to the

Al/AO channels in the controller via a HART-IP Server.

Multiple HART IP clients can be served by the

controller at the same time. When the HART IP client

builds a HART command request and sends it to the

TCP/IP port of the HART-IP server, the HART-IP

server responds to the HART IP client with information

from the field device. Since it takes time for the

controller to communicate with the field devices

through onboard or remote I/O cards, a delayed

response mechanism is implemented. The TCP /IP

port of the HART-IP server is user-configurable and

the default port number is 5094. The end user may

change the port number if firewall configuration is

required.

The controller enables HART function blocks to access

to the HART field devices through HART-enabled

Al/AO channels. Currently HART command 3,

command 48 and command X are implemented.

Remote I/O Rack Port (C50, C70, C75) – An Ethernet

port is dedicated to supporting remote I/O racks. This

10/100Base-T Connection on the C50 and C70 CPU

supports a single direct connected remote rack or up

to 11 remote racks when connected through an

external Ethernet switch. The C75 CPU supports a

single direct connected rack or up to 12 remote racks

using external switches.

User Interface Support – The 900 Control Station interface

may be connected via Ethernet or serial communications. Up

to three interfaces may be connected to a controller for

distances up to 328 feet (100Meters) via Ethernet or 2000

feet (609 meters) between the controller and operator

interface. 3rd party user Interface support is provided through

an isolated RS485 port connection using Modbus/RTU

protocol, or Ethernet with Modbus/TCP protocol.

Ethernet Modbus/TCP Communications –

ControlEdge HC900 controllers communicate with their host

PC interfaces over an Ethernet 10/100Base-T communication

network using the Modbus/TCP protocol, an open protocol

interface available for most popular HMI software packages.

The controllers Ethernet ports are MDIX and configured to

auto negotiate and will default to half duplex if host fails to

negotiate. The C30 supports up to 5 host connections while

the C50/C70/C75 support up to 10 concurrent host

connections over an Ethernet network for control supervision

and data acquisition. The Designer software can also address

any of the controllers concurrently over Ethernet for

configuration monitoring, diagnostic interrogation, upload/

download, or on-line configuration changes. As a result, a

ControlEdge HC900 network of controllers and operator

interfaces can be partitioned into process segments to assure

proper control performance. Each of these process segments,

in turn, can be accessed via common HMI software within the

plant environment using an Ethernet LAN.

Ethernet Peer to Peer Communications - Peer data

communications between one ControlEdge HC900 controller

.png)

.png)

.png)